Method for preparing spinnable pitch from coal tar pitch

A technology for coal pitch and pitch, applied in the field of preparing spinnable pitch from coal pitch, can solve the problems of poor fluidity, gas entrainment loss, wide distribution of pitch softening point, etc., and achieves improved spinning performance, less pitch fume emission, and modification effect. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

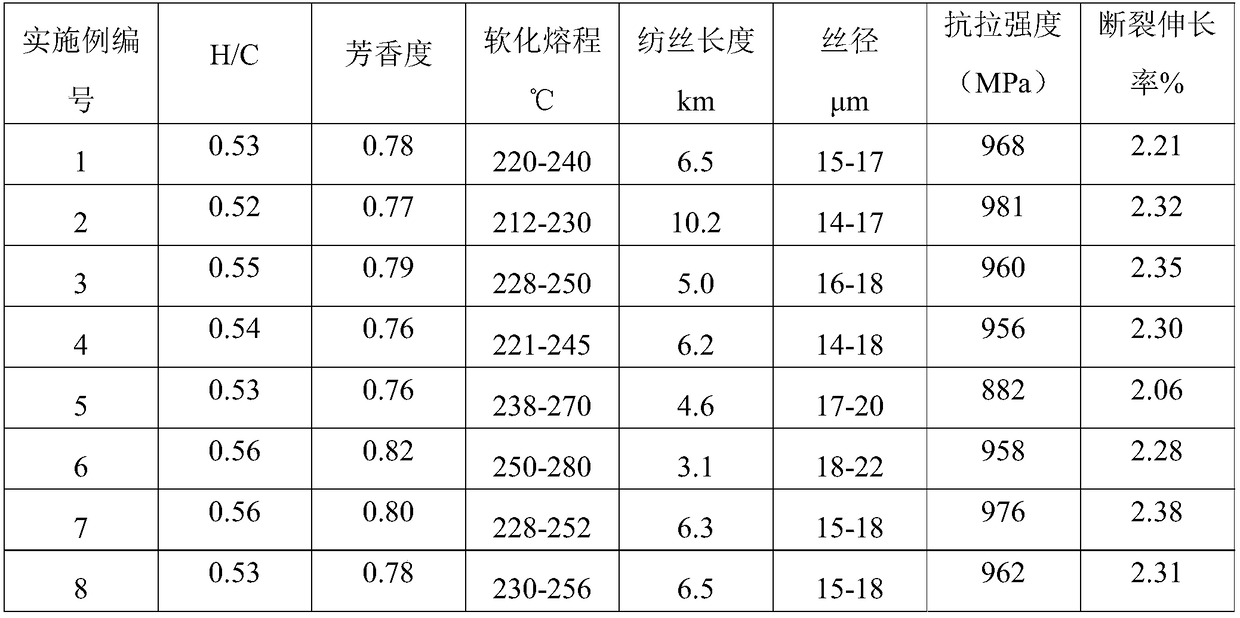

Examples

Embodiment 1

[0020] The preparation method of the present embodiment petrolatum modified asphalt comprises the following steps:

[0021] Step 1: Grind medium-low temperature coal tar pitch (ash content 0.2wt%, softening point: 70°C) to below 20 mesh, mix with tetrahydrofuran at a mass ratio of 1:4, extract and filter out the soluble components of medium-temperature coal tar pitch, and recover the solvent After tetrahydrofuran, refined pitch (ash content 0.03wt%, molecular weight distribution 200-350, softening point 72) is obtained; refined coal tar pitch and petrolatum are mixed in a weight ratio of 50:1.

[0022] Step 2: Put the mixed material described in Step 1 into the reactor, blow in 20 mL / min·g of nitrogen gas at normal pressure, and heat to 180° C. at a heating rate of 5° C. / min. Stop feeding nitrogen at 180°C and continue feeding air at a rate of 40mL / min·g, heat to 310°C at a heating rate of 5°C / min, stop feeding air after staying for 4 hours and cool to room temperature. Spinn...

Embodiment 2

[0024] The preparation method of the present embodiment petrolatum modified asphalt comprises the following steps:

[0025] Step 1: Grind medium-low temperature coal tar pitch (ash content 0.15wt%, softening point: 80°C) to below 20 mesh, mix with tetrahydrofuran at a mass ratio of 1:5, extract and filter out the soluble components of medium-temperature coal tar pitch, and recover the solvent Finally, refined pitch (ash content 0.02wt%, molecular weight distribution 210-350, softening point 83) is obtained; refined coal tar pitch and petrolatum are mixed in a weight ratio of 50:1.

[0026] Step 2. Put the mixed material described in Step 1 into the reactor, blow in 20 mL / min·g nitrogen gas to purge at normal pressure, and heat to 180° C. at a heating rate of 3° C. / min. Stop feeding nitrogen at 180°C and continue feeding air at a rate of 20mL / min·g, heat to 310°C at a heating rate of 6°C / min, stop feeding air after staying for 4 hours, and cool to room temperature. Spinning pi...

Embodiment 3

[0028] The preparation method of the present embodiment petrolatum modified asphalt comprises the following steps:

[0029] Step 1. Grind medium-low temperature coal tar pitch (ash content 0.1wt%, softening point: 90°C) to below 20 mesh, mix it with tetrahydrofuran at a mass ratio of 1:9, extract and filter out the soluble components of medium-temperature coal tar pitch, and recover the solvent Finally, refined pitch (ash content 0.01wt%, molecular weight distribution 240-350, softening point 90) is obtained; refined coal tar pitch and petrolatum are mixed in a weight ratio of 10:1.

[0030] Step 2: Put the mixed material described in Step 1 into the reactor, blow in 25 mL / min·g of nitrogen gas to purge at normal pressure, and heat to 210° C. at a heating rate of 4° C. / min. Stop feeding nitrogen at 210°C and continue feeding air at a rate of 45mL / min·g, heat to 320°C at a heating rate of 5°C / min, stop feeding air after staying for 4 hours and cool to room temperature. Spinnin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com