Method for manufacturing high thermal conductivity pitch-based carbon fiber composite material prefabricated body

A pitch-based carbon fiber, composite material technology, applied in heating/cooling fabrics, non-woven fabrics, textiles and papermaking, etc., can solve the problems of non-woven, fiber slippage, and limited size of special-shaped parts, and achieve easy dredging and Conduction, body shape complete and compact, the effect of increasing carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment is a specific implementation of the present invention, specifically the following steps:

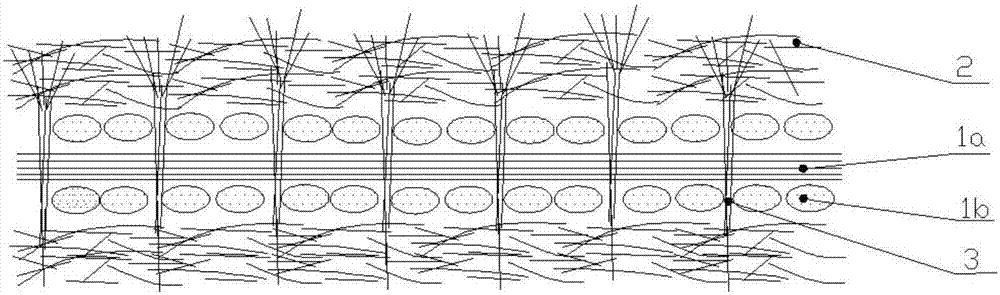

[0031] (1) Prepare a unidirectional non-woven fabric with a diameter of 5 μm and a 0.1K high thermal conductivity pitch-based pre-oxidized wire, with a thickness of 0.2 mm and an area density of 50 g / m 2 , forming a continuous layer; cut the PAN-based carbon fiber pre-oxidized wire into 20mm, and comb it into a pre-oxidized wire mesh tire with a carding machine, with a thickness of 0.05mm and an area density of 15g / m 2 ;The two are stacked continuously and alternately, and the angle between no weft cloth is 0° / 0°, wherein the weight ratio of the continuous layer to the mesh layer is 60:40, and K represents the number of thousands of tows;

[0032] (2) Introduce Z-direction fibers in the axial direction of the short-fiber mesh tire and the continuous non-woven fabric lay-up through the needling technology, and the needling density is controlled at 10 needles / cm 2 ,...

Embodiment 2

[0037] (1) The 2K high thermal conductivity pitch-based carbon fiber with a diameter of 20 μm and a low-temperature carbonization treatment at 400 °C was prepared into a unidirectional non-woven fabric with a thickness of 0.3 mm and an area density of 200 g / m 2, to form a continuous layer; cut the PAN carbon fiber pre-oxidized wire into 70mm, and comb it into a pre-oxidized wire mesh tire with a carding machine, with a thickness of 0.3mm and a surface density of 90g / m 2 ;The two are continuously and alternately laminated, and the angle between no weft cloth is 0° / 0°, and the weight ratio of continuous carbon fiber to net tire is 80:20;

[0038] (2) Introduce axial fibers through the needle punching technology in the axial direction of the short fiber mesh tire and the continuous non-woven fabric layup, and the needle punching density is controlled at 20 needles / cm 2 , made with a bulk density of 0.50g / cm 3 The quasi-three-dimensional prefabricated body blank;

[0039] (3) Pu...

Embodiment 3

[0041] (1) The 12K high thermal conductivity pitch-based carbon fiber with a diameter of 100 μm and a low-temperature carbonization treatment at 400 °C was prepared into a unidirectional non-woven fabric with a thickness of 0.5 mm and an area density of 400 g / m 2 ;Cut T700-12KPAN carbon fiber into 150mm, and comb it into pre-oxidized wire mesh tire with a carding machine, with a thickness of 0.5mm and a surface density of 200g / m 2 ;The two are laminated continuously and alternately, the angle between no weft cloth is 0° / 90°, and the weight ratio of continuous carbon fiber to net tire is 95:5;

[0042] (2) Introduce axial fibers through the needle-punching technology in the axial direction of the short-fiber mesh tire and the continuous non-woven fabric layup, and the needle-punching density is controlled at 50 needles / cm 2 , made with a bulk density of 0.75g / cm 3 The quasi-three-dimensional prefabricated body blank;

[0043] (3) Place the preform blank under the protection o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com