Premixing device capable of mixing natural gas drag reducers step by step

A technology of drag reducing agent and natural gas, applied in mixer, transportation and packaging, dissolving and other directions, can solve the problems of inability to implement construction cost, lower inner coating and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

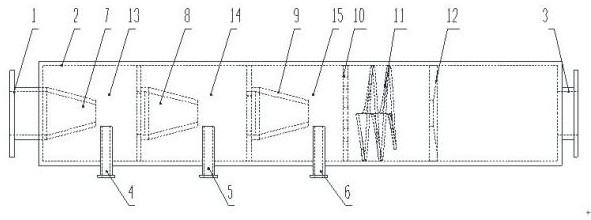

[0024] The structural layout, operation process and innovations of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

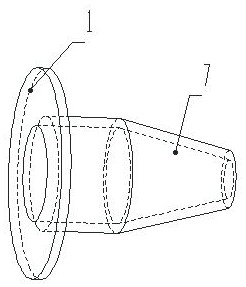

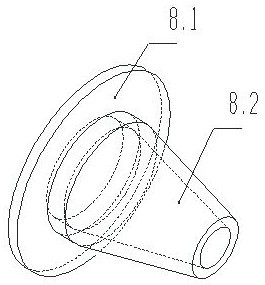

[0025] See attached Figure 1~6 , a kind of step-by-step blending natural gas drag reducer premixing device of the present invention, comprising a shell 2, the shell 2 is a long cylindrical structure, the natural gas inlet 1 is located at the center of one end of the shell 2, and the atomized drag reducer outlet 3 is located at The center of the other end of the housing 2; inside the housing 2, the first jet nozzle 7, the second jet nozzle 8, and the third jet nozzle are sequentially arranged along the axis of the housing from one end of the natural gas inlet 1 to the atomized drag reducer outlet 3. The nozzle 9 and the spiral blade 11, the natural gas inlet 1 is connected to the first jet nozzle 7, the first jet nozzle 7 extends into the space as the first mixing chamber 13, the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com