Fully mechanized mining face end conveying and supporting integrated supporting device

A fully mechanized mining face and support device technology, applied to mining equipment, earthwork drilling, mine roof supports, etc., can solve problems such as difficulty in controlling the top plate at the end, squeezing the passage space, and the impact of continuous advancement. Anchoring and auxiliary push, slow down the chance of sliding, improve the effect of control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

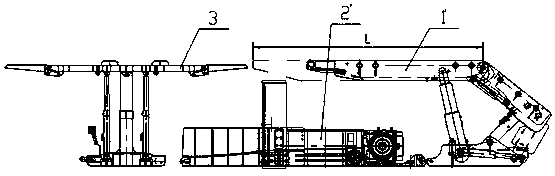

[0020] figure 1 It is the layout diagram of the support at the end of the transport trough in the existing fully mechanized mining face. It is composed of the hydraulic support 1' at the end of the long top beam and the hydraulic support 3 in advance. The transmission part of the unconstrained scraper conveyor 2' consists of The space protection formed by the top beam of the end hydraulic support 1', in order to realize full section support, the length of the top beam is L.

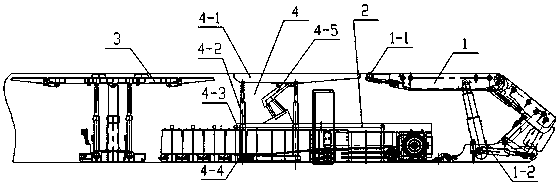

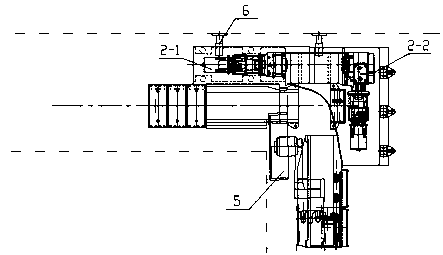

[0021] Such as Figure 2~4 As shown, the integrated support device 4 of the present invention is placed between the terminal hydraulic support 1 and the forward hydraulic support 3 along the groove. The terminal hydraulic support 1 adopts a telescopic roof beam structure, and the terminal hydraulic support 1 1', the length of the top beam is significantly shortened.

[0022] The integrated supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com