Preparation purification method of germanium tetrachloride for optical fiber

A technology of germanium tetrachloride and a purification method, applied in the chemical industry, can solve the problems of low production efficiency, reduction of the total amount of GeCl4, etc., and achieve the effects of high production efficiency, easy process and stable process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

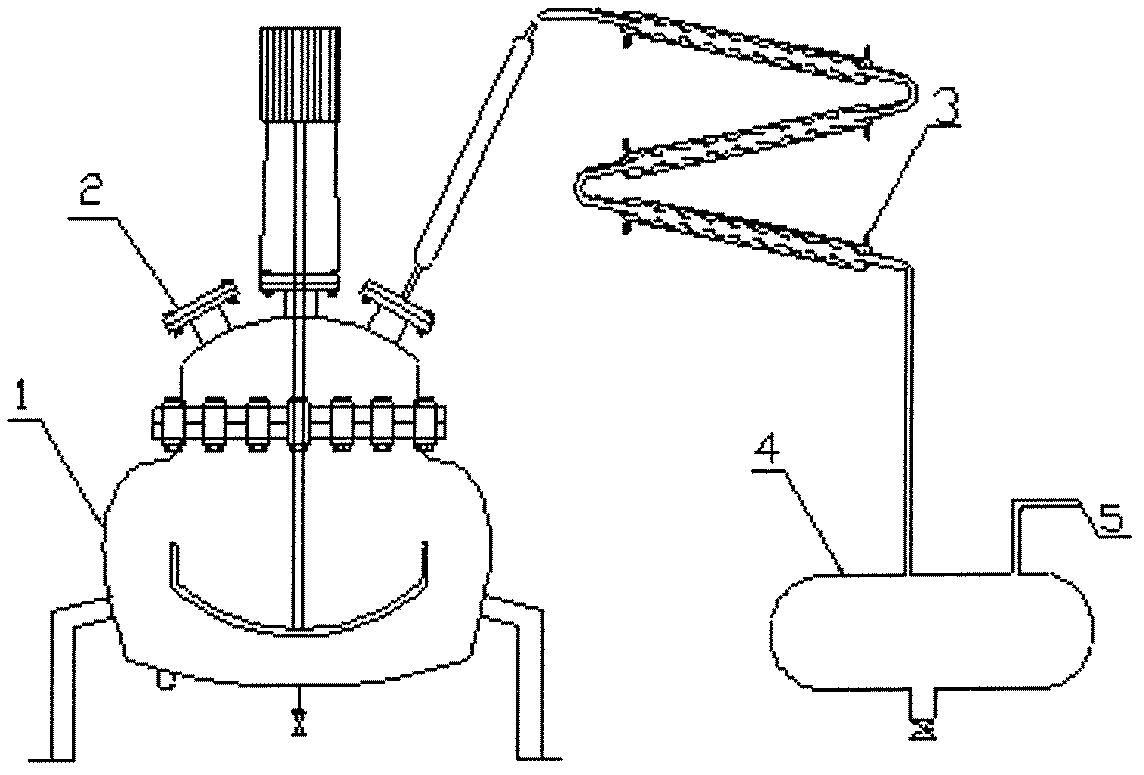

[0024] 1. Chlorination distillation:

[0025] In a 500L acid-resistant enamel distillation kettle, first add 35Kg of ferric chloride, then add 60Kg of germanium concentrate, close the solid feed port, add 400L HCl and 15L H 2 SO 4 . Set the kettle temperature of the chlorination enamel kettle at 60-120°C, energize and heat up and stir. When there is no more GeCl in the feed pipe 4 When flowing out, stop the distillation. See the diagram of the chlorination reaction device figure 1 .

