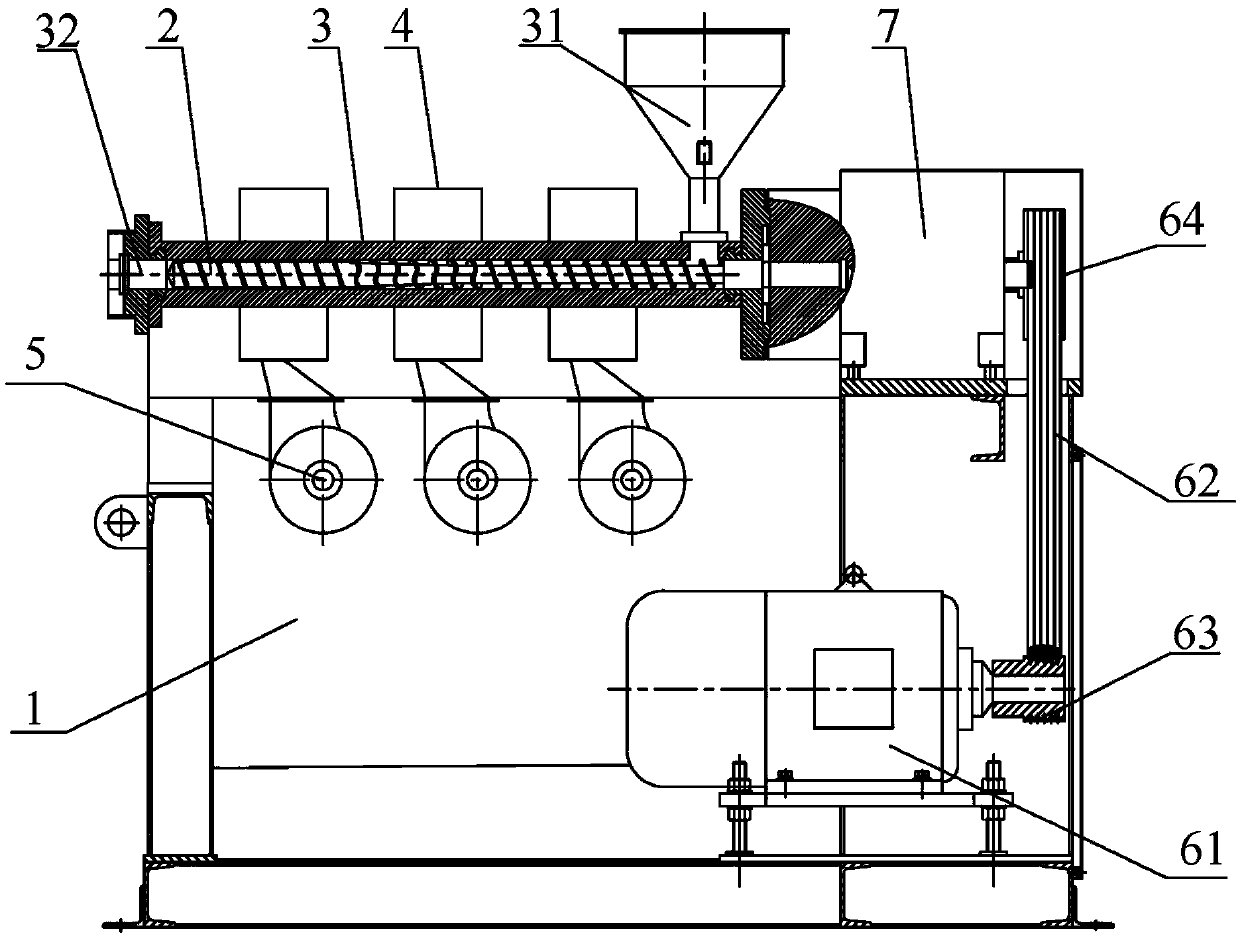

A single-screw plasticizing extruder

An extruder and single-screw technology, applied in the field of polymer material processing and molding equipment, can solve the problems of inability to match the solid conveying efficiency with the melt conveying efficiency, restricting the application range of the single-screw extruder, and low melting and plasticizing efficiency. , to achieve the effect of increasing the maximum shear rate, simple structure and improving plasticizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

