Blocky rubber continuous mixing method and device

A technology of block rubber and connecting equipment, applied in the field of continuous mixing of block rubber, can solve the problems of large investment in production equipment, complicated auxiliary equipment, and many processing procedures, achieve less auxiliary equipment, and avoid rubber stagnation and mixing. high quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Description with reference to the accompanying drawings.

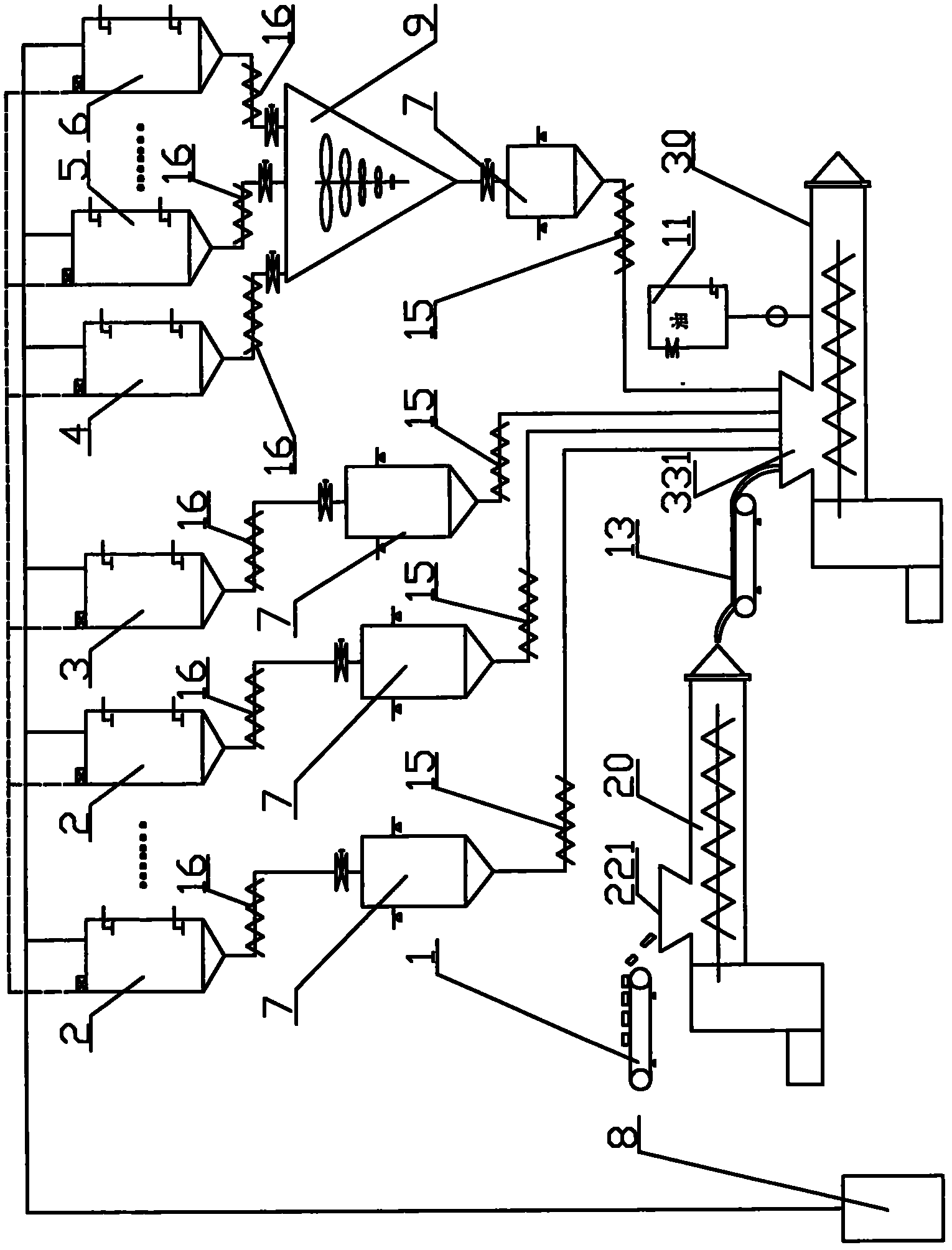

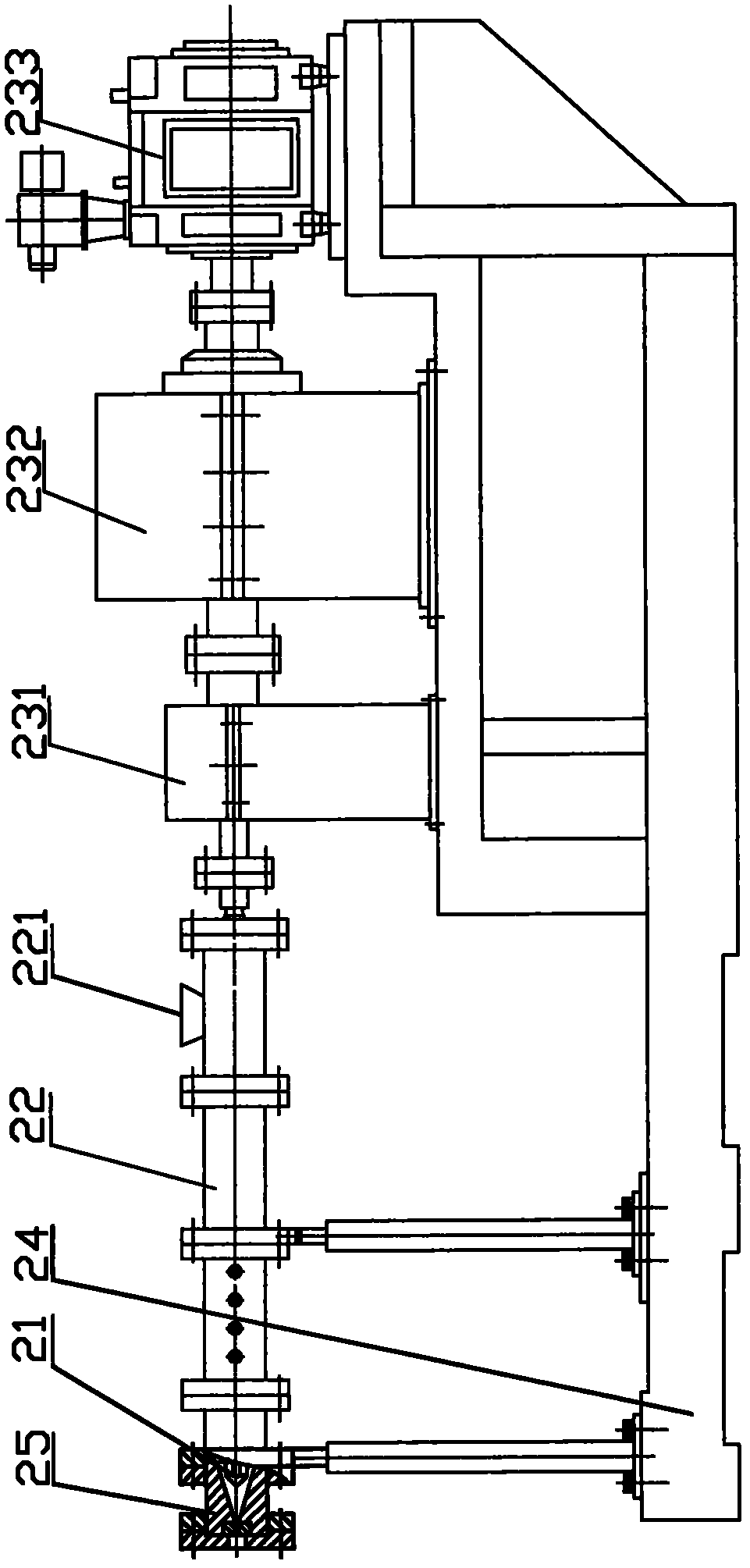

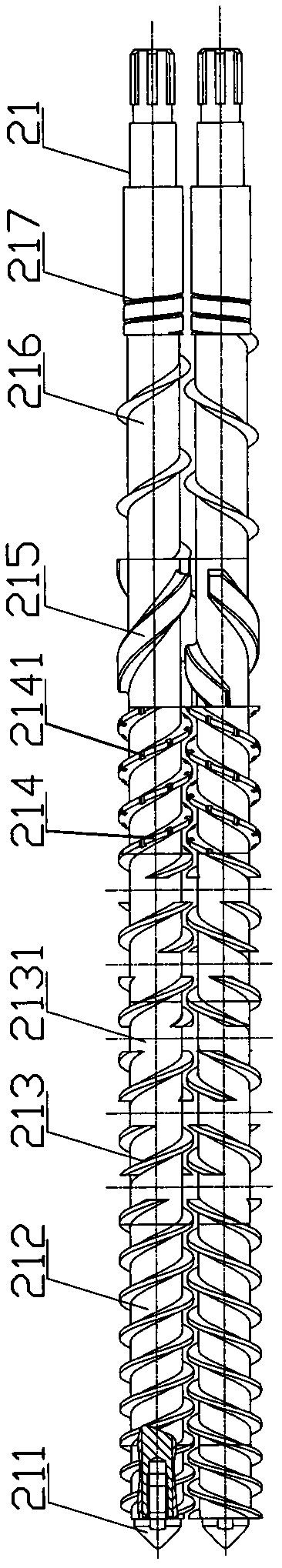

[0046] exist figure 1 In the shown embodiment of the continuous mixing of block rubber of the present invention, the raw rubber conveying device 1 feeds the block rubber to the plasticating feeding section of the plasticating rotor 21 of the block rubber continuous plasticating device 20 through the plasticating feeding port 221 216, see figure 2 and image 3 . The bulk rubber continuous plasticating device 20 continuously plasticizes the bulk rubber raw material, and extrudes the plasticized rubber film. The plasticized rubber film is input into the rubber continuous mixing device 30 through the rubber feeding control device. The metering pump of the oiling device 11 is used to add oil to the rubber continuous mixing device 30 , and the second half of the mixing barrel 33 is connected to the oiling device 11 . The solid compounding agent is fed into the rubber continuous mixing device 30 through the compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com