Vacuum low-temperature evaporation concentration treatment method of landfill leachate

A technology of landfill leachate and vacuum evaporation, which is applied in chemical instruments and methods, heating water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as high operating costs, high cleaning frequency, and easy corrosion and scaling. Achieve the effect of reduced process energy consumption, increased evaporation rate, and improved scaling and corrosion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

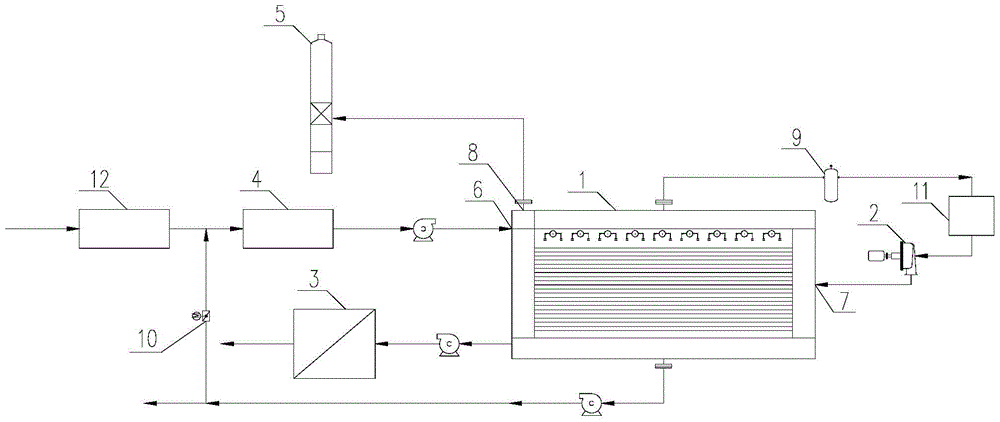

[0028] The device of this embodiment is as figure 1 As shown, the implementation steps are as follows:

[0029] (1) Garbage leachate selectively enters the pretreatment mechanism 12 according to the water quality of the influent, such as including primary sedimentation tank (for sedimentation), adjustment tank (for homogenization (stirring evenly) and equalization (controlling water output), filter ( Filtration), pH adjustment, etc., the pH adjustment is to add nitric acid to a pH of about 5. Then the pretreated raw water is heated by the first heater 4 .

[0030] (2) Operate the vacuum compressor 2 to pump the evaporator 1 to a vacuum state, control the operating pressure of the evaporator 1 at 4.5-7.5kPa, and control the evaporation temperature at 35±5°C. The pretreated leachate is sent to the feed port 6 of the evaporator 1 under pressure, and is treated and separated into steam and concentrated liquid by the evaporator 1 .

[0031] (3) After being separated by steam-wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com