Method for removing fluorides from coal conversion wastewater

A fluoride and wastewater technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the rare application of fluoride removal, affecting membrane flux and membrane service life, calcium fluoride precipitation It can reduce the problem of small particles and difficult to separate, so as to prolong the cleaning cycle and service life, improve the scaling problem on the membrane surface, and reduce the concentration of fluoride ions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

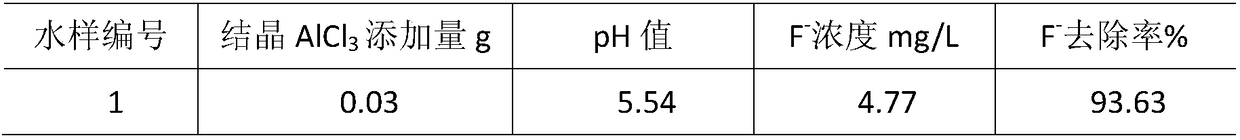

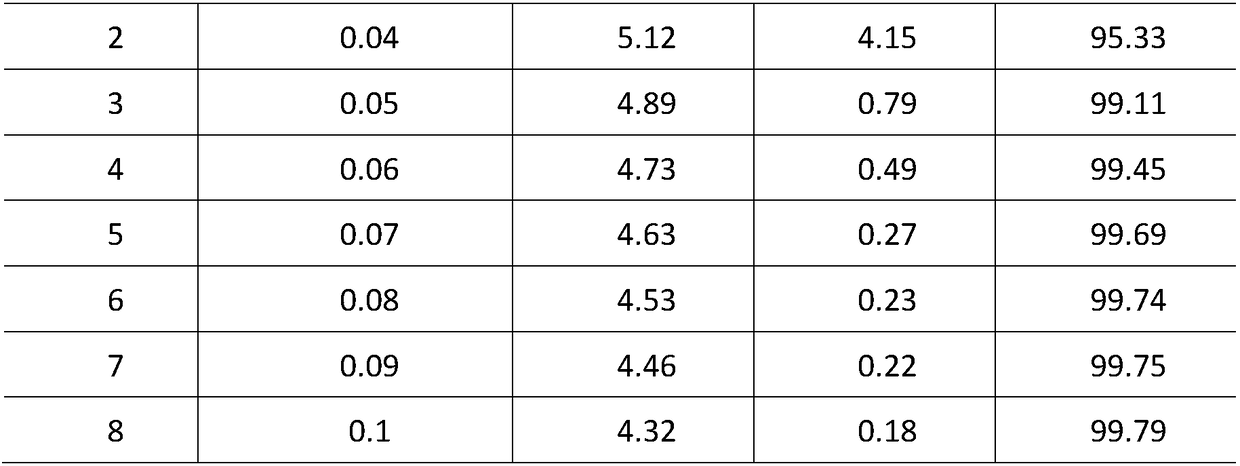

[0021] Prepare a water sample containing 55mg / L fluorine, and the pH value of the water sample is measured by the Shanghai Lei Magnetic pH meter. 0.08g, 0.09g, 0.1g crystalline aluminum chloride AlCl 3 , the water sample is less and the water quality is simple, just simply stir until the crystalline aluminum chloride is completely dissolved in the water, let it stand for 5 minutes, and the flocculation and precipitation can completely settle. The experimental data show that with the increasing amount of crystalline aluminum chloride, the removal rate of fluoride ions increases, as shown in Table 1. Fluoride ion meter selective electrode method to test the concentration of fluoride ion.

[0022] Table 1

[0023]

[0024]

Embodiment 2

[0026] Water samples containing 100mg / L, 200mg / L, 300mg / L, and 400mg / L of fluorine were respectively configured in the laboratory, and with the experimental method of the above-mentioned embodiment 1, different amounts of crystalline aluminum chloride were added, and the selective electrode of the fluoride ion meter method to measure the fluoride ion concentration, the experiment found that:

[0027]For water samples containing 100mg / L fluorine, when the amount of crystalline aluminum chloride added is 0.5g / L, the fluoride ion removal rate reaches the best of 99.33%, and the fluoride ion concentration is 0.37mg / L;

[0028] For water samples containing 200mg / L fluorine, when the amount of crystalline aluminum chloride added is 1.0g / L, the removal rate of fluoride ion reaches the best of 99.28%, and the concentration of fluoride ion is 1.44mg / L;

[0029] For water samples containing 300mg / L fluorine, when the amount of crystalline aluminum chloride added is 1.5g / L, the removal r...

Embodiment 3

[0033] Water samples from biochemical treatment wastewater from coal gasification plant, the main water quality indicators are: fluoride ion concentration is 55.0mg / L, calcium ion concentration is 10.57mg / L, ammonia nitrogen concentration is 13.2mg / L, sulfate ion concentration is 475.5mg / L L, the chloride ion concentration is 50.8mg / L, the COD is 342mg / L, and the pH value is 7.4.

[0034] Take 300mL of this water sample and divide it into 3 parts of 100mL each, add 0.5g / L crystalline AlCl 3 , polyaluminum chloride, anhydrous calcium chloride, the fluoride ion concentrations measured by the selective electrode method of fluoride ion meter are 4.95mg / L, 7.15mg / L, 19.25mg / L respectively, and the removal rates are 91% and 87% respectively , 65%, it can be seen from the experimental data that under the same addition amount, the use of crystalline AlCl 3 The defluoridation effect of the coagulant is the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com