Preparation method of mesophase pitch continuous filaments

A technology of mesophase pitch and filament, which is applied in the field of preparation of mesophase pitch continuous filaments, can solve the problems of high fiber brittleness, large fiber bundle damage, slow spinning speed, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

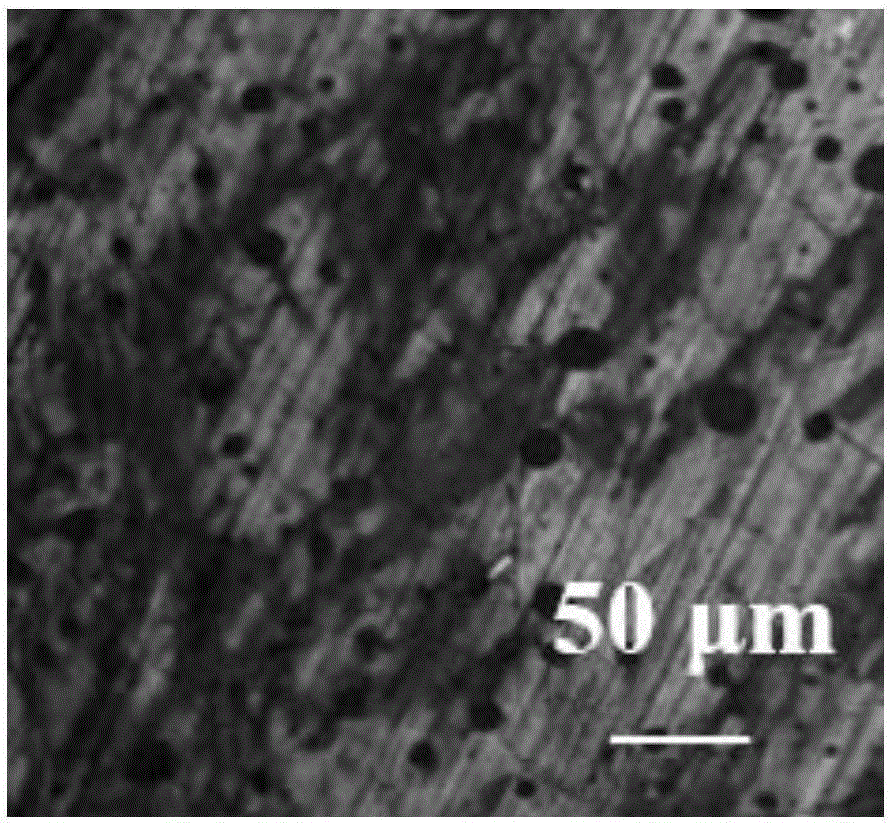

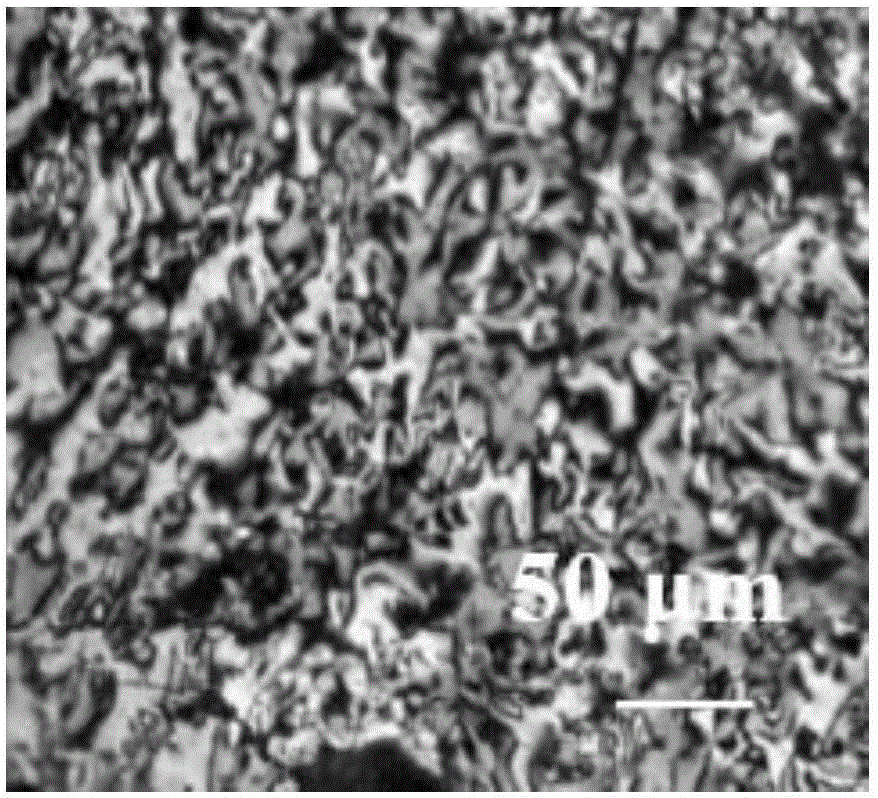

[0030] A method for preparing continuous filaments of mesophase pitch, adding a small amount of incompatible isotropic naphthalene pitch close to the softening point in the mesophase component of 95 wt% mesophase naphthalene pitch, that is, the isotropic naphthalene pitch The content is 10wt% of the sum of mesophase naphthalene pitch and isotropic naphthalene pitch, the ash content in isotropic naphthalene pitch is 5wt%, and the softening point close means that the softening points of mesophase naphthalene pitch and isotropic naphthalene pitch are different 10°C, heated by twin-screw to 40°C above the softening point of mesophase pitch, melted and blended, and then passed through the SV static mixer, the heating temperature is 40°C above the softening point of mesophase pitch ( figure 2 It is a polarized light micrograph of the blended raw materials blended by a twin-screw-static mixer. A large number of wedge-shaped dislocation structures appear in the intermediate domain str...

Embodiment 2

[0032] A method for preparing continuous filaments of mesophase pitch, adding a small amount of incompatible isotropic methylnaphthalene pitch close to the softening point in the mesophase component of 96wt% mesophase methylnaphthalene pitch, that is, isotropic The content of isotropic methyl naphthalene pitch is 9wt% of the sum of mesophase methyl naphthalene pitch and isotropic methyl naphthalene pitch, and the ash content in isotropic methyl naphthalene pitch is 4wt%. The softening point difference between base naphthalene pitch and isotropic methyl naphthalene pitch is 18°C. After being heated by twin-screws to 30°C above the softening point of mesophase pitch, it is melted and blended, and then passed through a SK static mixer. The heating temperature is mesophase Methyl naphthalene pitch is 50°C above the softening point of the pitch, and then spun after metering. The spinning process is as follows: the spinning temperature is 50°C above the softening point of the mesopha...

Embodiment 3

[0034] A method for preparing continuous filaments of mesophase pitch, adding a small amount of incompatible isotropic coal tar pitch with a close softening point to mesophase coal tar pitch with a mesophase component of 97 wt%, that is, isotropic coal tar pitch The content of tar pitch is 8wt% of the sum of mesophase coal tar pitch and isotropic coal tar pitch, the ash content in isotropic coal tar pitch is 3wt%, and the softening point close means that mesophase coal tar pitch and isotropic The softening point of coal tar pitch differs by 16°C. After being heated by twin-screws to 20°C above the softening point of mesophase coal tar pitch, it is melted and blended, and then passed through an SX static mixer, and the heating temperature is above the softening point of mesophase coal tar pitch. 40°C, and then spinning after metering. The spinning process is: the spinning temperature is 50°C above the softening point of the mesophase pitch, the spinning pressure is 1.5MPa, the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com