Polyester composite material capable of being simultaneously applied to NMT technology and LDS technology and preparation method thereof

A polyester composite material and process technology, applied in the field of polyester composite materials, can solve problems such as complicated preparation process, and achieve the effect of simple and easy method, low cost, and suitable for large-scale production and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

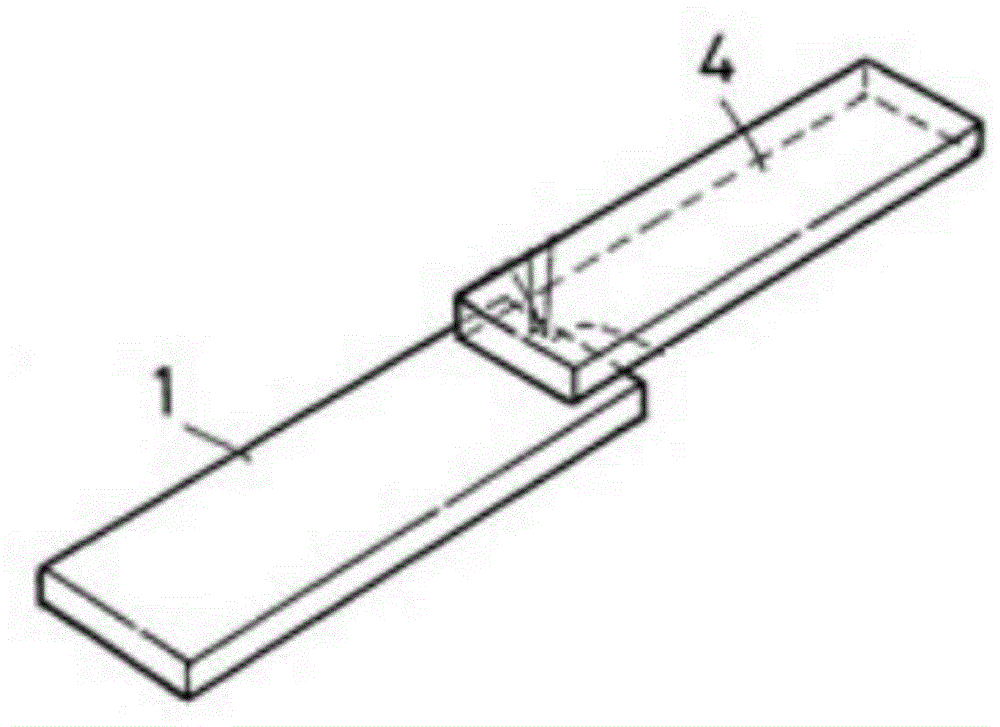

Image

Examples

Embodiment 1

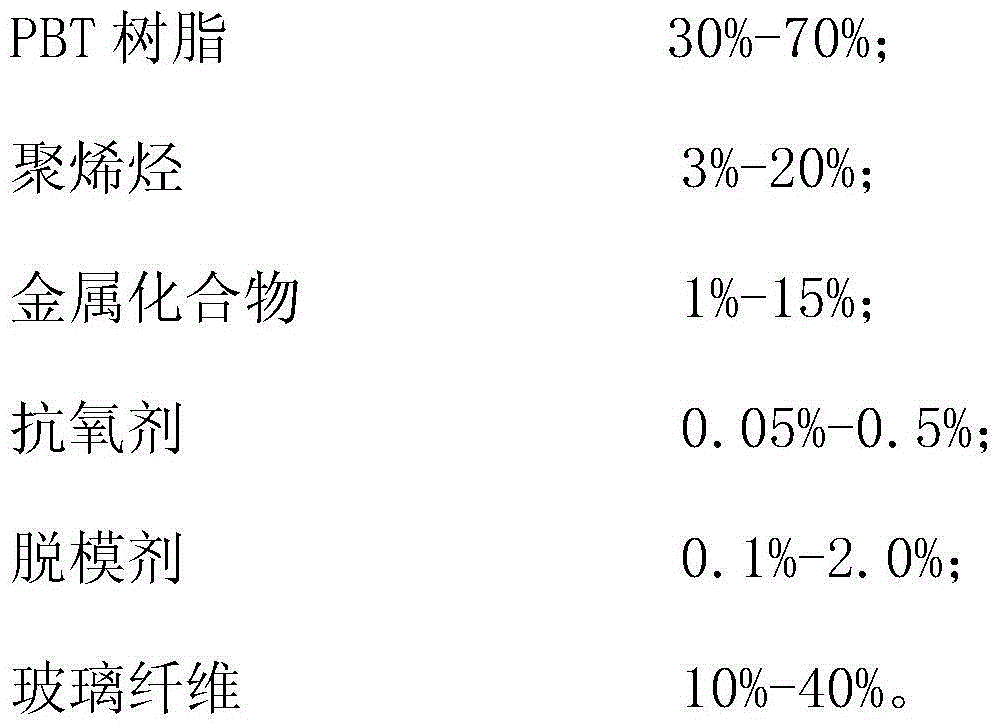

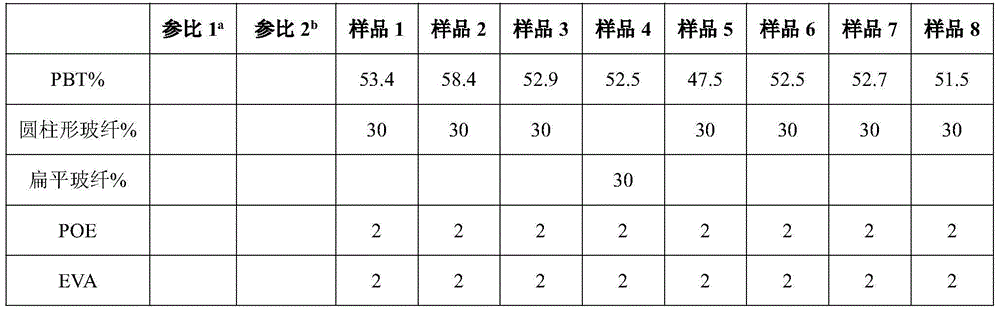

[0027] After mixing each component in a mixer according to the weight ratio shown in Table 1, use a twin-screw extruder to granulate, and the granulation temperature is between 220°C and 250°C. The obtained particles were processed by injection molding according to the standards and methods described in the instructions, and the binding force and PI value were tested. The test results are shown in Table 1.

[0028] Table 1

[0029]

[0030]

[0031] a. Reference 1 is NMT material 1101G of Toray Corporation of Japan

[0032] b. Reference 2 is Mitsubishi LDS material 3730

[0033] Wherein EVA is ethylene-vinyl acetate copolymer.

[0034] From the properties of the reference materials in Table 1, it can be seen that the NMT and LDS products currently on the market cannot meet the requirements of the two processes at the same time. However, all samples in Table 1 have both NMT binding ability and LDS activity, and the NMT binding ability and LDS activity of most samples ...

Embodiment 2

