Manufacture of carbon composites by hot pressing

a carbon composite and hot pressing technology, applied in the direction of friction lining, braking drum, transportation and packaging, etc., can solve the problems of increasing weight, increasing the cost of composites, increasing the cost of many applications, etc., to improve oxidation stability, improve machinability, and improve the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Carbon / Carbon Composite Made by Dry Mixing of Precursor Materials

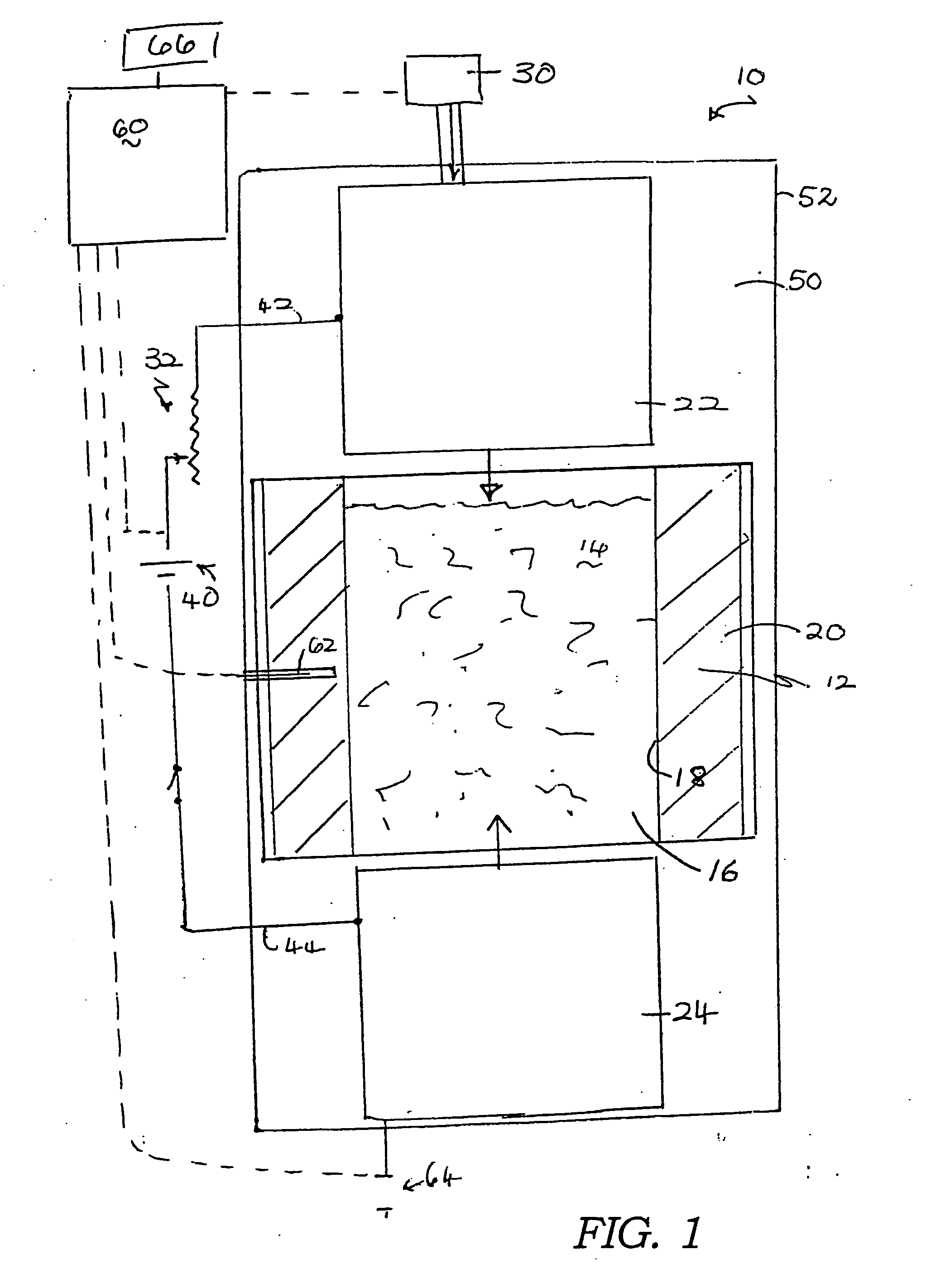

[0091] Mesophase pitch-based carbon fibers and a matrix material of milled pitch with 170° C. Mettler softening point (“SP”) (ASTM D 3104) and 70% coking yield were dry mixed at ambient temperature in a Sigma-type blender or similar type of mixer for about 5-15 minutes. The ratio of fibers to pitch matrix material was from 50-80 wt % fiber: 20-50 wt % pitch. The mixture was collected and charged into a mold box cavity (dimensions approximately 23×20 cm) of a hot press, as illustrated in FIG. 1. A pressure of up to about 140 kg / cm2 was applied to the mixture in the press. After pressing to compact the mixture, an electric current of about 1000-2000 amps (a power input of about 30-60 kW / kg) was passed through the mixture. The mix was held under the temperature and pressure conditions for about 5-10 minutes. The temperature of the mixture reached 800-900° C. This hot pressing process carbonizes and densifies the fiber / ma...

example 2

Carbon / Carbon Composite Made by Hot Mixing of Precursor Materials

[0092] Various batches of mesophase pitch-based carbon fibers and a matrix material of milled pitch from Example 1 were hot mixed at a temperature of about 200° C. in a Sigma-type blender or similar type of mixer for about 30-45 minutes. The ratio of fibers to pitch matrix material was varied from about 50-80 wt % fiber: 20-50 wt % pitch. During the hot mixing, the matrix material coated the fibers uniformly. The mixture was collected and charged into a mold box cavity of a hot press, and heated and pressed as described for Example 1. Alternatively, the mixture was compacted in a separate mold to a density of between about 0.5 and 1.0 g / cm3 prior to hot pressing.

[0093] A pressure of up to 140 kg / cm2 was applied to the mixture in the hot press. After pressing to compact the mixture, an electric current as high as 1500-2000 A (a power input of about 45-60 kW / kg) was passed through the mixture. The mix was held under th...

example 3

Silicon Carbide Carbon / Carbon Composite Made by Hot Mixing of Precursor Materials

[0104] Direct Addition of Solid SiC.

[0105] Blends of silicon carbide powder with an average particle size of about 10-20 microns from Alfa Aesar Company were blended with mixtures of chopped mesophase pitch carbon fiber and a 170° C. SP coal tar pitch by stirring at about 220° C. The mesophase pitch carbon fibers were about ¼-inch long obtained from Mitsubishi Chemical Corp. The following blend compositions were prepared, as shown in TABLE 3-1:

TABLE 3-11234Carbon fiber77%69% 69%62.5%Matrix19.2% 27.6% 17.2% 25%SiC3.8% 3.4% 13.8%12.5%

[0106] The blends were hot pressed to produce carbonized 3 cm thick carbonized composites with dimensions of 23 cm×23 cm. The densities measured for the as-pressed composites were: (1)=1.52, (2)=1.53, (3)=1.55, and (4)=1.55 g / cc. The composites impregnated with petroleum pitch and then rebaked to 900° C. and the impregnation and rebake steps were repeated. After the 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com