Flue gas desulfurizing tower based on Karman vortex street

A desulfurization tower and flue gas technology, applied in the field of desulfurization, can solve the problems of nozzle clogging, difficulty in cleaning, and increased use costs, and achieve the effect of reducing use costs and improving scaling problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

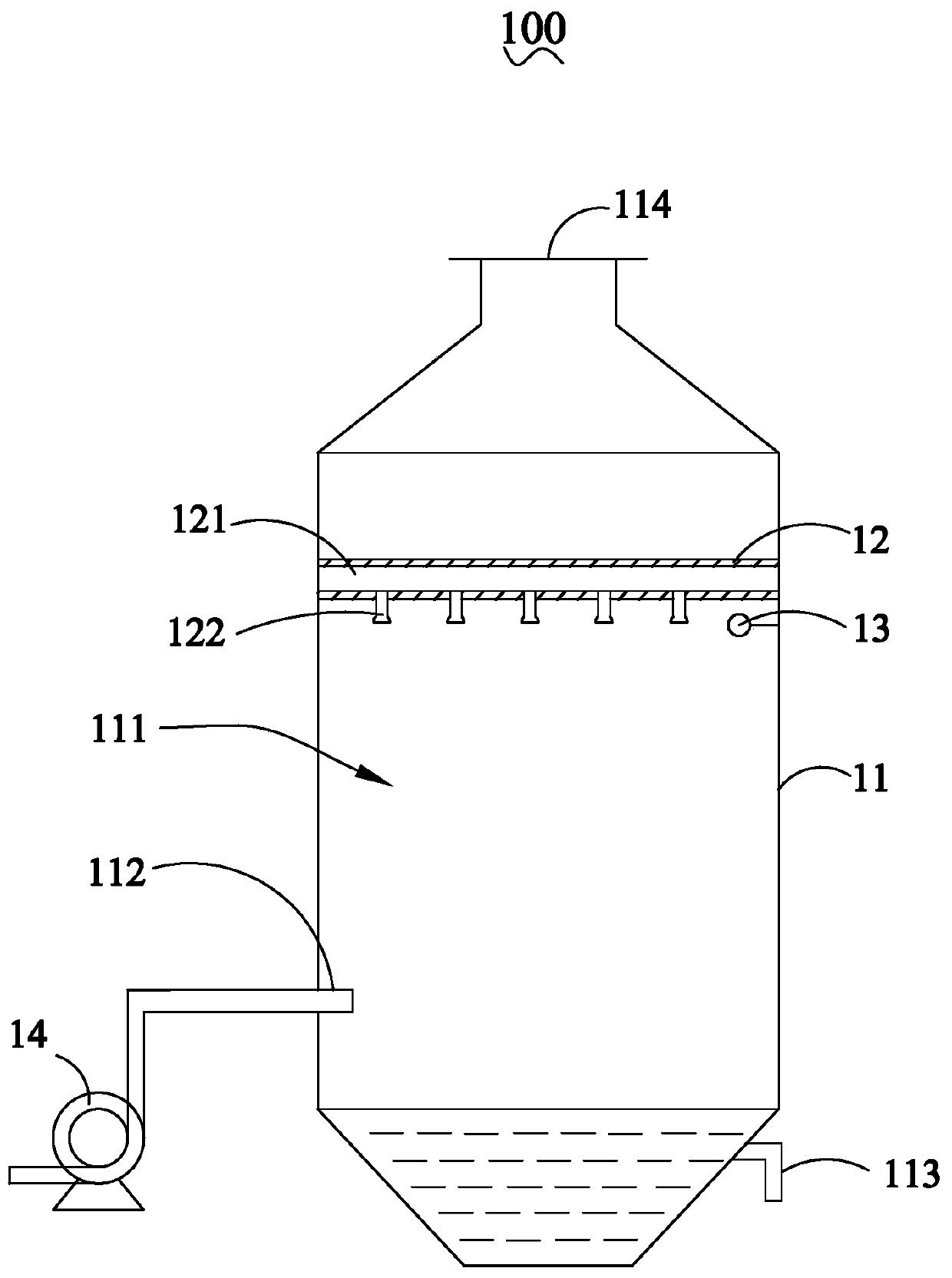

[0029] see figure 1 As shown, the present invention provides a Karman vortex street-based flue gas desulfurization tower 100, including a housing 11 with an internal cavity 111 and a cylindrical Karman vortex street generator 12 disposed in the internal cavity 111, so The bottom of the casing 11 is provided with a flue gas inlet 112 and a water outlet 113, and the top is provided with a gas outlet 114, containing SO 2 The flue gas flows into the housing 11 through the flue gas inlet 112, and the Karman vortex street phenomenon is generated after the flue gas flows through the Karman vortex street generator 12, and the vortex generates on the Karman vortex street generator 12. The periodic alternating lateral force drives the Karman vortex generator 12 to vibrate to achieve the purpose of automatic descaling.

