Simple process method of chestnut-flavor-type roasted green tea

A processing method and aroma technology, applied in the field of tea processing, can solve problems such as adverse effects on added value of products, and achieve the effects of excellent comprehensive quality, high aroma, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

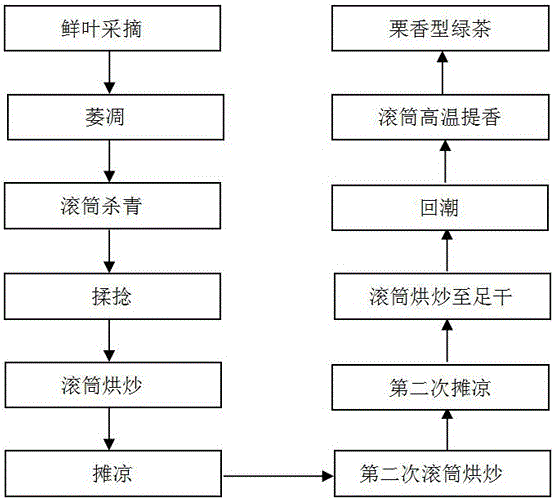

Image

Examples

Embodiment 1

[0030] A simple processing method for chestnut-flavored fried green tea, the specific steps are as follows:

[0031] (1) Picking fresh leaves: Picking fresh leaves of Longjing 43, the standard for fresh leaves is one bud and one leaf, one bud and two leaves, or one bud and three leaves, and the size is required to be uniform, free of broken pieces, diseases and insect pests;

[0032] (2) Withering: The fresh leaves are placed on the water screen in the airing room with a thickness of 5cm for 6 hours, and the water content of the fresh leaves is controlled at 70wt%; Ensure that the water loss of fresh leaves is even;

[0033] (3) Fixing: Use 6CWS-100 drum fixing machine with a speed of 20 rpm to fix the tea leaves after step (2) withering. The temperature is controlled at 250°C, the fixing time is 5 minutes, and the water content of the tea leaves is controlled to 45wt%. The amount of leaves per pot is 4kg. When the leaves lose their luster, the grassy smell disappears, the te...

Embodiment 2

[0044] A simple processing method for chestnut-flavored fried green tea, the specific steps are as follows:

[0045] (1) Picking fresh leaves: picking fresh leaves of Wuniuzao. The standard for fresh leaves is one bud and one leaf, one bud and two leaves, or one bud and three leaves.

[0046] (2) Withering: The fresh leaves are placed on the water screen in the airing room with a thickness of 8cm, and the water content of the fresh leaves is controlled at 80wt% for 8 hours; Ensure that the water loss of fresh leaves is even;

[0047] (3) Fixing: Use 6CWS-100 drum fixing machine with a speed of 25 rpm to fix the tea leaves after step (2) withering. The temperature is controlled at 280°C, the fixing time is 3 minutes, and the water content of the tea leaves is controlled to 55wt%. The amount of leaves per pot is 4kg. When the leaves lose their luster, the grassy smell disappears, the tender stems are broken continuously, and it is advisable to hold the leaves in hands; cool the...

Embodiment 3

[0058] A simple processing method for chestnut-flavored fried green tea, the specific steps are as follows:

[0059] (1) Picking fresh leaves: Picking fresh leaves of Meizhan, the standard for fresh leaves is one bud and one leaf, one bud and two leaves, or one bud and three leaves, and the size is required to be uniform and free from broken pieces, diseases and insect pests;

[0060] (2) Withering: the fresh leaves are placed on the water screen in the airing room with a thickness of 6cm, and the water content of the fresh leaves is controlled at 75wt% for 7 hours; Ensure that the water loss of fresh leaves is even;

[0061] (3) Fixing: Use 6CWS-100 drum fixing machine with a rotating speed of 22 rpm to fix the tea after withering in step (2). The temperature is controlled at 265°C, the fixing time is 4 minutes, and the water content of the tea is controlled at 50wt%. The amount of leaves per pot is 4kg. When the leaves lose their luster, the grassy smell disappears, the ten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com