[0036] After mixing each component in a mixer according to the weight ratio shown in Table 2, use a twin-screw extruder to granulate, and the granulation temperature is between 220 degrees Celsius and 250 degrees Celsius. The obtained particles were processed by injection molding according to the standards and methods described in the instructions, and the binding force and PI value were tested. The test results are shown in Table 2.

[0037] Table 2

[0038]

[0039]

[0040] a. Reference 1 is NMT material 1101G of Toray Corporation of Japan

[0041] b. Reference 2 is Mitsubishi LDS material 3730

[0042] Wherein EVA is ethylene-vinyl acetate copolymer.

[0043] In Example 2, the influence of different other polyester resins on the NMT and LDS properties of the material was investigated. It can be seen from the data that the addition of other polyester resins can significantly improve the NMT binding force of the material, and at the same time, it has almost no nega...

Embodiment 3

[0045] After mixing each component in a mixer according to the weight ratio shown in Table 2, use a twin-screw extruder to granulate, and the granulation temperature is between 220 degrees Celsius and 250 degrees Celsius. The obtained particles were processed by injection molding according to the standards and methods described in the instructions, and the binding force and PI value were tested. The test results are shown in Table 3.

[0046]

[0047]

[0048] a. Reference 1 is NMT material 1101G of Toray Corporation of Japan

[0049] b. Reference 2 is Mitsubishi LDS material 3730

[0050] Wherein EVA is ethylene-vinyl acetate copolymer.

[0051] In Example 3, the effects of different glass fiber contents and different inorganic minerals on the binding force of NMT and the PI value of LDS activity were investigated. It can be seen from the data in Table 3 that the inorganic minerals used in the experiment can significantly increase the PI value of the polyester composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com