Solar central water heating system with heat accumulation function

A technology of solar heat collector and hot water system, which is applied in the field of concentrated solar hot water system with heat storage function, can solve the problems of vacuum glass tube bursting, shortened life, and aging of non-metallic seals, so as to reduce energy consumption, Reducing the size of the water tank and reducing the effect of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

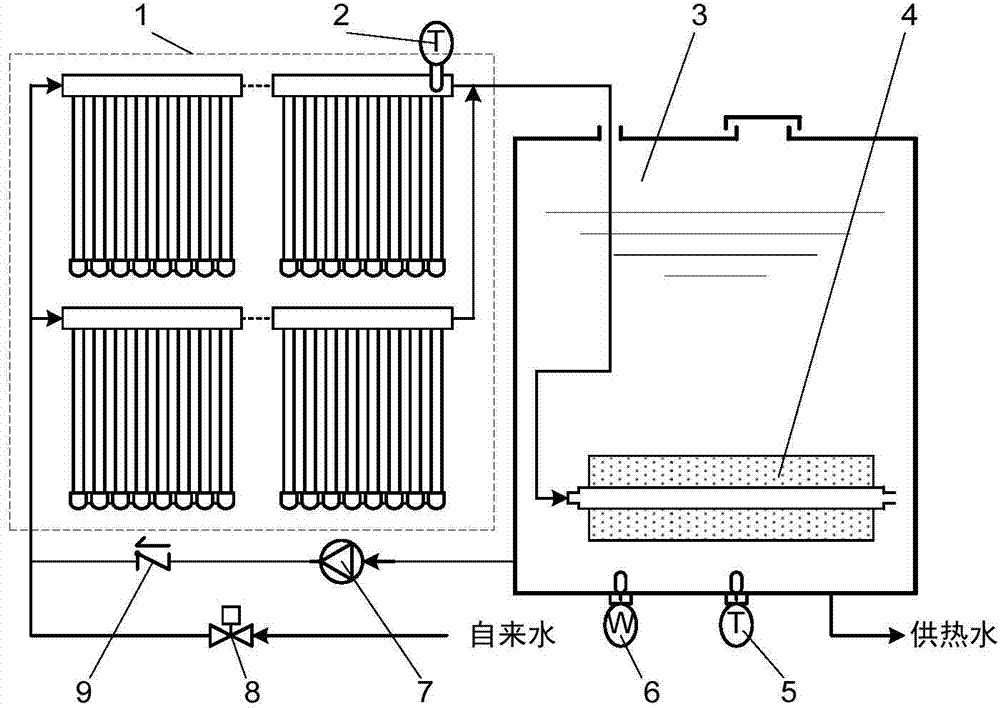

Embodiment 1

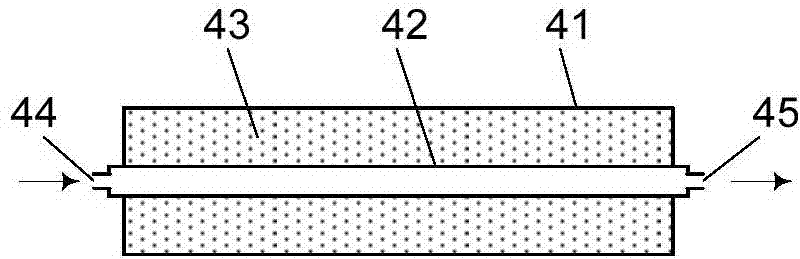

[0038] Such as figure 1 with image 3 As shown, the bottom of the water tank 3 is equipped with a heat accumulator 4, the heat accumulator 4 includes a heat accumulator shell 41 and a heat accumulator core pipe 42, and the heat accumulator shell 41 and the heat accumulator core pipe 42 form a jacket. The heat storage medium 43 is sealedly filled in the jacket, and the heat storage medium 43 is a liquid-solid phase change heat storage medium, and its phase change temperature T R Higher than the set system hot water supply temperature T S , and lower than 70°C, the phase transition temperature T of the heat storage medium 43 R =50~70°C, the preferred value is 55~60°C, the two ends of the heat accumulator core tube 42 are respectively the heat accumulator waterway inlet 44 and the heat accumulator waterway outlet 45, the heat accumulator waterway inlet 44 and the solar collector The outlet of the solar collector array 1 is connected, and the accumulator waterway outlet 45 is d...

Embodiment 2

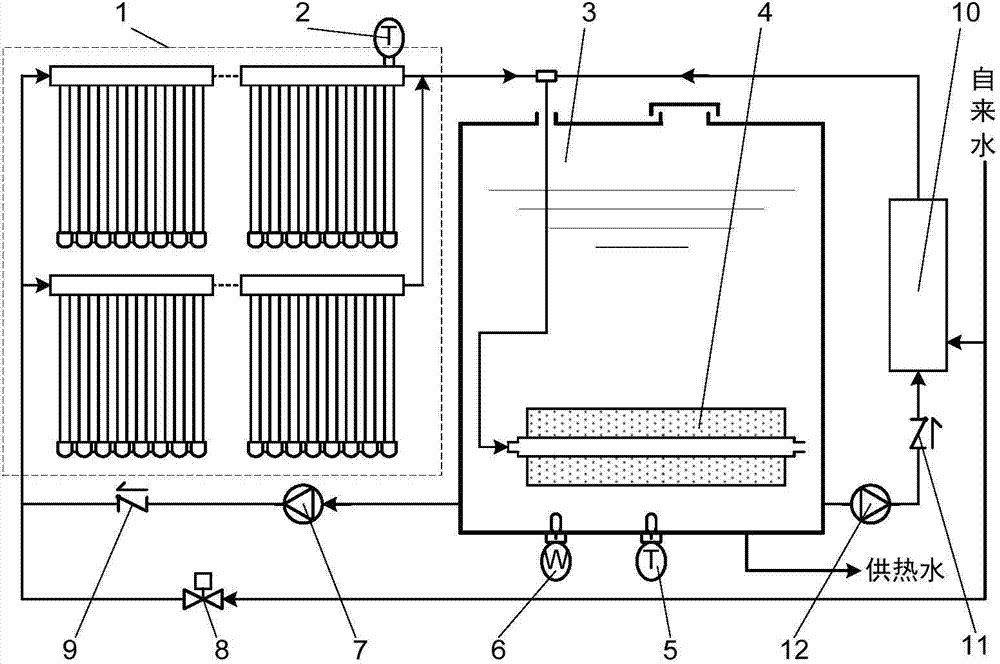

[0051] Such as figure 2 As shown, comparing this embodiment with Embodiment 1, an auxiliary heat source 10 (electric heater, heat pump, etc.) is added to the system. The lower part of the water tank 3 is connected, and the water outlet of the auxiliary heat source 10 is connected with the water inlet 44 of the accumulator; when the auxiliary heat source 10 (especially the heat pump) has the function of direct heat water production at the same time, its single direct heat water production inlet is also connected with Mains water connection. On the basis of the working method of embodiment 1, this embodiment relies on the auxiliary heat source 10 to supplement the production and supply of hot water under the condition of insufficient solar radiation and insufficient water production of the solar collector, so as to realize the all-weather hot water supply of the system; After the temperature of the water tank is reduced due to heat dissipation, the auxiliary heat source 10 als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com