Roller drying machine

The technology of rolling drying and rolling is applied in the field of tea processing devices, which can solve the problems of low aroma and easy gray color, and achieve the effects of promoting green color, good color and high aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

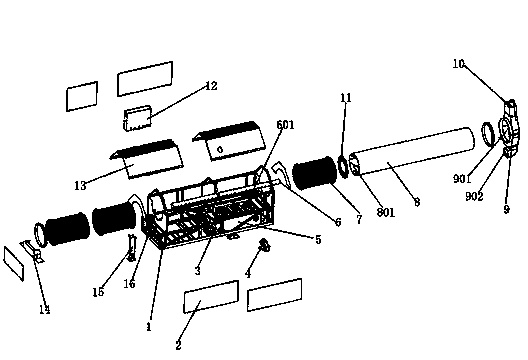

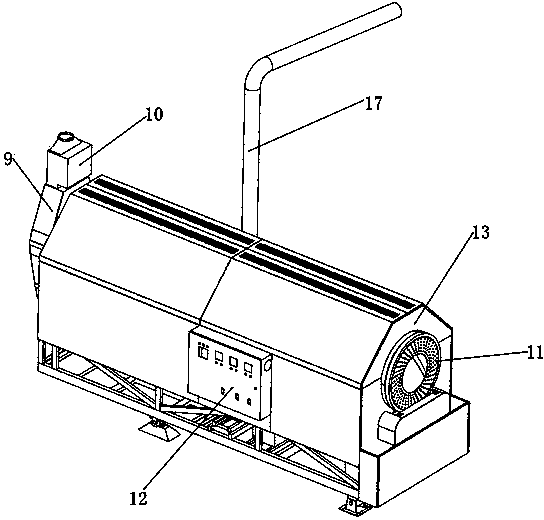

[0017] As shown in the figure, a tumble dryer includes a main frame 1 on which a closed structure is formed by fixed side plates 2 and a top plate 13 . The main frame 1 is provided with a drum 8 , and the inner wall of the drum 8 is provided with a spiral guide vane 801 , and the guide vane 801 helps the tea leaves to move evenly in the drum 8 . A heat source exchange chamber 5 is arranged below the drum 8, an axial flow fan 3 is arranged on one side of the heat source exchange chamber 5, a burner 4 is arranged on the heat source exchange chamber 5, and the heat source exchange chamber 5 is composed of a hot runner. The burner 4 heats to generate heat, and the air in the tumble dryer body exchanges heat with the heat source exchange chamber 5. After the exchange, the waste gas in the heat source exchange chamber 5 is discharged from the chimney 17, and the exchanged hot air is discharged under the action of the axial flow fan 3 for heating.

[0018] The drum 8 is covered with...

Embodiment 2

[0023] When the device of the present invention is used for operation, the drum temperature and the hot air temperature are set by controlling the operation of the electromagnetic heating jacket 7 and the hot air pipe 6 through the control of the electrical box 12, wherein the drum temperature is set to 85°C, and the hot air temperature is set to 125°C , and adjust the rotating speed of drum 8 to be 700rpm, and the wind speed to be 10m / s. After the temperature reaches the set value, the curly-shaped green tea in-process with a moisture content of 18% is put in from the feed end, and the in-process product advances with the guide vanes 801 in the cylinder of the drum 8, while rubbing against the cylinder wall to accept the pressure of the cylinder wall. The high heat evaporates the water, and the other side is wrapped by the high-temperature hot air input from 6 hot air pipes. The water is evaporated by the hot air, and finally the goal of dryness is achieved.

Embodiment 3

[0025] When the device of the present invention is used for operation, the drum temperature and the hot air temperature are set by controlling the operation of the electromagnetic heating jacket 7 and the hot air pipe 6 through the control of the electrical box 12, wherein the drum temperature is set to 95°C, and the hot air temperature is set to 115°C , and adjust the rotating speed of the drum to 700rpm and the wind speed to 10m / s. After the temperature reaches the set value, the curly-shaped green tea product in process with a moisture content of 13% is put in from the feed end, and the product in process advances with the guide vanes in the drum 8, while rubbing against the wall of the drum to receive the high heat of the wall While evaporating water, the other side is wrapped by high-temperature hot air input from 6 hot air pipes at the same time, and the water is evaporated through the hot air to finally achieve the goal of dryness.

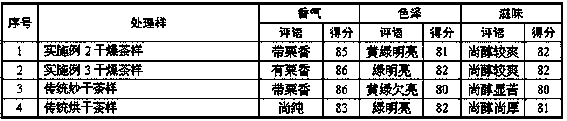

[0026] Table 1 Sensory evaluation re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com