Method for comprehensively utilizing chlorination tail gas in chlorination-process titanium dioxide powder production procedures

A production process, a technology for chlorinating tail gas, applied in chemical instruments and methods, chlorine/hydrogen chloride, preparation with chloride, etc., can solve the problems of waste of carbon resources, unreasonable utilization of combustion heat, and uneffective utilization, etc. Reduce emission pressure and production costs, improve resource utilization, and achieve the effect of effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

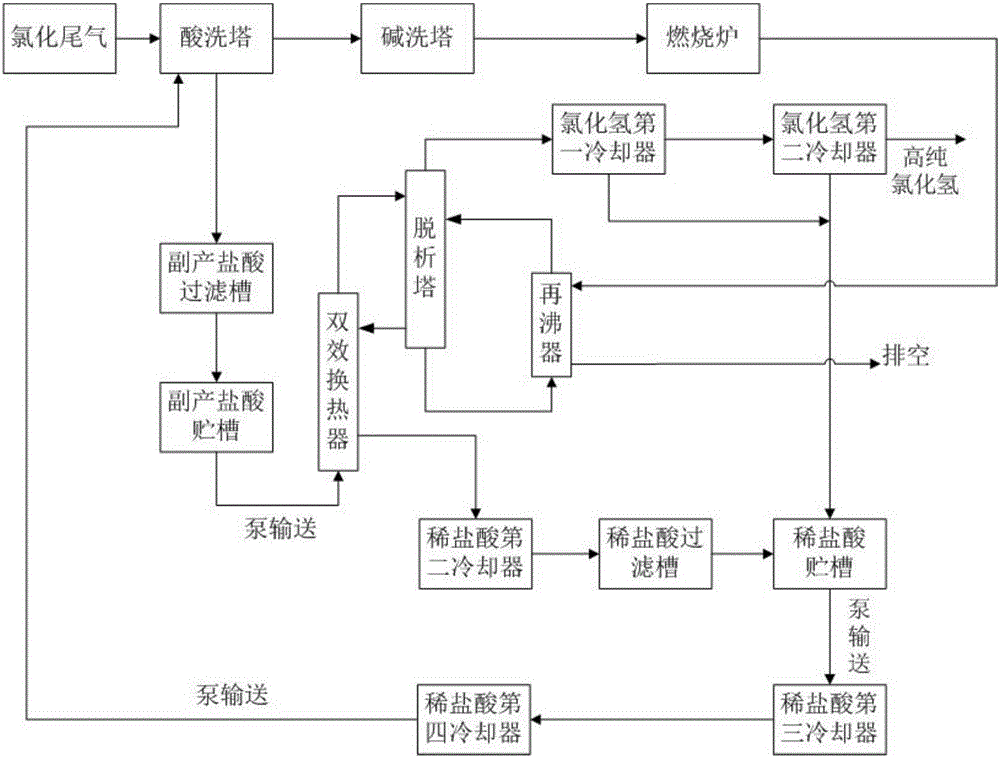

Embodiment 1

[0032] The chlorination tail gas produced in the production process of chlorination titanium dioxide is passed into the pickling tower to obtain by-product hydrochloric acid; the tail gas after pickling is passed into the alkali washing tower, and the tail gas after alkali washing enters the combustion furnace for combustion, and the combustion generates hot smoke The gas is mixed with air and cooled to about 250°C, then enters the reboiler to heat the hydrochloric acid in the desorption tower, and finally evacuates; the by-product hydrochloric acid obtained by pickling the chlorination tail gas is filtered through the by-product hydrochloric acid filter tank to obtain a concentration of about 25% The hydrochloric acid enters the by-product hydrochloric acid storage tank, the hydrochloric acid in the by-product hydrochloric acid storage tank is pumped to the double-effect heat exchanger for heat exchange, the temperature rises from 30°C to 70°C, and then enters the desorption to...

Embodiment 2

[0034] The chlorination tail gas produced in the production process of chlorination titanium dioxide is passed into the pickling tower to obtain by-product hydrochloric acid; the tail gas after pickling is passed into the alkali washing tower, and the tail gas after alkali washing enters the combustion furnace for combustion, and the combustion generates hot smoke The gas is mixed with air and cooled to about 225°C, then enters the reboiler to heat the hydrochloric acid in the desorption tower, and finally evacuates; the by-product hydrochloric acid obtained by pickling the chlorination tail gas is filtered through the by-product hydrochloric acid filter tank to obtain a concentration of about 28% The hydrochloric acid enters the by-product hydrochloric acid storage tank, the hydrochloric acid in the by-product hydrochloric acid storage tank is pumped to the double-effect heat exchanger for heat exchange, the temperature rises from 25°C to 65°C, and then enters the desorption to...

Embodiment 3

[0036] The chlorination tail gas produced in the production process of chlorination titanium dioxide is passed into the pickling tower to obtain by-product hydrochloric acid; the tail gas after pickling is passed into the alkali washing tower, and the tail gas after alkali washing enters the combustion furnace for combustion, and the combustion generates hot smoke The gas is mixed with air to cool to about 200°C, then enters the reboiler to heat the hydrochloric acid in the desorption tower, and finally evacuates; the by-product hydrochloric acid obtained by pickling the chlorination tail gas is filtered through the by-product hydrochloric acid filter tank to obtain a concentration of about 30% The hydrochloric acid enters the by-product hydrochloric acid storage tank, the hydrochloric acid in the by-product hydrochloric acid storage tank is pumped to the double-effect heat exchanger for heat exchange, the temperature rises from 20°C to 60°C, and then enters the desorption tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com