Fused salt linear Fresnel heat collecting field anti-condensing system and method thereof

A molten salt and anti-condensation technology, which is applied to solar heating systems, solar collectors, and solar collector safety, can solve problems such as failure, increasing the volume of low-temperature molten salt tanks, and prolonging start-up time, so as to reduce the layout Slope requirements, saving engineering quantity and cost, and ensuring safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

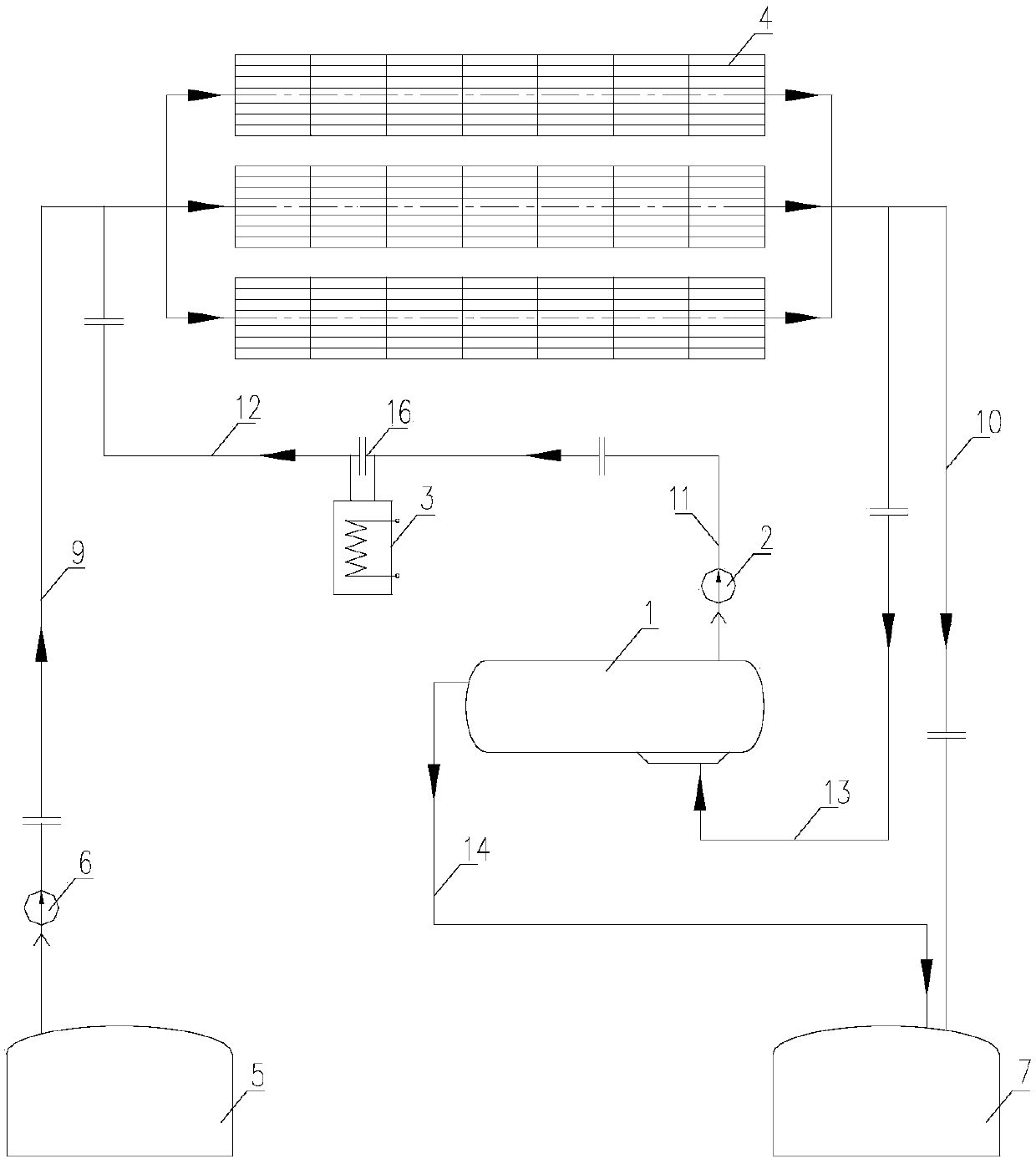

Embodiment 1

[0039] like figure 1 The shown anti-condensation system for a molten salt linear Fresnel heat collecting field includes a molten salt expansion tank 1 arranged at a high position, a linear Fresnel heat collecting field 4, a low temperature molten salt tank 5, a high temperature molten salt tank 7 and Molten salt heating unit 3;

[0040] The molten salt outlet of the low temperature molten salt tank 5 is communicated with the molten salt inlet of the linear Fresnel heat collecting field 4 through the low temperature molten salt pipeline 9, and the molten salt outlet of the linear Fresnel heat collecting field 4 is connected to the high temperature through the high temperature molten salt pipeline 10. The molten salt inlet of the molten salt tank 7 is communicated;

[0041] The molten salt outlet of the molten salt expansion tank 1 is communicated with the molten salt inlet of the molten salt heating unit 3 through the expansion tank outlet pipeline 11, and the molten salt outlet...

