Method for separating and purifying acetoin in fermentation liquor

A technology of fermented liquid and acetoin, which is applied in the field of bioengineering, can solve the problems of unfavorable rectification and excessive organic acids, and achieve the effects of less water content, less fouling, and lower energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]The impact of different organic solvents of embodiment 1 on the distribution of acetoin

[0034] Add 17.2 g of anhydrous sodium carbonate or 120 g of dipotassium hydrogen phosphate to 100 mL of fermentation clear liquid containing 35 g / L acetoin, stir and dissolve to obtain a salt solution. Take 4 mL each of the salt solution and the organic solvent (shown in Table 1), put them in a graduated 20 mL stoppered test tube, vortex for 1 minute, and then put them in a water bath at 20°C for 8 hours to separate the layers. The upper phase is acetoin-rich The organic phase, the lower phase is a salt-rich aqueous phase. The distribution data of acetoin are shown in Table 1. As can be seen from the data in the table, for structurally similar organic solvents, such as alcohols and acetates, the recovery rate of acetoin decreases as the polarity of the solvent decreases. When organic solvents with high polarity (propanol and butanol) are used, the ratio is relatively large, and th...

Embodiment 2

[0037] The influence of ethanol content on the distribution of acetoin in the solvent of embodiment 2

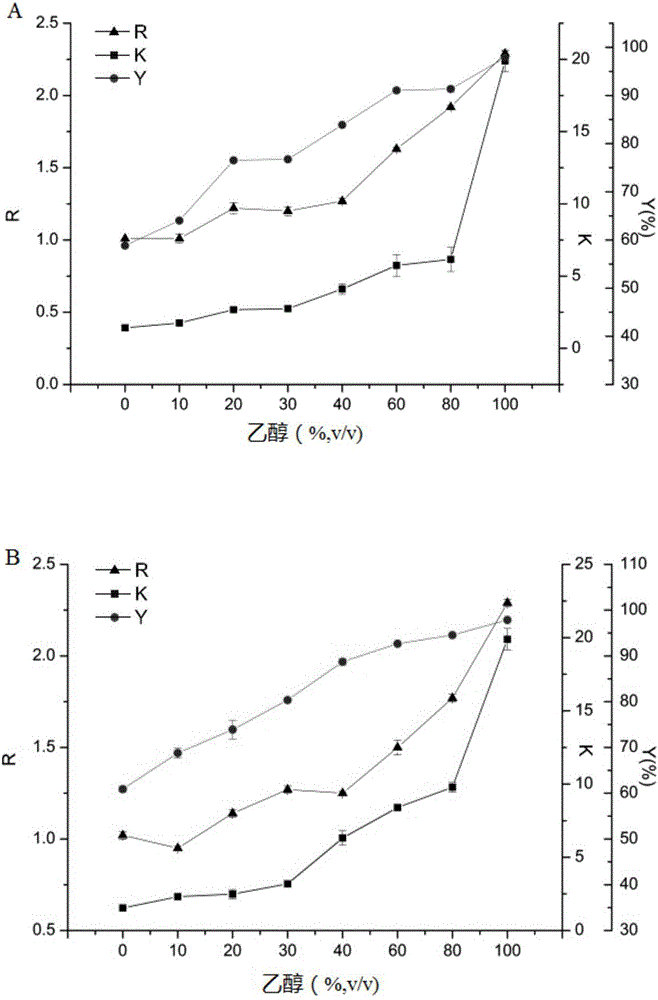

[0038] Put 4mL of fermentation broth containing 60.5g / L acetoin, 2g of inorganic salts and 4mL of solvent into a 20mL stoppered test tube, vortex for 1min, then place it in a water bath at 24°C for 12h, separate layers, and the upper phase is rich in The organic phase of acetoin, the lower phase and the aqueous phase rich in salt, wherein the inorganic salt is dipotassium hydrogen phosphate or potassium pyrophosphate, the solvent is ethyl acetate or methyl tert-butyl ether, and the solvent contains 0~ 100% ethanol, detect the ratio (R) of the upper and lower phases in different extraction systems, the distribution coefficient (K) and the recovery (Y) of acetoin, such as figure 1 shown. figure 1 The salting-out extraction systems of A to D are as follows: A, methyl tert-butyl ether-ethanol / potassium pyrophosphate; B, methyl tert-butyl ether-ethanol / dipotassium hydrogen phosp...

