Improved manufacture process of golden flower loose tea

A production process, golden flower technology, applied in the field of loose tea flower preparation technology, can solve the problems of medium chemical additive pollution, staying in the laboratory development stage, difficult to grasp the water content of tea base, etc., to achieve generally lush flowering , Shorten flowering cycle and ensure food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with embodiment the present invention is described in further detail:

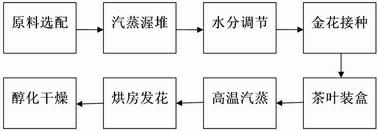

[0027] The technological process of the present invention is as follows: raw material selection→steaming and stacking→moisture adjustment→golden flower inoculation→tea packing→high-temperature steaming→flowering in a drying room→alcoholization and drying.

[0028] 1. Raw material selection: In order to achieve the same tea leaves, choose raw tea with similar shape and blend them into piles according to the ratio of ingredients;

[0029] 2. Steaming pile: the blended raw materials enter the turbine-propelled fermentation machine through the feed inlet, and steam for 2 minutes at a steam temperature of 130-180°C, then enter the pile from the feed port, mix well and form a pile. Keep the temperature at 60-70°C and stack for 4 hours;

[0030] 3. Moisture adjustment: After the heaping is finished, stir the tea leaves evenly, and use a moisture meter to measure the water content of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com