Silicon-carrying microsphere, copper net for separating oil from water and preparation method thereof

A technology of silicon microspheres and microspheres, which is applied in the preparation of microspheres, microcapsule preparations, and separation of immiscible liquids, etc., can solve the problems of high price, little research on superhydrophobic coatings, and limited application of superhydrophobic materials, etc. The effect of uniform particle size, strong hydrophobicity and convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

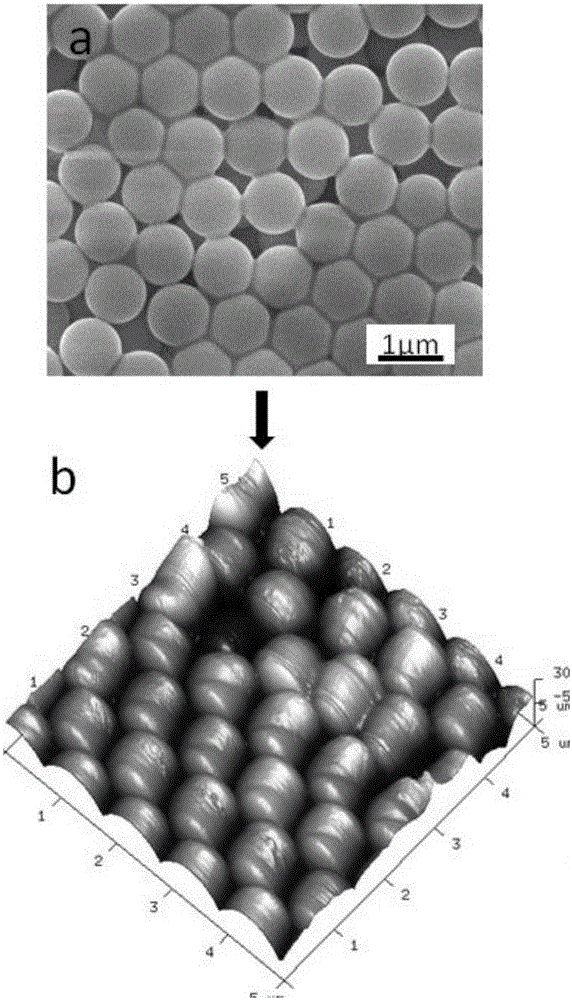

[0022] A preparation method of silicon-loaded microspheres, comprising the steps of:

[0023] Preparation steps of polymer microspheres: adding polymer monomers, initiators, dispersants and crosslinking agents into ethanol / water mixed solution to prepare polymer microspheres, blowing nitrogen gas for 25-35min, and then heating at 70-75°C Oil bath reaction, after the reaction, disperse and centrifuge with water and ethanol for 2-5 times respectively.

[0024] Adding polymer monomers, initiators, dispersants and cross-linking agents to the ethanol / water mixed solution is beneficial to the mixing of raw materials, passing nitrogen gas to form a nitrogen protection, which is beneficial to the formation of polymer microspheres, 70-75 ° C The oil bath reaction accelerates the formation of microspheres.

[0025] Further, in a preferred embodiment of the present invention, the polymer monomers for preparing polymer microspheres include styrene, methyl methacrylate, ethyl methacrylate...

Embodiment 1

[0038] A preparation method of silicon-loaded microspheres, comprising the steps of:

[0039] Preparation steps of polymer microspheres: (1) The preparation of the first polymer microspheres will account for 5% monomer styrene, methyl methacrylate and ethyl methacrylate in the mass of the total reaction system; % initiator azobisisobutyronitrile, azobisisoheptanonitrile; relative to monomer mass 1% crosslinking agent divinylbenzene, diethylene glycol diacrylate, triethylene glycol diacrylate; And 10% dispersant polyvinylpyrrolidone relative to the mass of the monomer; add it to the ethanol / water mixed solution with a volume fraction of 20%, stir evenly, feed nitrogen for 25min, and then react in an oil bath at 70°C for 10h; react After the end, disperse and centrifuge twice with water and ethanol respectively to obtain the first micron-sized polymer microspheres;

[0040] (2) The preparation of the second polymer microspheres will account for 5% of the total reaction system m...

Embodiment 2

[0044] A preparation method of silicon-loaded microspheres, comprising the steps of:

[0045] Polymer microsphere preparation steps: (1) preparation of the first polymer microsphere, will account for 7% monomer styrene of total reaction system mass; Relative to the initiator azobisisoheptanonitrile of 1.5% of monomer mass; 1.5% of the cross-linking agent based on monomer mass includes divinylbenzene, diethylene glycol diacrylate, triethylene glycol diacrylate, polyethylene glycol diacrylate, dipropylene glycol diacrylate, tripropylene glycol Diacrylate, 1,4-Butanediol Diacrylate, 1,6 Hexanediol Diacrylate, Neopentyl Glycol Diacrylate, 2(Propoxylated) Neopentyl Glycol Diacrylate, Ethoxylated Bisphenol A diacrylate, (ethoxy) bisphenol fluorene diacrylate, 6 (ethoxy) bisphenol fluorene diacrylate, tricyclodecane dimethanol diacrylate; and a dispersion of 12% relative to the monomer mass Add polyvinylpyrrolidone; add it to the mixed solution of ethanol / water with a volume fractio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com