Evaporative crystallization method for salinity wastewater

A technology for evaporative crystallization, salt-containing wastewater, applied in heating water/sewage treatment and other directions, can solve the problems of poor crystal salt quality, need regular cleaning, insufficient stability, etc., achieve good crystal salt quality, improve scaling problems, Avoid cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

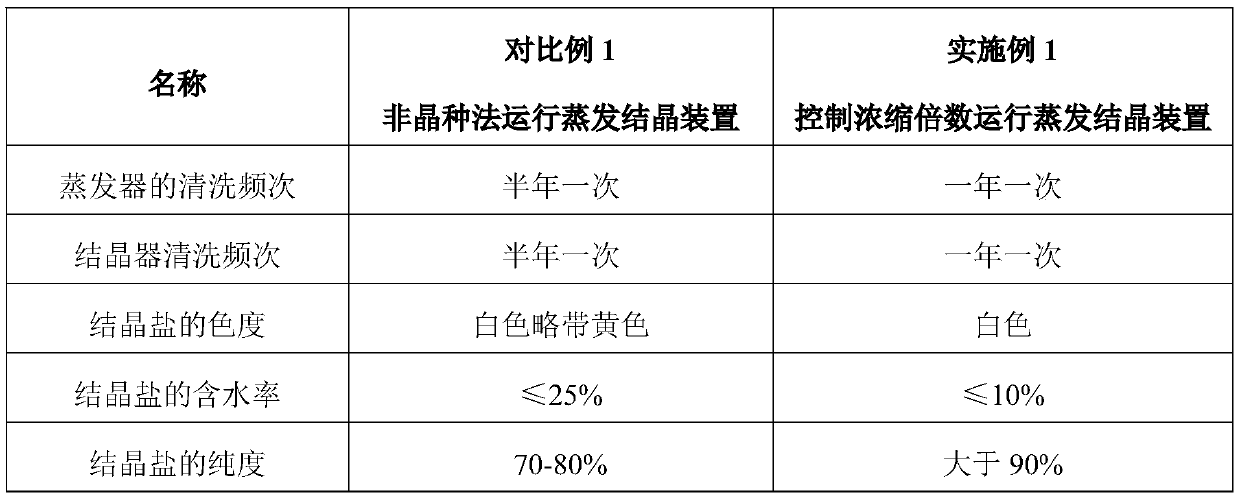

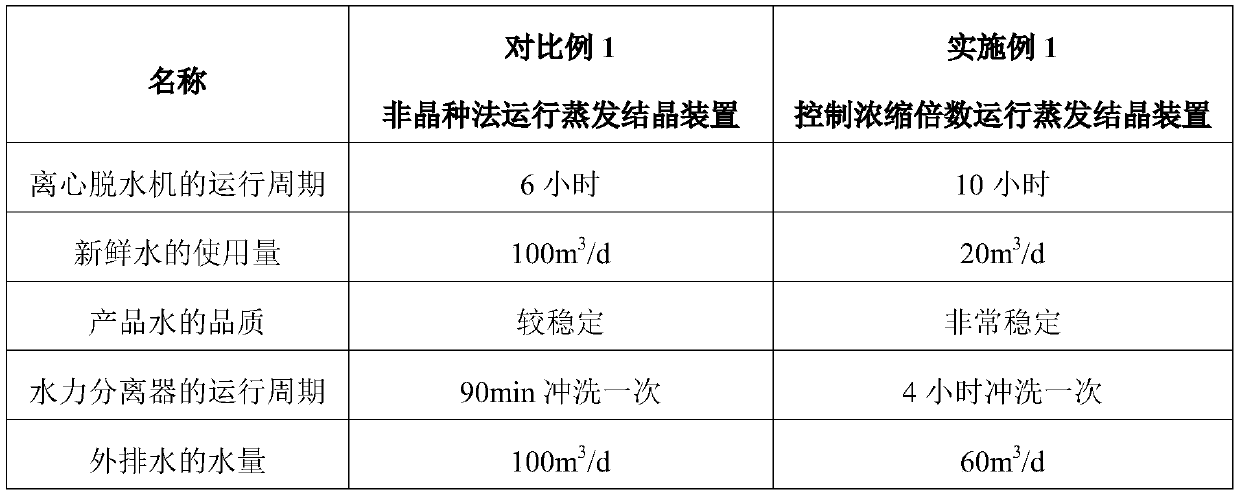

Embodiment 1

[0034] In Example 1, the method provided by the present invention is used to control the concentration ratio of the evaporation system and the crystallization system in real time to treat the embarrassing sewage. details as follows:

[0035] Evaporation process:

[0036] Monitor the pH value, TDS and silica content of the evaporation system every 4 hours. If the values exceed or are not within the control range, the concentration ratio of the evaporation system needs to be adjusted.

[0037] Crystallization process:

[0038] (1) In the initial stage of the operation of the crystallization system, according to the different boiling points of different crystallization salts, the purity and relative content of the crystallization salts are controlled based on this, and the concentration ratio of the crystallization system is controlled based on BPE (boiling point difference); specifically, the front end of the crystallization process generally passes through The concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com