Preparation method and preparation device of isotropic pitch coke

A production method and isotropic technology, applied in the field of isotropic pitch coke production methods and production devices, can solve the problems of lengthy isotropic graphite process, achieve low porosity, short residence time, and avoid lengthy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

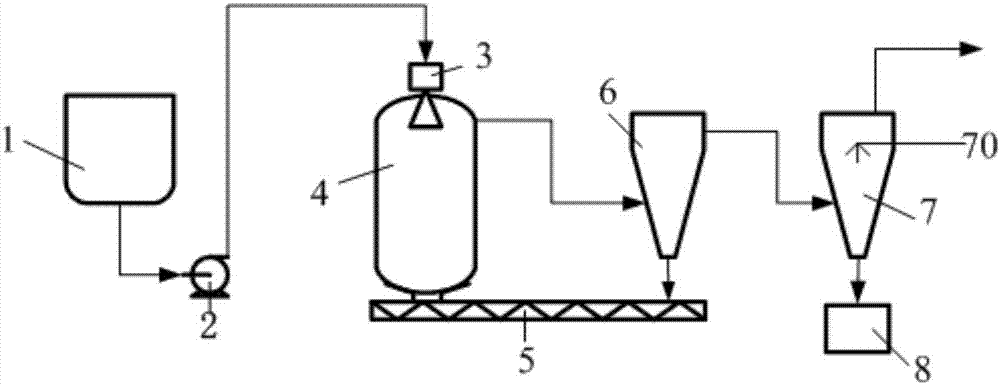

[0043] use figure 1 The production device shown produces isotropic pitch coke, and the specific production process includes:

[0044] Heating coal liquefied asphalt with a softening point of 150°C to 300°C to obtain molten asphalt, transported to the atomizer by the feed pump for atomization, and then enters the pyrolysis tower for contact carbonization with high-temperature gas at a temperature of 1200°C to obtain isotropic Pitch coke, and the isotropic pitch coke that is not mixed with oil and gas passes through the first outlet of the pyrolysis tower to the pitch coke collection equipment, and the mixture of pyrolyzed oil gas, high-temperature gas and isotropic pitch coke is discharged from the pyrolysis tower The second outlet discharges into a high temperature cyclone separator.

[0045] The cyclone separator separates isotropic pitch coke from oil gas and high-temperature gas, and the separated isotropic pitch coke reaches the pitch coke collection equipment through the...

Embodiment 2

[0047] The difference from Example 1 is that the pitch is coal tar pitch, its softening point is 270°C, and it melts at 380°C to become molten pitch, and the temperature of the high-temperature gas is 1400°C.

Embodiment 3

[0049] The difference from Example 1 is that the asphalt is petroleum asphalt, its softening point is 200°C, and it melts at 350°C to become molten asphalt, and the temperature of the high-temperature gas is 1100°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com