Swing arm continuous polishing machine

A technology of arm rings and racks, which is applied in the field of swing arm ring throwing machines, can solve the problems of limited size range, etc., and achieve the effects of increasing the processing range, improving market competitiveness, and improving resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

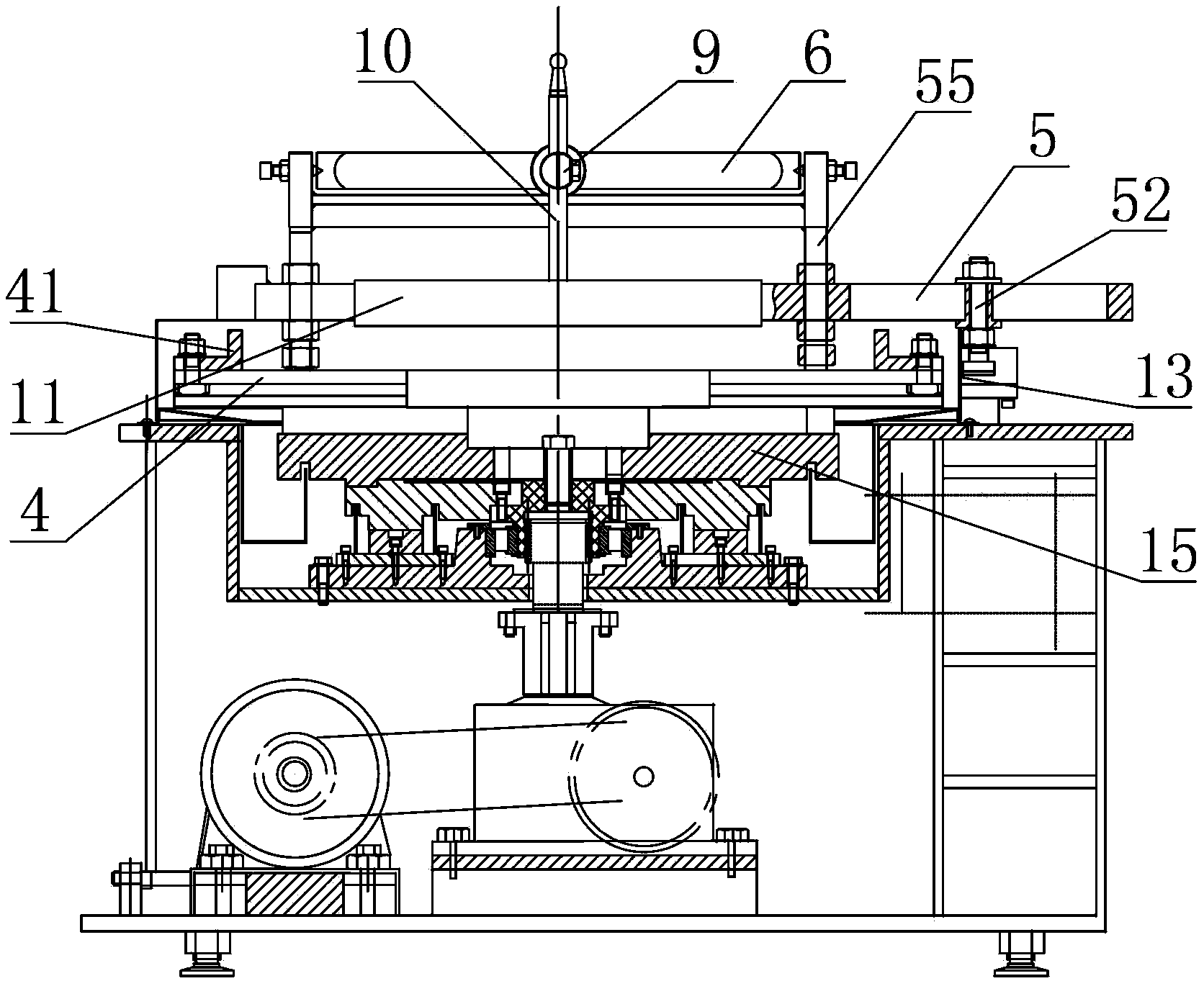

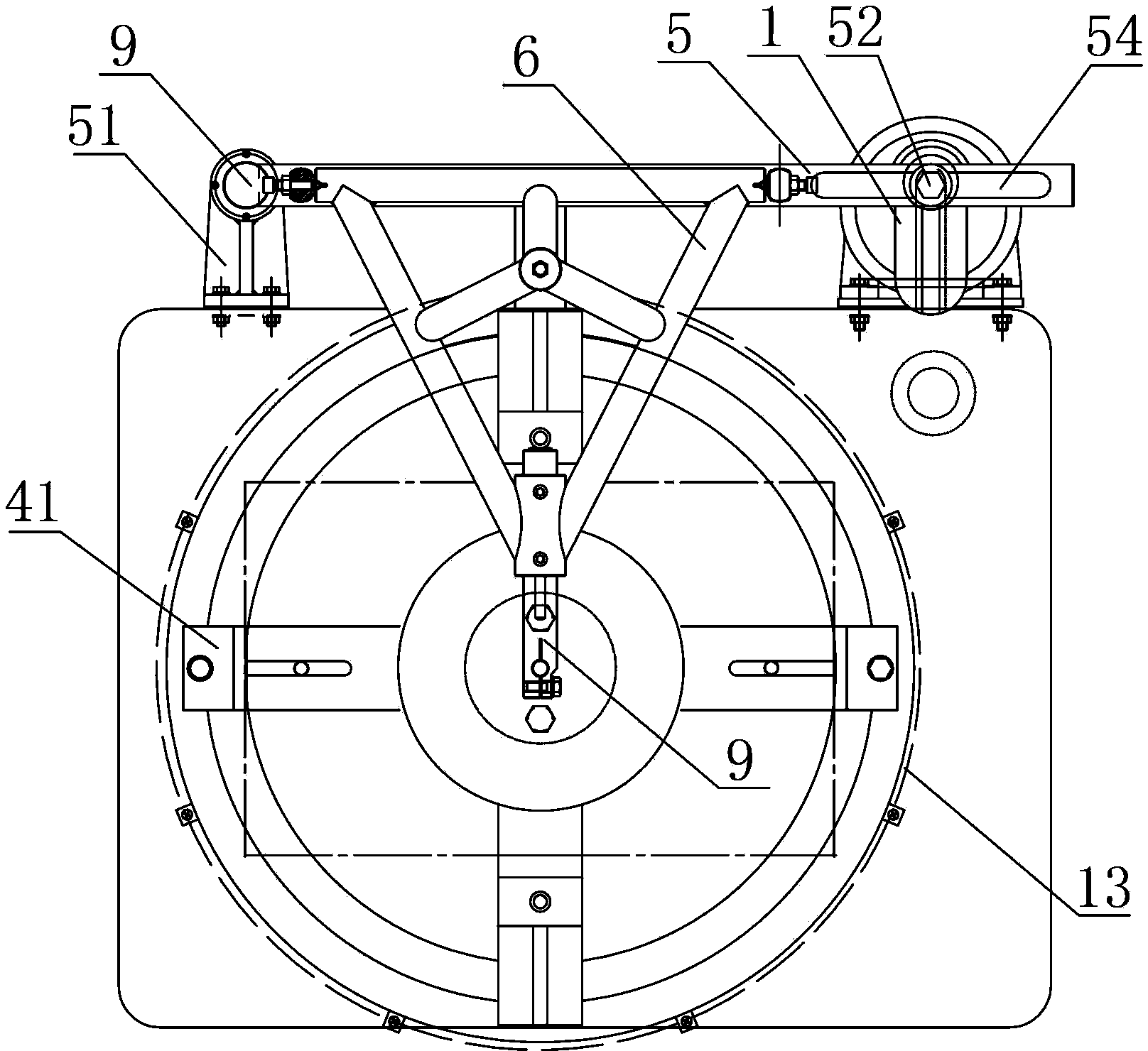

