Baffled Fenton oxidation reactor and organic wastewater treatment method

A Fenton oxidation and organic wastewater technology, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of difficult removal of solids, unfavorable rapid response, etc., and improve the efficiency of Fenton treatment , shorten the residence time, reduce the effect of back mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

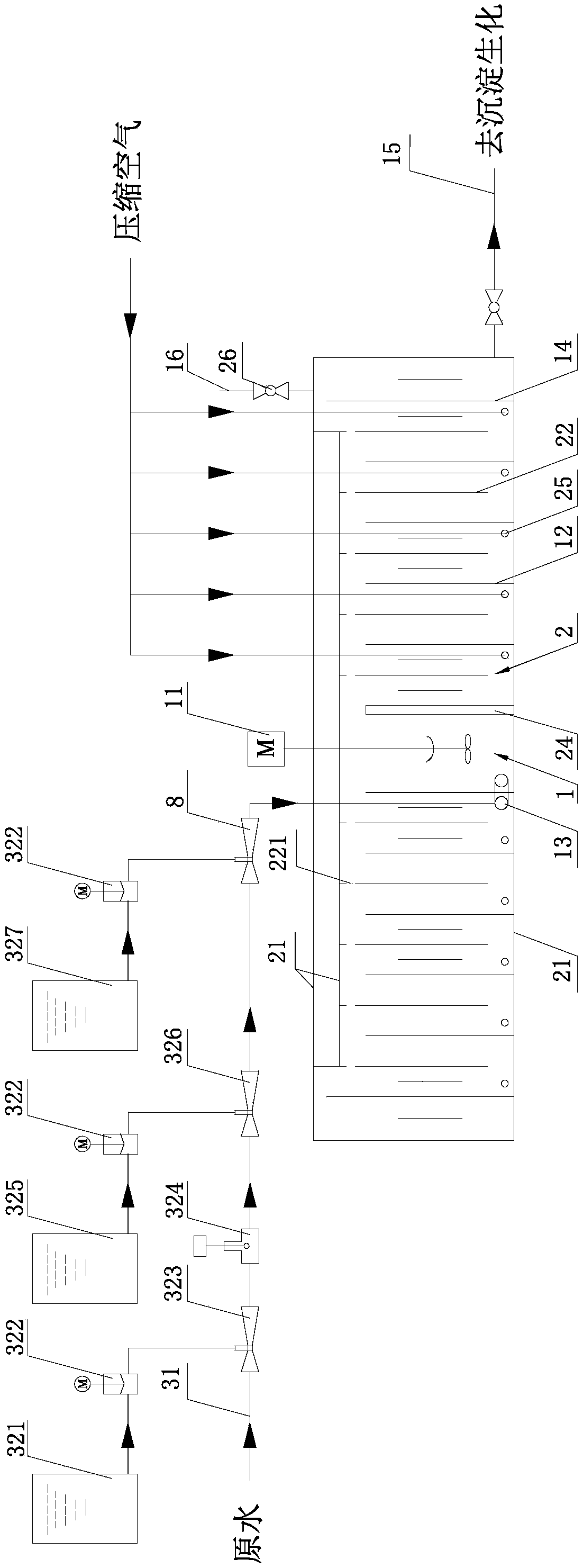

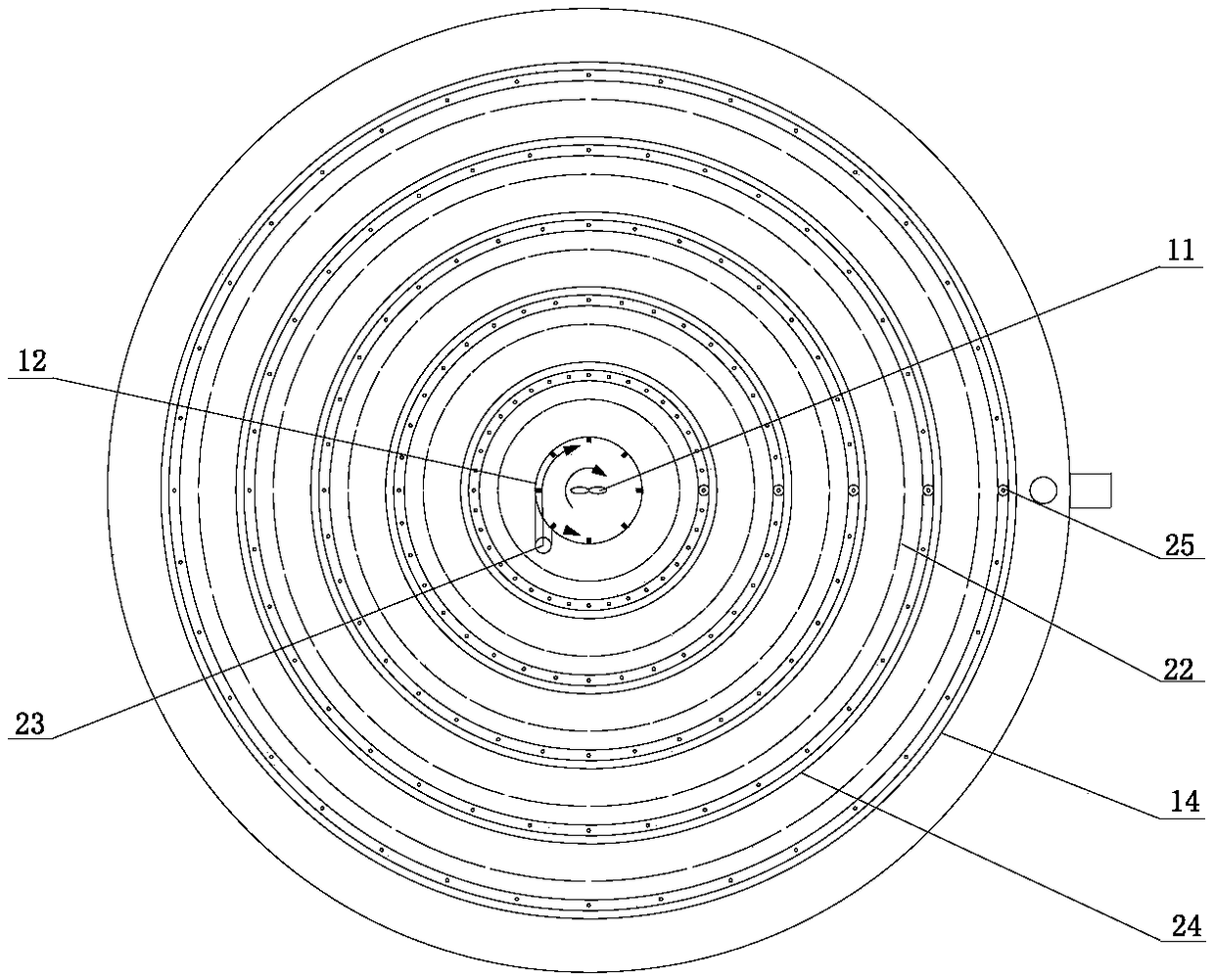

[0045] The flow rate of organic wastewater is 0.2m3 / h, the CODCr is 3620mg / L, the size of the designed baffle reactor is Φ500×120mm, there are 8 sets of upper and lower baffle tubes inside, the air-water ratio is 3:1, and the motor is stirred Speed at 50RPM, FeSO 4 Solution (Fe2+ molar concentration is 1.42mol / L) dosage is 13.6L / h, H 2 o 2 The dosage of solution (27.5%, w / w) was 4L / h, and CODCr decreased from 3620mg / L to 500mg / L after treatment.

Embodiment 2

[0047] The flow rate of organic wastewater is 1m3 / h, the CODCr is 8050mg / L, and the designed baffled reactor has a size of Φ900×200mm. There are five sets of upper and lower baffled tubes 22 and 24 inside, and the air-water volume ratio is 10:1. , motor stirring speed is 100RPM, FeSO 4 The dosage of the solution (Fe2+ molar concentration is 1.42mol / L) is 44.4L / h, the dosage of H2O2 solution (27.5%, w / w) is 20L / h, and the CODCr drops from 8050mg / L to 2100mg / L after treatment .

Embodiment 3

[0049] The flow rate of organic wastewater is 4.2m3 / h, CODCr is 12000mg / L, the designed baffled reactor has a size of Φ1200×900mm, and there are 10 sets of upper and lower baffled tubes inside, the gas-water volume ratio is 8:1, and the stirring speed of the motor is 250RPM, FeSO 4 Solution (Fe 2 + molar concentration is 1.42mol / L) dosage is 185L / h, H2O2 solution (27.5%, w / w) dosage is 105L / h, after treatment CODCr drops from 12000mg / L to 4800mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com