An all-glass tube mvc low-solubility sewage evaporation condensation purification system

An evaporative condensation, low solubility technology, used in water/sewage treatment, water/sewage treatment equipment, heating water/sewage treatment, etc., can solve the problems of high cost, high risk of corrosion and scaling, reduce flow rate and Evaporation resistance, reducing local evaporation and improving the effect of overall heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

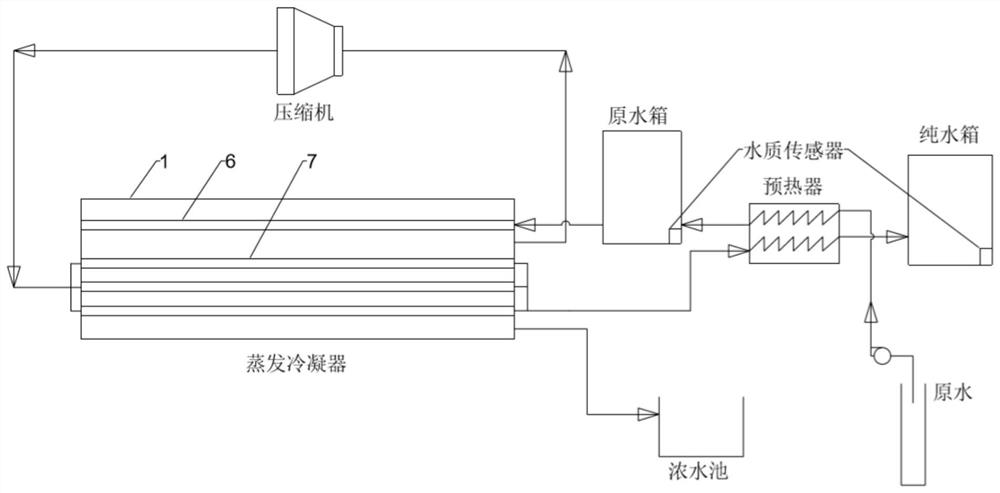

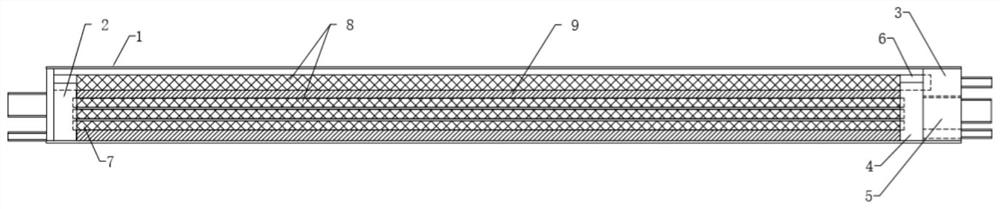

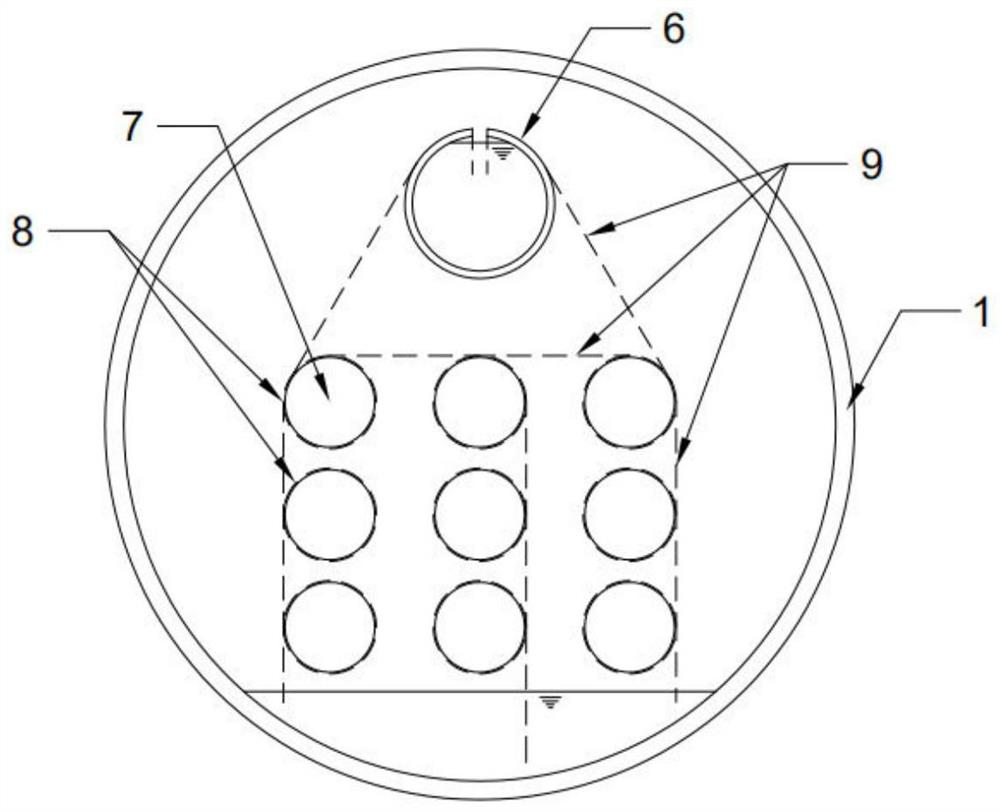

[0024] like figure 1 and Figure 4 As shown, an all-glass tube MVC low-solubility sewage evaporative condensation purification system includes: evaporative condenser, compressor, water pump, glass special-shaped preheater and raw water tank; the raw water enters the raw water tank after passing through the preheater. The preheated raw water from the raw water tank enters the evaporative condenser from the right side, evaporates in the shell tube of the evaporative condenser, and then enters the compressor to obtain high-temperature and high-pressure superheated steam. The superheated steam enters the evaporative condenser on the left side of the evaporative condenser, and The raw water is condensed in the inner tube through heat exchange, and distilled water flows out from the condensation. After the raw water evaporates, the remaining part of the concentrated water flows out from the bottom of the evaporative condenser; the concentrated water finally produced by the system r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com