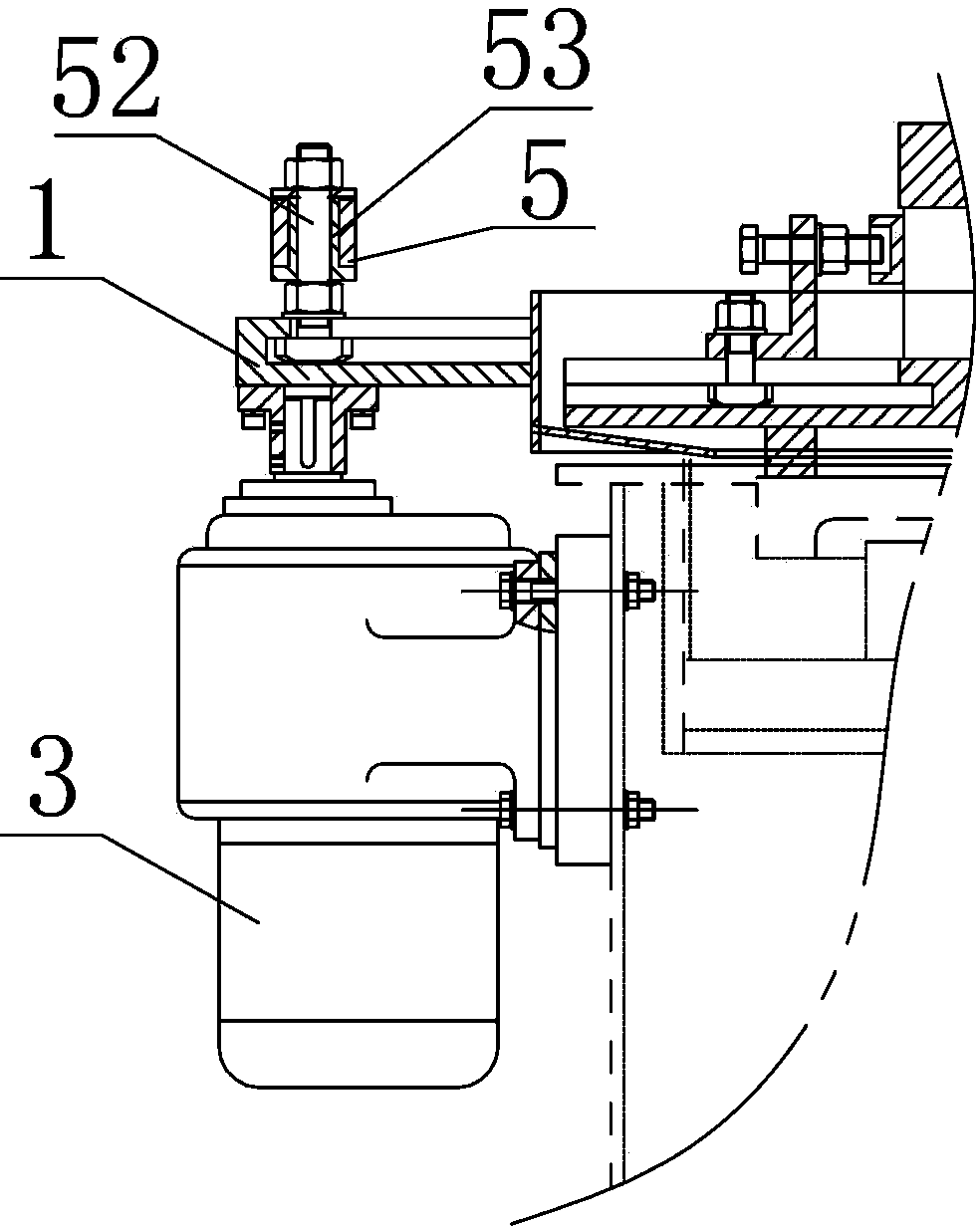

[0019] a kind of like Figure 1-3 The shown swing arm ring throwing machine includes a frame, a positioning chuck 4 that is horizontally arranged on the frame and used for positioning a workpiece, and a first grinding tool 11 that is arranged on the frame by a swing arm structure. The first grinding tool 11 is above the positioning chuck 4, wherein the swing arm structure includes a swing bar 5 with one end hinged on the frame, and the first grinding tool 11 is positioned on the swing bar 5 by a support arm , the other end of the swing rod 5 is driven to and fro by the rotation of an eccentric swing plate 1.

[0020] The present invention is a new design, and can also be improved on the basis of the existing ring throwing machine, mainly by adding a swing arm structure and a positioning chuck 4, so that the equipment can be restored to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com