Embodiment 3

[0039] The impact of embodiment 3 salt dosage on the distribution of acetoin

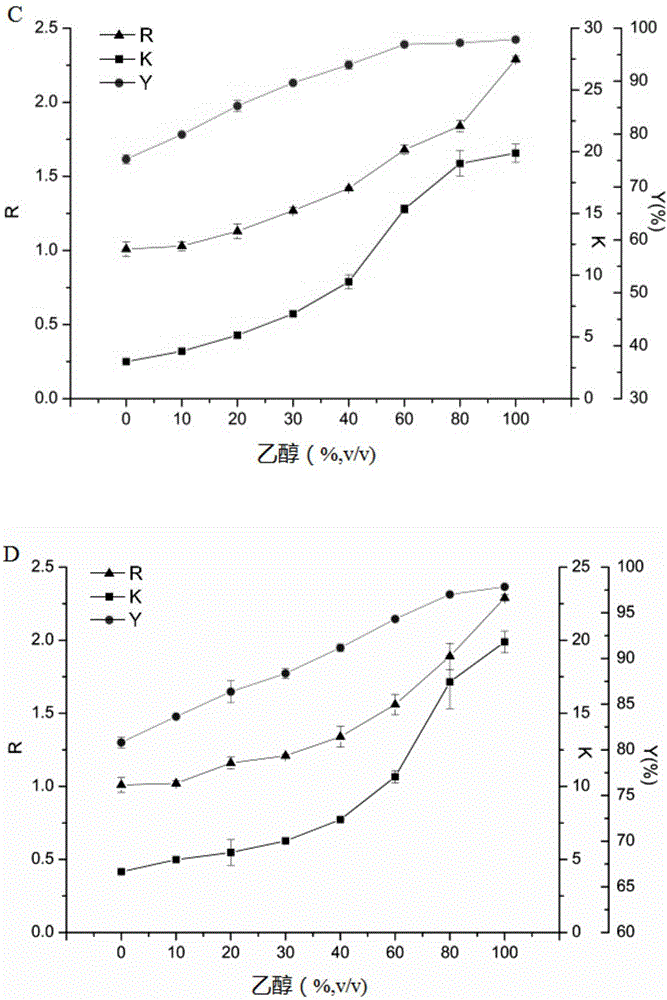

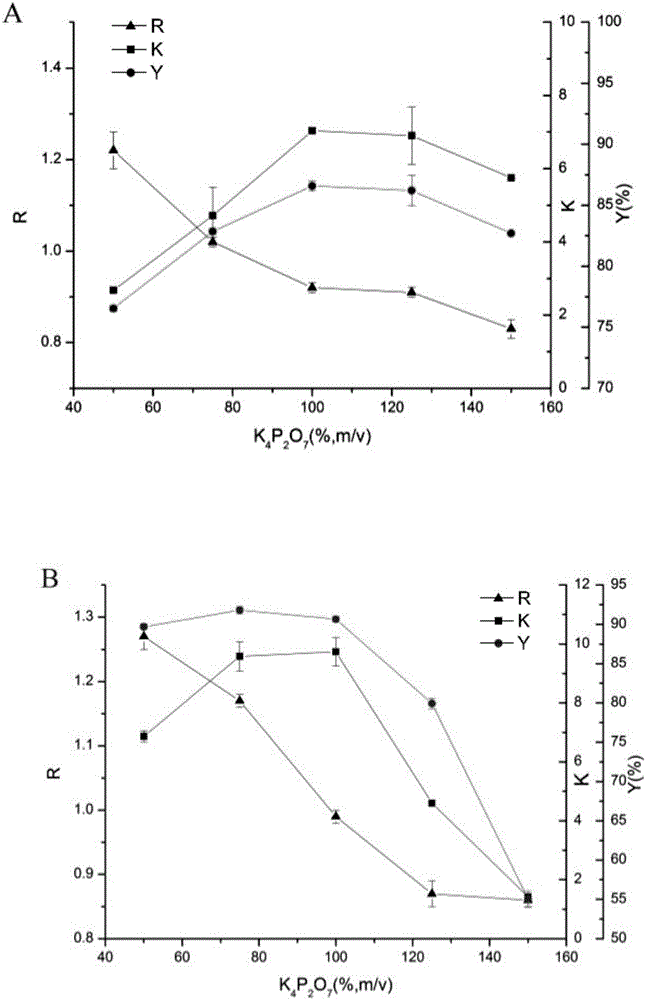

[0040] Place 4 mL of fermentation clear liquid containing 60.5 g / L acetoin, inorganic salts and 4 mL of organic solvent in a 20 mL stoppered test tube, vortex for 1 min, then place in a 24°C water bath for 12 h, and separate layers. The organic phase of dioxin, the lower phase is rich in salt water phase, wherein the inorganic salt is dipotassium hydrogen phosphate or potassium pyrophosphate, and the organic solvent is ethyl acetate or methyl tert-butyl containing 20% or 30% ethanol according to the volume percentage base ether, and detect the ratio (R) of the upper and lower phases, the distribution coefficient (K) and recovery (Y) of acetoin in different salting-out extraction systems, such as figure 2 shown. figure 2 The abscissa in A~D of A~D is the mass volume percentage content of the addition amount of inorganic salt (m, g) to the fermentation broth volume (v, mL), figure 2 The salting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com