Slow-release asphalt modified regenerant and preparation method thereof

An asphalt modification and rejuvenating agent technology, applied in building components, building thermal insulation materials, buildings, etc., can solve the problems of poor durability, inability to guarantee the effect of modified asphalt, and various types of asphalt rejuvenating agents, so as to enhance the anti-stripping resistance. performance, savings, and the effect of slowing down the aging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

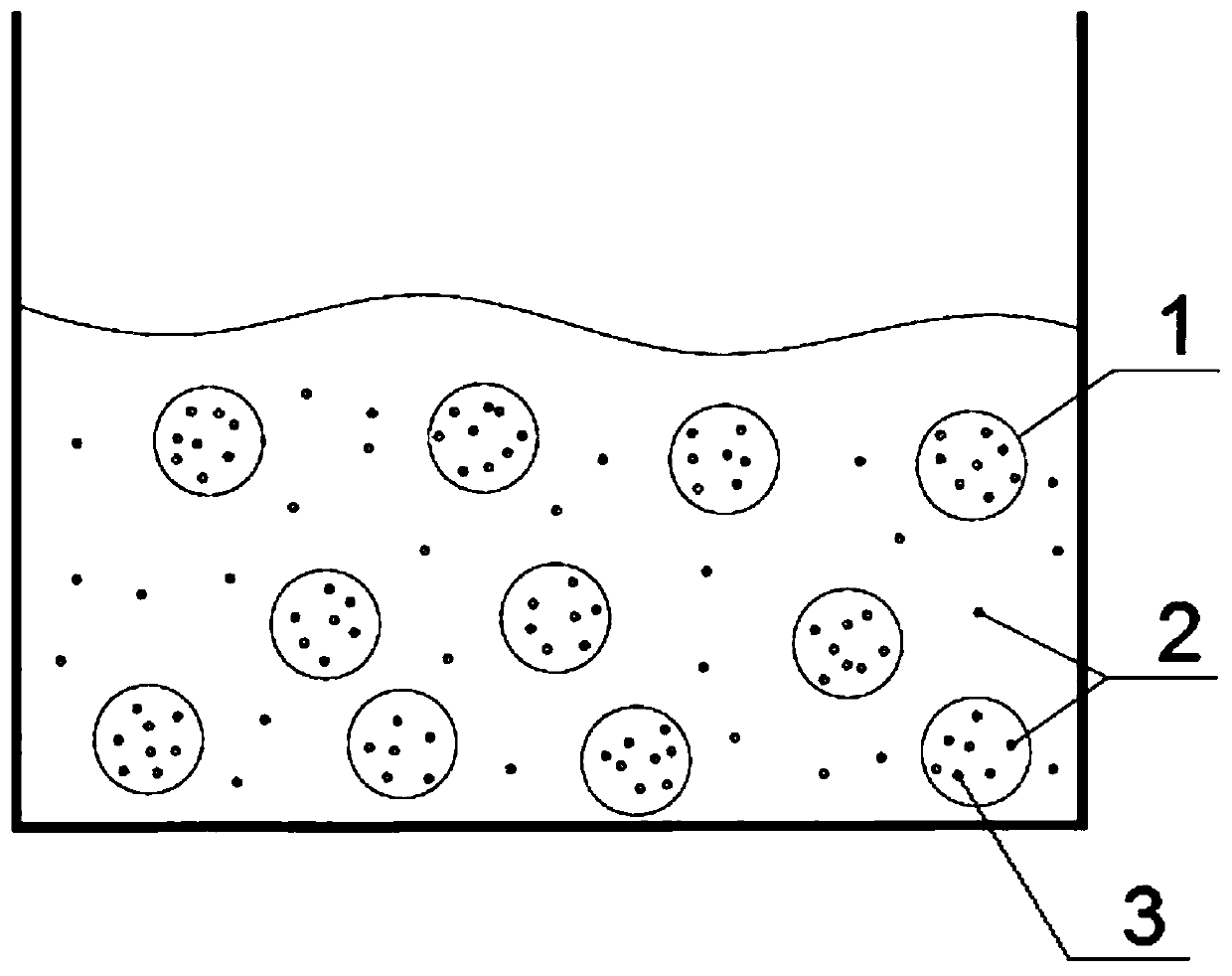

Image

Examples

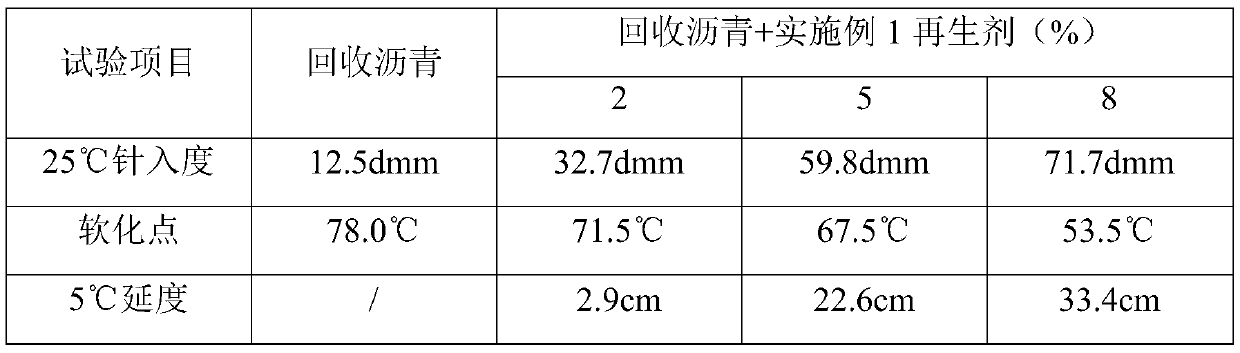

Embodiment 1

[0026] The slow-release asphalt modified rejuvenator consists of: 50 parts by mass of modified base oil, 30 parts by mass of base asphalt, 20 parts by mass of added oil, 3 parts by mass of plasticizer, 2 parts by mass of anti-aging agent, 2 parts by mass of modified agent, 5 parts by mass of capsule modifier.

[0027] Wherein the modified base oil consists of 95 parts by mass of waste oil and 5 parts by mass of modified additives. First, the waste oil is filtered to remove slag, flash dehydrated and sterilized. The modified additive is SPI and MD with a mass ratio of 2:3 as the wall material, and coated with sulfuric anhydride, vinylpyrrolidone, and 2-tert-butyl-p-cresol (the mass ratio of the three is 2:1:1) as