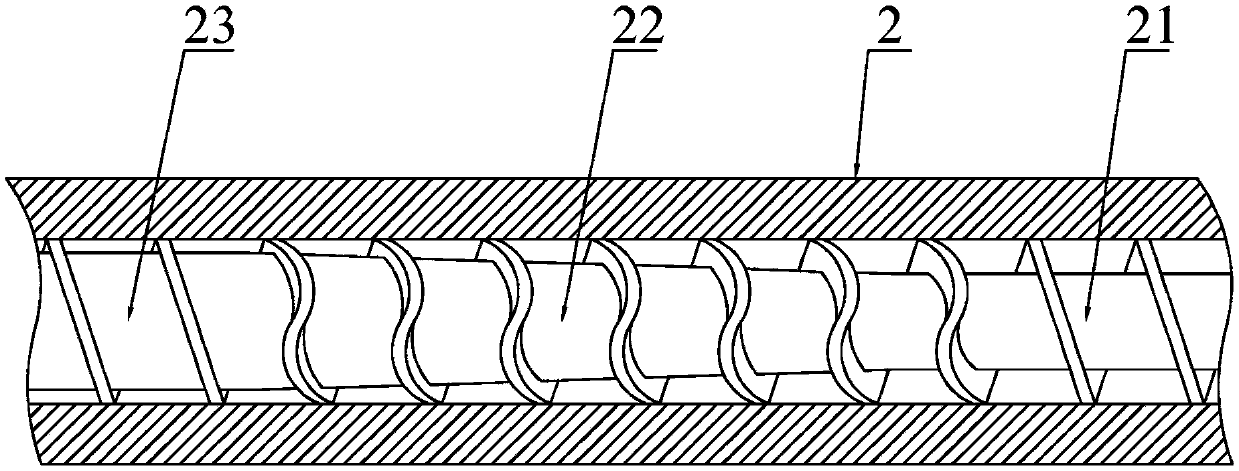

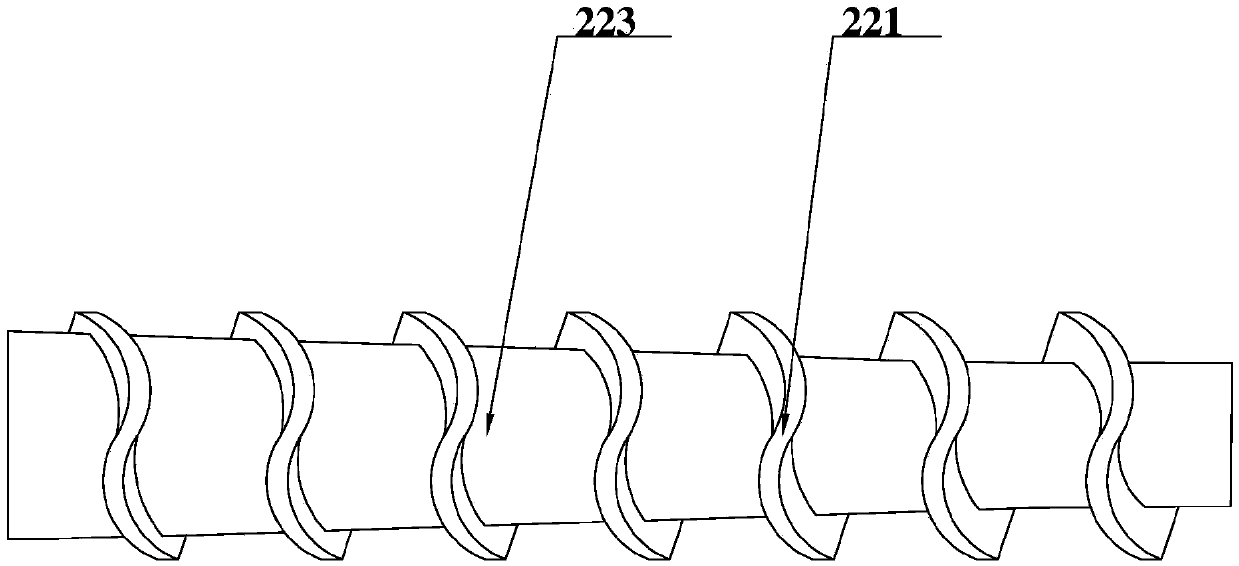

[0044] The single-screw plasticizing extruder provided in this embodiment, Shape helicoid 221 expands along its helical direction and the trajectory on the same plane satisfies the following function:

[0045] y=a sin(πb x)

[0046] Wherein, the direction of the helical expansion line 222 is the direction of the x-axis, the direction perpendicular to the helical expansion line 222 is the direction of the y-axis, a is 0.1D, b is 5 / D, and D is the nominal diameter of the screw 2. The screw of this embodiment The nominal diameter D is 65mm.

[0047] The screw groove depth of the solid conveying section 21 is 6.5mm, the screw groove depth of the melt conveying section 23 is 3mm, and the thread lead angles of the solid conveying section 21 and the melt conveying section 23 are both 17°42'; the screw groove of the melting section 22 The groove depth gradually decreases from 6.5mm at the front end to 3mm at the rear end along the axis of the screw 2, and the melting section The ...

Embodiment 2

[0051] The difference between the single-screw plasticizing extruder in this embodiment and the single-screw plasticizing extruder in Embodiment 1 is that Shape helicoid 221 expands along its helical direction and the trajectory on the same plane satisfies the following function:

[0052] y=a sin(πb x)

[0053] Wherein, the direction of the helical expansion line 222 is the direction of the x-axis, the direction perpendicular to the helical expansion line 222 is the direction of the y-axis, a is 0.15D, b is 3 / D, and D is the nominal diameter of the screw 2. The screw of this embodiment The nominal diameter D is 90mm.

[0054] The screw groove depth of the solid delivery section 21 is 9mm, the screw groove depth of the melt delivery section 23 is 4mm, and the screw lead angles of the solid delivery section 21 and the melt delivery section 23 are both 17°42'; the depth of the screw groove of the melting section 22 is determined by The 9mm of its front end gradually decreases ...

Embodiment 3

[0058] Compared with the single-screw plasticizing extruder in Embodiment 1, the single-screw plasticizing extruder in this embodiment is different in that, Shape helicoid 221 expands along its helical direction and the trajectory on the same plane satisfies the following function:

[0059] y=a sin(πb x)

[0060] Wherein, the direction of the helical expansion line 222 is the direction of the x-axis, the direction perpendicular to the helical expansion line 222 is the direction of the y-axis, a is 0.25D, b is 2 / D, and D is the nominal diameter of the screw 2. The screw of this embodiment The nominal diameter D is 70mm.

[0061] The screw groove depth of the solid delivery section 21 is 7mm, the screw groove depth of the melt delivery section 23 is 3.5mm, and the thread angles of the solid delivery section 21 and the melt delivery section 23 are both 17°42'; the melting section 22 screw groove depth From the 7mm of its front end to the 3.5mm of its rear end along the axial d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com