Method for killing out yellow Junshan needle tea

A technology for fixing Junshan silver needles, which is applied in the field of fixing Junshan silver needles with an oven, can solve the problems of unstable quality of Junshan silver needles, difficulty in controlling the degree of fixing, and difficult yellowing of color, and achieve yellowish brown and bright soup color. The effect of bright apricot yellow and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] This embodiment includes the following steps;

[0018] (1) Harvesting fresh leaves of raw materials: Harvesting buds of tea trees in Yueyang Junshan Island tea garden, the buds are 25-30mm long, 3-4mm wide, and the petioles are 2-3mm long;

[0019] (2) Withering: Thinly spread the harvested fresh leaf raw materials, spread them in the withering tank, the thickness of the spread leaves is 3-4cm, wither naturally, turn the leaves twice in the middle, and the withering time is 5 hours;

[0020] (3) Food oven finishing: install a movable finishing screen in the oven, the mesh aperture is 70 mesh, and the amount of leaves per layer is 0.5Kg, which is evenly distributed. Each layer is heated separately at a heating temperature of 260°C. The time is 4.5min, and the color of the bud head turns yellow after the lower leaves are completed;

[0021] (4) Breeze: Spread the green buds thinly on a thin bamboo tray, use an electric fan to quickly dissipate the air, and let it cool fo...

Embodiment 2

[0031] The difference between this example and Example 1 lies in: step (2), the leaves are turned once in the middle, and the withering time is 4 hours; step (3), the heating temperature of the food oven is 275°C, and the time for finishing is 4 minutes; step (4) uses The electric fan quickly dissipates heat and spreads the cooling time for 19 minutes; step (5) initial drying temperature is 102°C, time is 7 minutes, and then bakes down when the water content is 51.5wt%, and then cools down for 22 minutes. The rest are the same as embodiment 1.

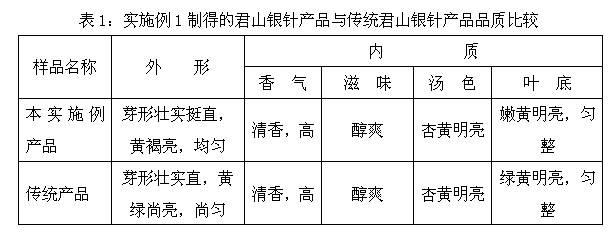

[0032] The quality of the Junshan Yinzhen product obtained in this embodiment is very close to that of the Junshan Yinzhen product obtained in Example 1 shown in Table 1, and it is difficult to distinguish it by the senses. This shows that the Junshan Yinzhen product prepared by the present invention has stable product quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com