Microcapsule A of the core material. Base asphalt is 110# asphalt. The added oil is composed of distillate oil and aromatic oil mixed uniformly at a mass ratio of 2:3. The plasticizer is epoxy soybean oil, and the anti-aging agent is tetrakis[β-(3,5-di-tert-butyl-4...

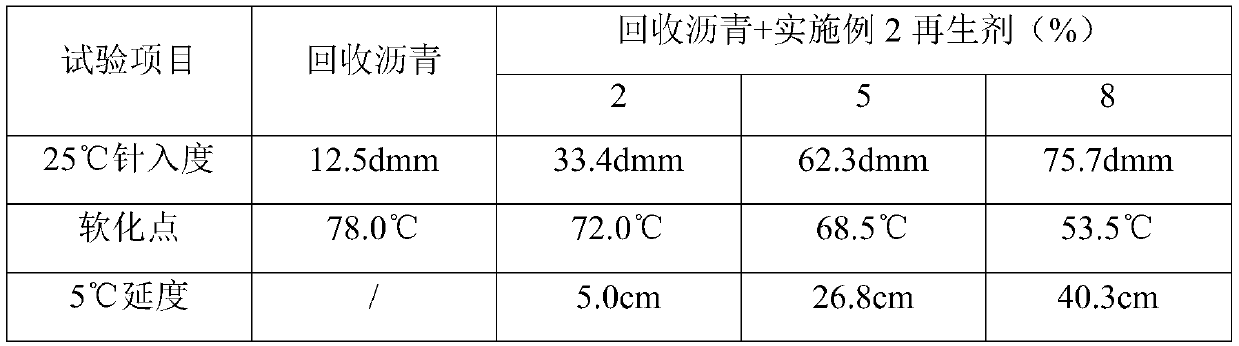

Embodiment 2

[0033] The slow-release asphalt modified rejuvenator consists of 55 parts by mass of modified base oil, 25 parts by mass of base asphalt, 25 parts by mass of added oil, 3 parts by mass of plasticizer, 2 parts by mass of anti-aging agent, and 2 parts by mass of modifier , 6 parts by mass of capsule modifier.

[0034] Wherein the modified base oil consists of 96 parts by mass of waste oil and 4 parts by mass of modified additives. First, the waste oil is filtered to remove slag, flash dehydrated and sterilized. The modified additive is microcapsule A with SPI and MD at a mass ratio of 1:1 as the wall material and coated with sulfuric anhydride, p-quaterphenyl, and phenol (the mass ratio of the three is 2:1:2) as the core material. The base asphalt is a combination of 90# asphalt and vegetable asphalt with a mass ratio of 7:3. The added oil is composed of extracted oil and aromatic oil mixed uniformly at a mass ratio of 2:3. The plasticizer is epoxy butyl furfurate, the antiag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com