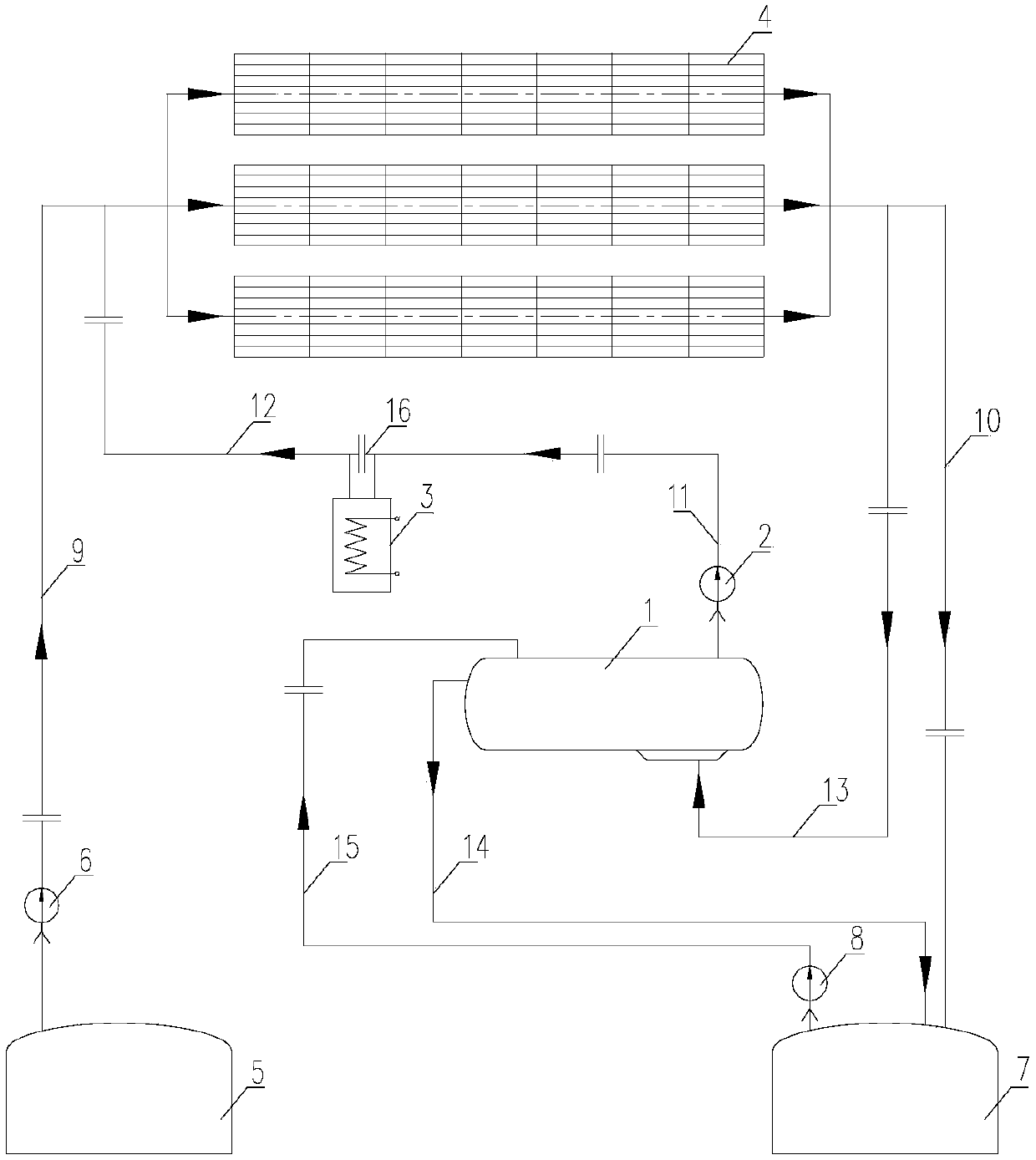

Embodiment 2

[0048] like figure 2 The shown anti-condensation system for a molten salt linear Fresnel heat collecting field includes a molten salt expansion tank 1 arranged at a high position, a linear Fresnel heat collecting field 4, a low temperature molten salt tank 5, a high temperature molten salt tank 7 and Molten salt heating unit 3;

[0049] The molten salt outlet of the low temperature molten salt tank 5 is communicated with the molten salt inlet of the linear Fresnel heat collecting field 4 through the low temperature molten salt pipeline 9, and the molten salt outlet of the linear Fresnel heat collecting field 4 is connected to the high temperature through the high temperature molten salt pipeline 10. The molten salt inlet of the molten salt tank 7 is communicated;

[0050] The molten salt outlet of the molten salt expansion tank 1 is communicated with the molten salt inlet of the molten salt heating unit 3 through the expansion tank outlet pipeline 11, and the molten salt out...

Embodiment 3

[0058] A kind of anti-condensation method of molten salt linear Fresnel heat collecting field realized by using the anti-condensation system of Example 1, in the initial stage of the shutdown of the linear Fresnel heat collecting field 4, that is, at night or under the condition of insufficient light, the linear Fresnel heat collecting field The Nell heat collecting field 4 cannot collect heat normally, resulting in the inability to heat the molten salt in the system. The waste heat of the molten salt in the heat collecting field is used for cyclic anti-condensation; when the molten salt in the system cannot achieve anti-condensation, the The molten salt heating unit 4 heats the molten salt so that the molten salt in the heat collecting field does not condense.

[0059] The method comprises the following steps: (a), utilizing the residual heat of the molten salt in the heat collecting field to perform cyclic anti-condensation; (b), compensating for anti-condensation by the molt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com