System device for producing needle coke crude oil through catalytic slurry oil

A technology of catalytic oil slurry and system equipment, which is applied in the fields of hydrocarbon oil treatment products, petroleum industry, hydrocarbon oil treatment, etc. It can solve the problems of unutilized petroleum resources, abrasion of heating furnace burners, coking environment, etc., and achieve reduction of process energy consumption , improve the aroma, the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

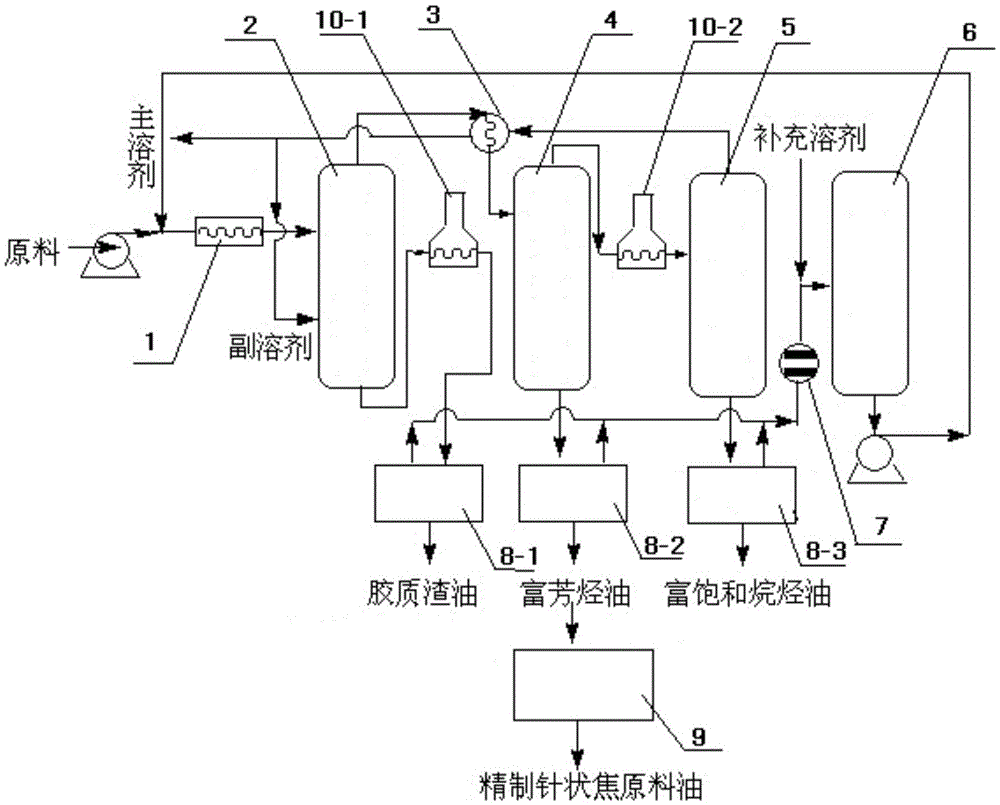

[0018] Such as figure 1 As shown, the catalytic oil slurry production needle coke raw material oil system device, the device mixer 1, the top of the catalytic oil slurry extraction tower 2, the top of the aromatic-rich oil separation tower 4, and the top of the alkane-rich oil extraction tower 5 are connected in sequence through pipelines , the bottom of the catalytic oil slurry extraction tower 2 is connected to the stripping tower A8-1, the bottom of the rich aromatic oil separation tower 4 is directly connected to the stripping tower B8-2, and the bottom of the rich alkane oil extraction tower 5 is connected to the stripping tower C8- 3 connections, the gas outlets of stripping tower A8-1, stripping tower B8-2, and stripping tower C8-3 are connected in sequence and then connected with condenser 7 and solvent tank 6, and the bottom of stripping tower B8-2 reacts with hydrogenation refining Device 9 is connected. A heat exchanger 3 is also provided between the catalytic oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com