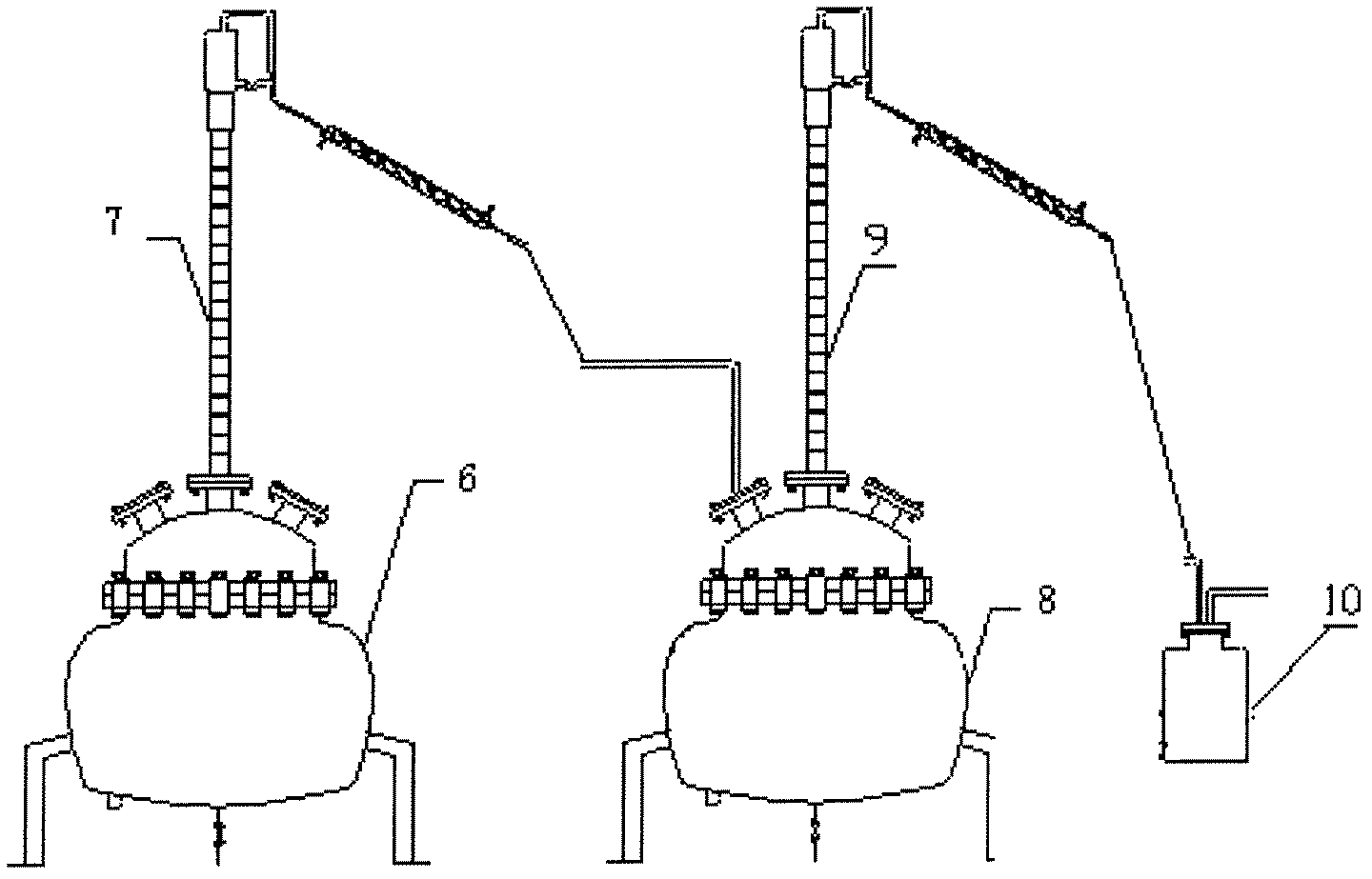

[0026] 2. Double steam distillation:

[0027] Add 25L of analytically pure hydrochloric acid to the 50L primary double-steaming reactor, add 800g of manganese dioxide, then add 18L of germanium tetrachloride, add 25L of concentrated hydrochloric acid to the 50L double-steaming reactor, add 500g of manganese dioxide, Open the feed valve of the double steaming once to increase the temperature. And the heating temperature setting range is 60-150℃, and the kettle temperature is controlled at 30-110℃. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com