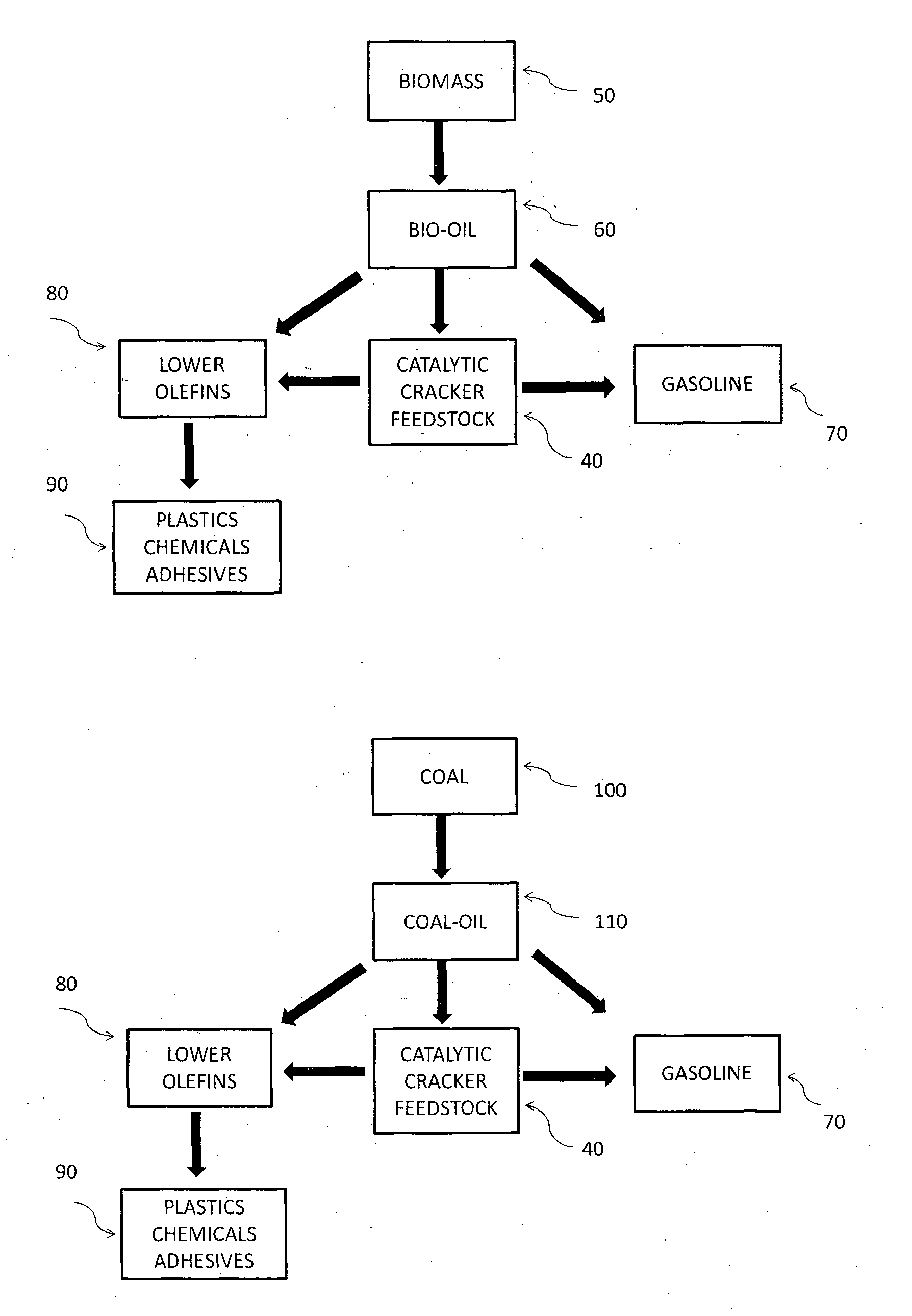

Methods for Producing Hydrocarbon Products from Bio-Oils and/or Coal-Oils

a bio-oil and hydrocarbon product technology, applied in the direction of hydrocarbon oil treatment products, fuels, thermal non-catalytic cracking, etc., can solve the problems of further increases in the price of gasoline, adverse environmental effects of sulfur and nitrogen-containing compounds in crude oil, and potential global shortages of gasoline in the future, so as to reduce adverse environmental effects and/or economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Cracking of Lignite and Bio-Oil Syncrudes

[0172]FIG. 9 shows a schematic of a Micro Activity Test (MAT) unit comprising a fixed bed of catalyst contained in a Pyrex glass reactor supported in a temperature controlled furnace. The lignite and bio-oil syncrudes were Used as feeds to the MAT unit as follows:

Condensate (lignite oil)Syncrude (Bio-oil)100090107030

[0173]The MAT unit that was operated at the conditions shown below:[0174]Contact Time (TOS): 30 seconds[0175]Catalyst to Oil Ratio (CTO): 2-6 (WHSV=20-60 h−1)[0176]Temperature=500° C.[0177]Catalytic Cracking Equilibrium Catalyst:[0178]surface area 290 m2 / g; ˜30% zeolite Y with a unit cell dimension (UCS) of 24.28 Å

[0179]The catalyst was charged to the reactor and preheated under nitrogen flow. The catalyst was an equilibrium sample with the properties given above.

[0180]The syncrude feeds were injected at a controlled rate using a syringe pump. Following the feed injection cycle, remaining hydrocarbons are stripped from the catalys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com