Method for preparing boron nitride nanometer ring and tube

A technology of nanotubes and nanorings, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of high cost and low yield, and achieve the effects of low cost, less environmental pollution and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: the preparation of boron nitride nano ring

[0023] The raw material for preparing boron nitride nanorings is H 3 BO 3 , Li 3 N and S.

[0024] First 0.31g H 3 BO 3 , 0.17g Li 3 N and 0.16gS were ground and mixed evenly, pressed into tablets at 20MPa, and then put into a quartz tube. After vacuumizing the quartz tube, it was filled with 1 atm of Ar gas. After heating the quartz tube to 600°C for 1 hour and then cooling down to room temperature naturally, the product is first treated with carbon disulfide to remove the sulfur contained in the product, then washed with deionized water and suction filtered 3-5 times. The product thus obtained is dried at 80° C. to obtain boron nitride nanorings.

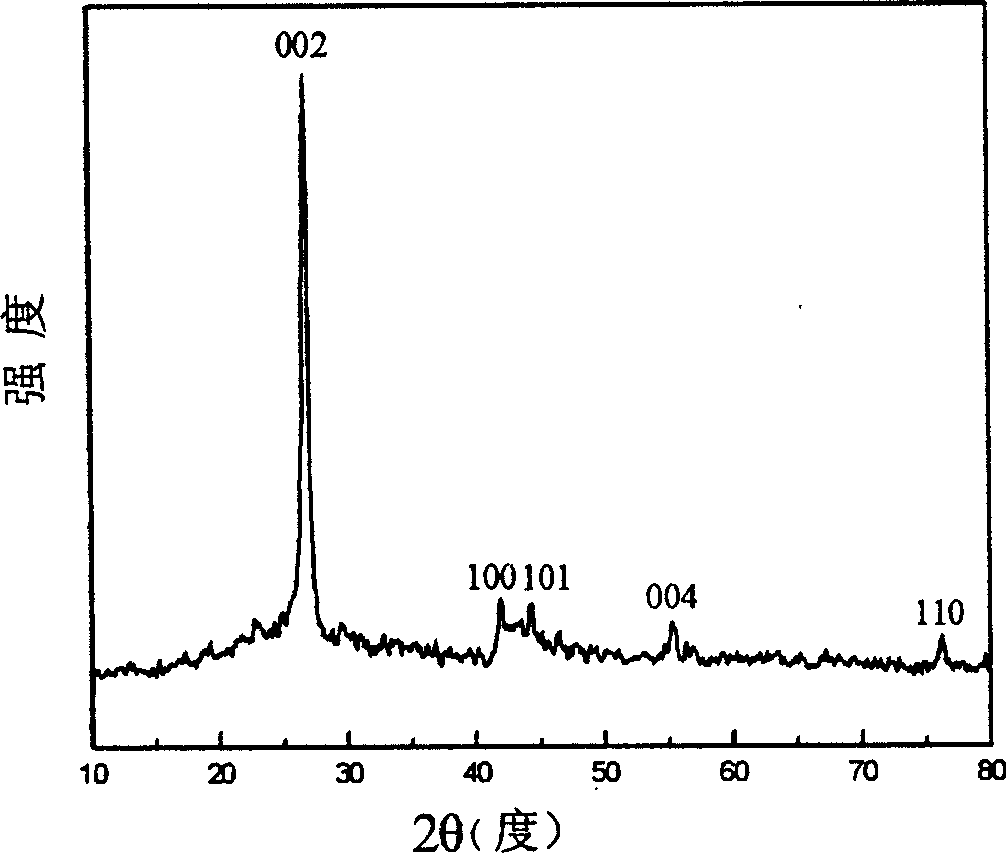

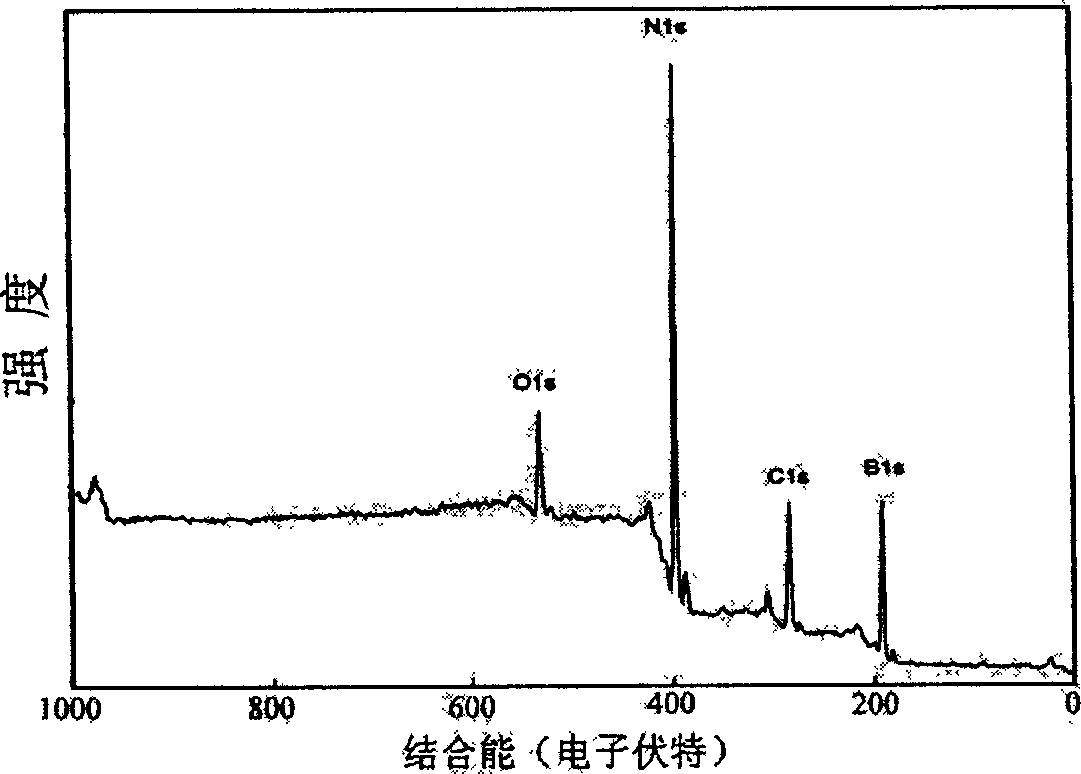

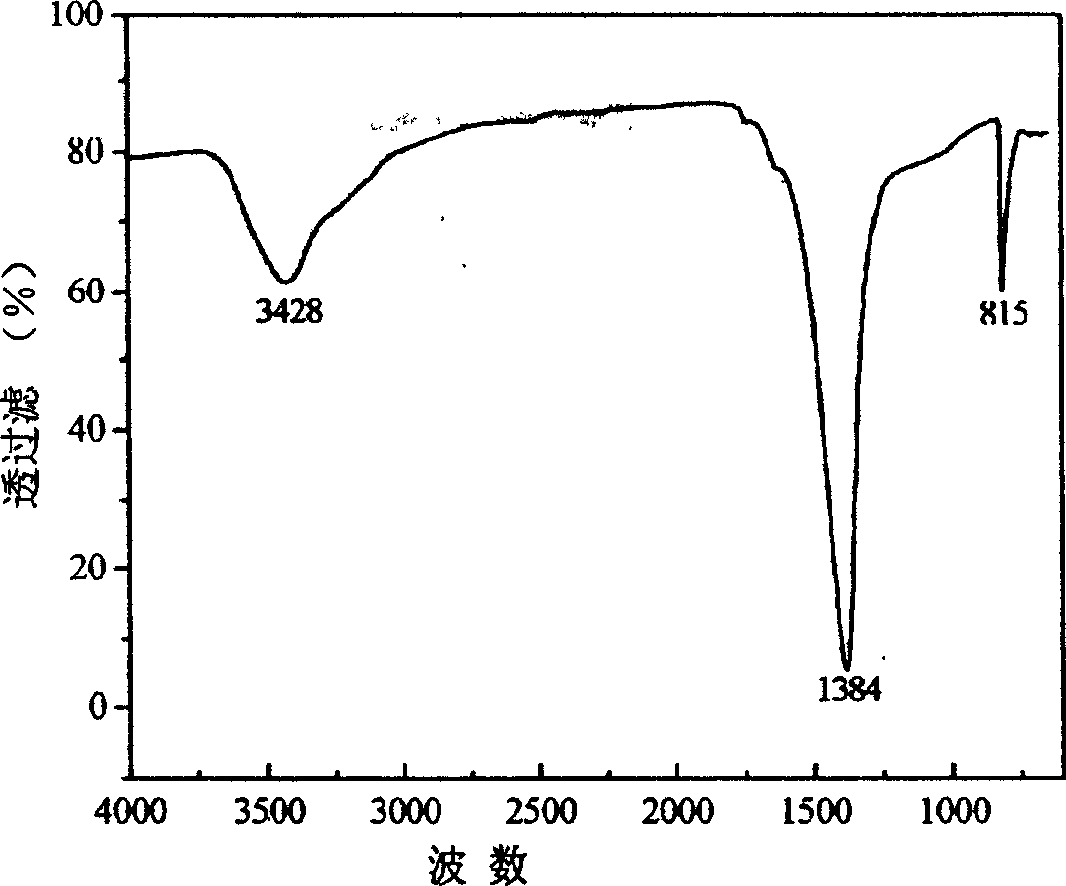

[0025] figure 1 Shown is the X-ray diffraction pattern of the boron nitride nanoring prepared in this example. It can be seen from the figure that the crystallinity and purity of the sample are relatively good, and only hexagonal phase boron nitride is conta...

Embodiment 2

[0026] Embodiment 2: the preparation of boron nitride nanotube

[0027] The raw material for preparing boron nitride nanotubes is H 3 BO 3 , LiN 3 and S.

