Production of large-specific-weight aircraft liquid petroleum oil at maximum from coal liquefied oil

A technology for coal liquefied oil and aviation kerosene, which is used in the preparation of liquid hydrocarbon mixtures, petroleum industry, and refining to remove heteroatoms, etc., can solve the problems of low specific gravity of aviation kerosene production and low yield of aviation kerosene production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

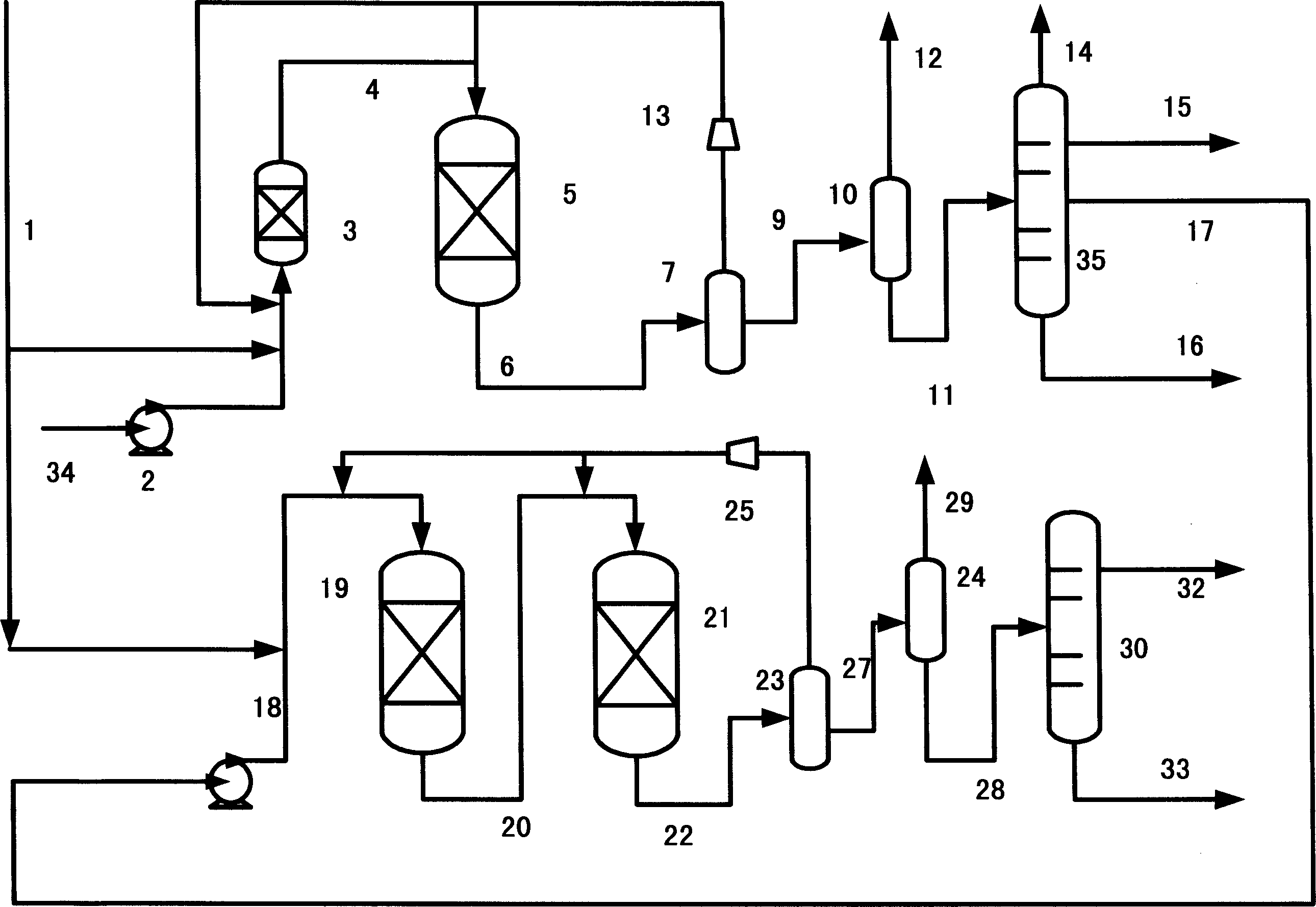

Image

Examples

Embodiment

[0044] The reaction conditions and properties of the reaction products in the stable hydrogenation step are listed in Tables 2-3 respectively. Tables 4 to 5 are lists of properties of feedstock oil, reaction conditions, and properties of reaction products in the hydrogenation upgrading step. It can be seen from Table 1 that the nitrogen and oxygen content of coal liquefied oil before stable hydrogenation are high, and the bromine value is high. The data in Table 3 shows that after the stable hydrogenation, the nitrogen content dropped significantly, and the bromine value also dropped to a very low level, achieving the purpose of stable hydrogenation. The data in Tables 4 to 6 show that the smoke point of the hydrogenation upgrading feedstock is very low, only 11mm, and it reaches 23mm after hydrogenation upgrading, and the density is greater than 0.84g / cm 3 , The properties such as flash point and freezing point also meet the index requirements of aviation kerosene with large...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com