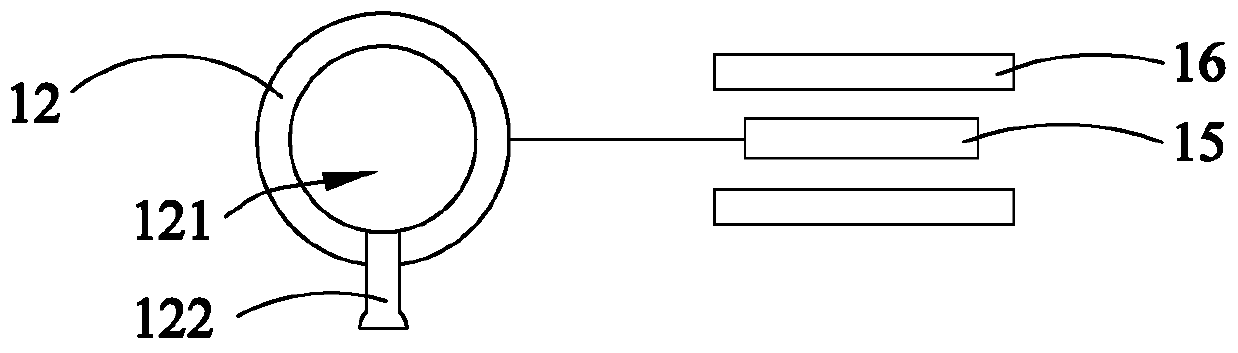

[0030] The Karman vortex generator 12 includes a spray pipe 121 arranged inside it along its length direction and a plurality of nozzles 122 arranged in an array along ...

Embodiment 2

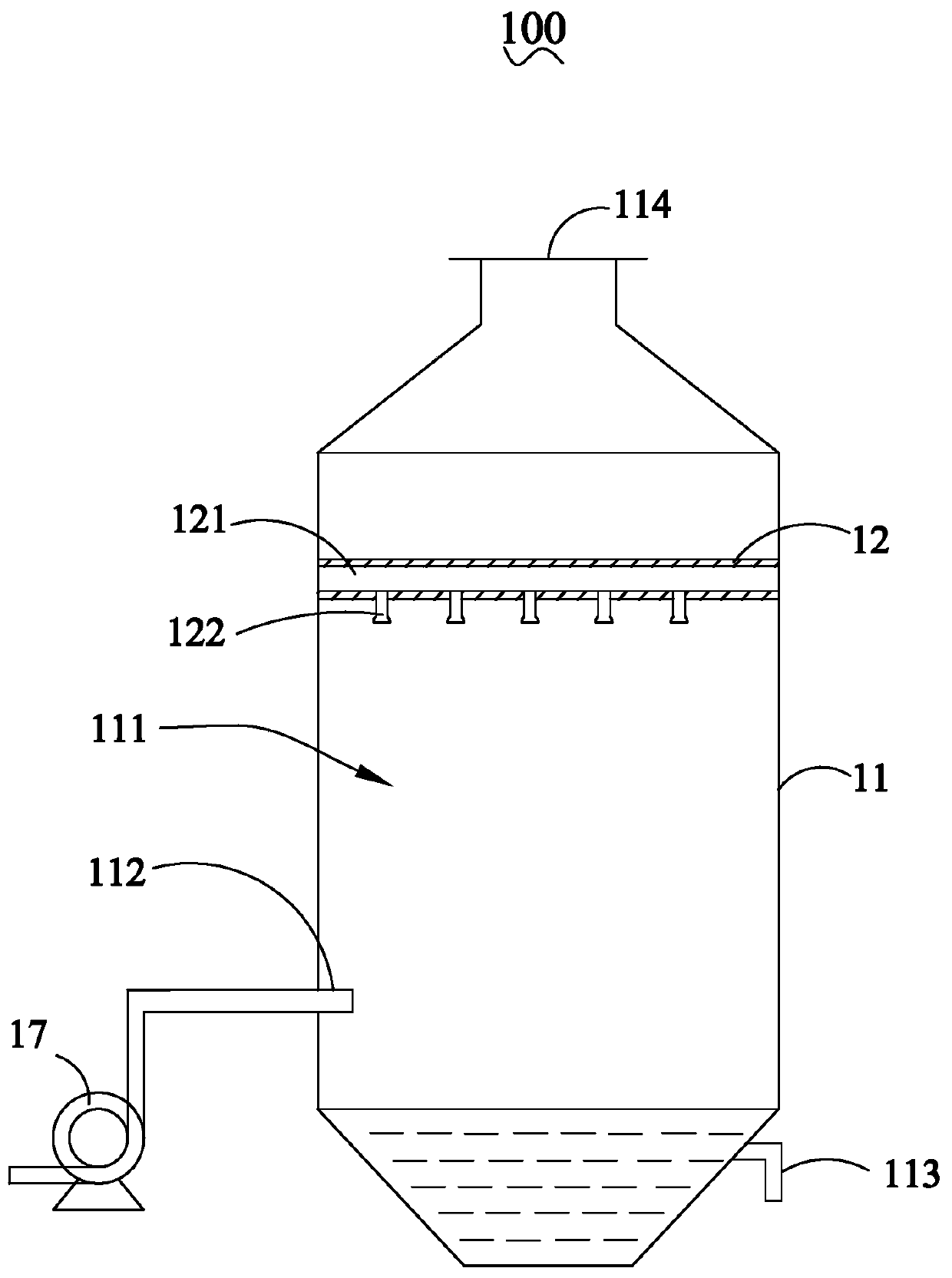

[0034] see figure 2 As shown, the present invention provides a Karman vortex street-based flue gas desulfurization tower 100, including a housing 11 with an internal cavity 111 and a cylindrical Karman vortex street generator 12 disposed in the internal cavity 111, so The bottom of the casing 11 is provided with a flue gas inlet 112 and a water outlet 113, and the top is provided with a gas outlet 114, containing SO 2 The flue gas flows into the housing 11 through the flue gas inlet 112, and the Karman vortex street phenomenon is generated after the flue gas flows through the Karman vortex street generator 12, and the vortex generates on the Karman vortex street generator 12. The periodic alternating lateral force drives the Karman vortex generator 12 to vibrate to achieve the purpose of automatic descaling.

[0035] The Karman vortex generator 12 includes a spray pipe 121 arranged inside it along its length direction and a plurality of nozzles 122 arranged in an array along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com