[0028] First 0.31g H 3 BO 3 , 0.17g Li 3 N and 0.16gS are ground and mixed evenly, pressed into a stainless steel sleeve with a diameter of 6mm at 20MPa, put the sleeve and raw materials into the quartz tube, and then vacuumize the quartz tube, and then fill it with 1 atm Ar gas. After heating the quartz tube to 700°C for 1 hour, and cooling down to room temperature naturally, the product is first treated with carbon disulfide to remove the sulfur contained in the product, then washed with deionized water and suction filtered 3-5 times. The product thus obtained was dried at 80° C. to obtain boron nitride nanotubes.

[0029] Figure 5 It is a scanning photo of boron nitride nanotubes prepared in this embodiment, and the tubular structure of boron nitride can be clearly seen from the figure.

Embodiment 3

[0030] Embodiment 3: the preparation of boron nitride nano ring

[0031] The raw material for preparing boron nitride nanorings is H 3 BO 3 , LiN 3 and NH 4 Cl.

[0032] First 0.31g H 3 BO 3 , 0.17g Li 3 N and 0.27gNH 4 Cl is ground and mixed evenly, pressed into pellets at 20MPa, then put into a quartz tube, vacuumized the quartz tube, and then filled with 1 atm of N 2 . After heating the quartz tube to 600° C. for 1 hour, and cooling down to room temperature naturally, the product is washed with deionized water and suction filtered 3-5 times. The product thus obtained is dried at 80° C. to obtain boron nitride nanorings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com