Method for recycling gold in cyanided tailings in ramified and series flotation mode

A branched flow, cyanidation tailings technology, applied in flotation, solid separation and other directions, can solve the problems of difficulty in gold extraction by flotation of fine-grained cyanide slag, decrease in flotability, and environmental pollution, and achieve significant technical and The effect of economic benefits, improved floatability, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

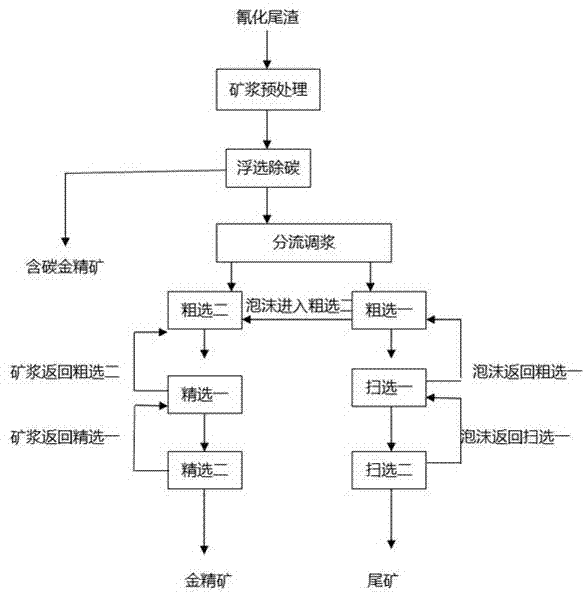

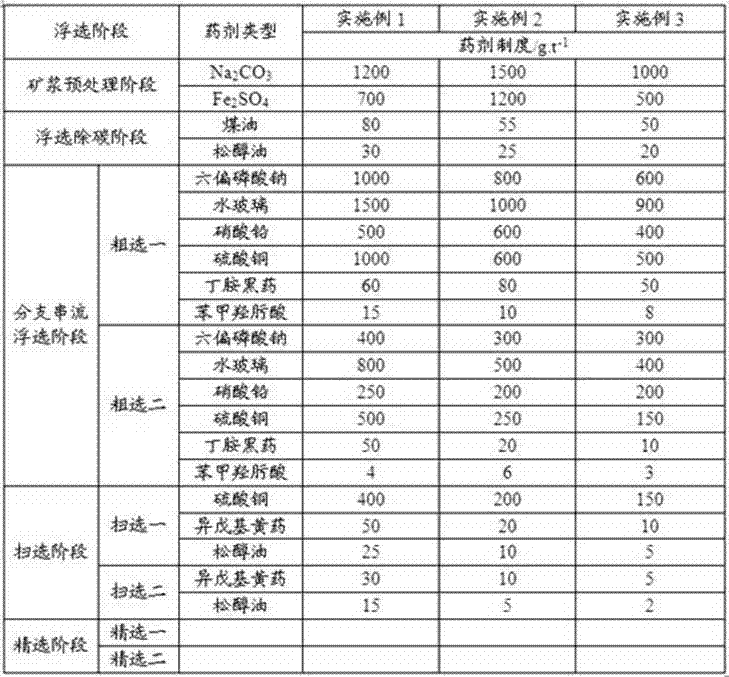

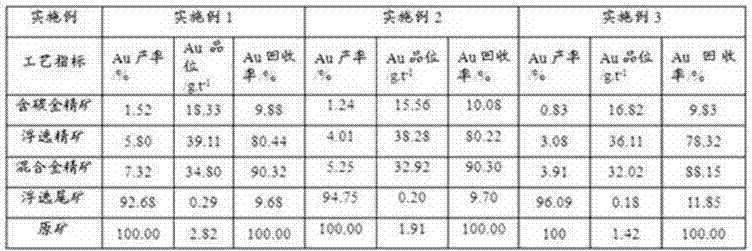

[0017] A method for recovering gold in cyanidation tailings by branch series flotation, comprising the following steps:

[0018] The whole mud cyanidation tailings contain Au2.82g / t, carbon content 1.32%, sulfur content 0.92%, add water to adjust the slurry concentration to 20-40%, and stir continuously at normal temperature and pressure for 5-7 minutes, according to the chemical formula listed in Table 1, After stirring well, add Na 2 CO 3 , Fe 2 SO 4 Slurry pH = 7 ~ 8, pump the pretreated pulp into the stirring buffer tank, continue to stir for 15 to 20 minutes, flow into the slurry tank, add kerosene and terpineol oil, fully stir for 3 minutes, and the pulp enters the flotation machine Flotation decarbonization is carried out, and the foam product is filtered to obtain carbon-containing gold concentrate; the decarbonized pulp flows to the stirring distribution tank by itself, and the stirring distribution tank distributes the pulp evenly to the two mixing tanks. Add min...

Embodiment 2

[0021] A method for recovering gold in cyanidation tailings by branch series flotation, comprising the following steps:

[0022] A certain all-slimed cyanide tailings contains Au1.91g / t, carbon 1.15%, sulfur 0.52%, add water to adjust the slurry concentration to 20-40%, stir continuously at normal temperature and pressure for 5-7 minutes, according to the chemical formula listed in Table 1 , formula, after stirring evenly, add Na 2 CO 3 , Fe 2 SO 4 Slurry pH = 7 ~ 8, pump the pretreated pulp into the stirring buffer tank, continue to stir for 15 to 20 minutes, flow into the slurry tank, add kerosene and terpineol oil, fully stir for 4 minutes, and the pulp enters the flotation machine Flotation decarbonization is carried out, and the foam product is filtered to obtain carbon-containing gold concentrate; the decarbonized pulp flows to the stirring distribution tank by itself, and the stirring distribution tank distributes the pulp evenly to the two mixing tanks. Add mineral...

Embodiment 3

[0025] A method for recovering gold in cyanidation tailings by branch series flotation, comprising the following steps:

[0026] A certain all-slimed cyanide tailings contains Au1.42g / t, carbon 0.92%, sulfur 0.22%, add water to adjust the slurry concentration to 20-40%, stir continuously at normal temperature and pressure for 5-7 minutes, according to the chemical formula listed in Table 1 , formula, after stirring evenly, add Na 2 CO 3 , Fe 2 SO 4 Slurry pH = 7 ~ 8, pump the pretreated pulp into the stirring buffer tank, continue to stir for 15 to 20 minutes, flow into the slurry tank, add kerosene and terpineol oil, fully stir for 5 minutes, and the pulp enters the flotation machine Flotation decarbonization is carried out, and the foam product is filtered to obtain carbon-containing gold concentrate; the decarbonized pulp flows to the stirring distribution tank by itself, and the stirring distribution tank distributes the pulp evenly to the two mixing tanks. Add mineral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com