Preparation method of self-aligned double-layer X-ray zone plate

A technology of X-ray and zone plates, which is applied in the field of preparation of self-aligned double-layer X-ray zone plates, can solve problems such as the difficulty of hard X-ray zone plates, and achieve low cost, high diffraction efficiency, and consistent graphics good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: Utilize self-aligned exposure technology to make double-layer high aspect ratio X-ray zone plate:

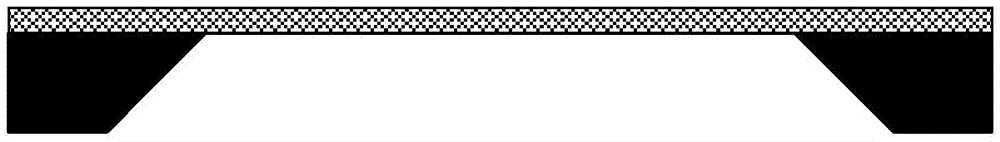

[0051] (1) Select a silicon nitride diaphragm base material with a thickness of 50nm. Deposit 5nm / 10nm Cr / Au on the substrate by physical vapor deposition as a conductive metal layer such as figure 1 shown.

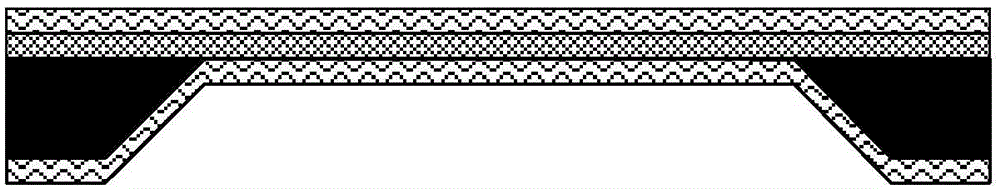

[0052] (2) Spin-coat a layer of HMDS on the front side of the substrate with a metal layer as an adhesion layer, then spin-coat a 500nm PMMA photoresist, and then do the same on the back; and bake at 180°C for 1 hour deal with. The result is as figure 2 shown.

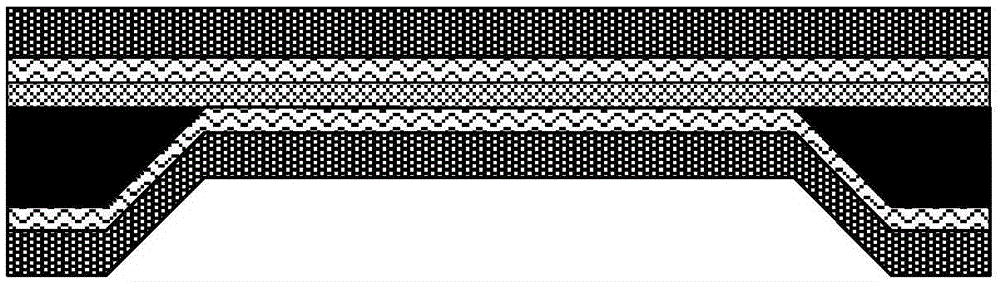

[0053] (3) Expose the sample under an electron beam exposure machine, develop the exposed sample with 1:3 MIBK and IPA for 1 minute, and develop at a temperature of 23°C; and wash in IPA for 30 seconds. The result is as image 3 shown.

[0054] (4) Electroplate Au on the surface of the developed sample using nano-electroplating technology. The electroplating conditions are: PH: 8.5, t...

Embodiment 2

[0057] Embodiment 2: Using self-aligned exposure technology to prepare a double-layer zone plate applied to hard X-rays:

[0058](1) A diaphragm of silicon nitride with a thickness of 50nm is selected as the base material. Deposit 5nm / 10nm Cr / Au on the substrate by physical vapor deposition as a conductive metal layer such as Figure 7 shown.

[0059] (2) Spin-coat a layer of HMDS on the front side of the substrate with a metal layer as an adhesion layer, then spin-coat a 500nm PMMA photoresist, and bake it at 180°C for 1 hour; then spin on the back of the sample Coat a layer of HMDS as an adhesion layer, spin-coat 500nm VUIII photoresist, and bake at 130°C for 1 minute. The result is as Figure 8 shown.

[0060] (3) Expose the sample under an electron beam exposure machine; after exposure, bake the sample at 130°C for 90s, develop it with an alkaline developer for 1 minute, wash it with deionized water and blow it dry with nitrogen before using it for 1 :3 (volume rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com