Delay coking hydrogenation combined process for coal oil

A delayed coking and combined process technology, applied in the field of coal chemical industry, can solve problems such as air pollution and dust pollution, and achieve the effect of reducing environmental pollution and increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples illustrate the present invention further:

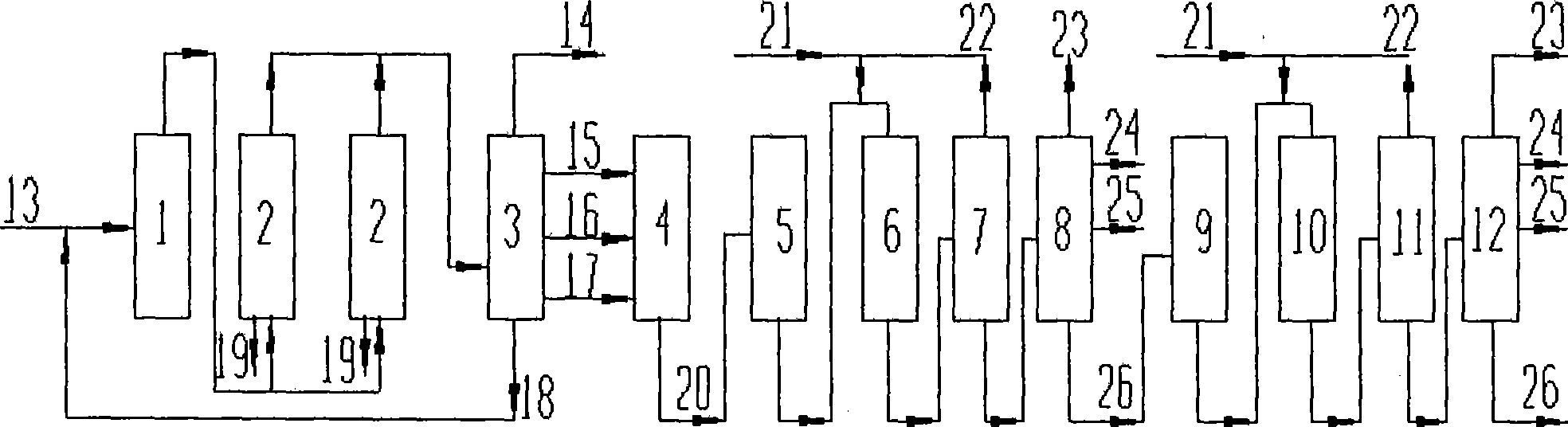

[0022] combine figure 1 In this embodiment, the coal tar 13 preheated to 300-400°C is heated to 450-550°C in the delayed coking heating furnace 1 and then enters the coke tower 2, and the oil produced after the coking reaction enters the delayed coking fractionation tower 3 for fractional distillation. Coked gasoline 15, coked diesel oil 16, and coked wax oil 17 enter the intermediate mixing tank 4. During the operation, the pressure of the coke tower is controlled at 0.28Mpa, and the temperature is controlled between 450-550°C. The two coke towers are operated in a period of 18 hours or 24 hours. 19. At the same time, the fuel gas 14 is separated from the upper part of the coking fractionation tower 3 and enters the fuel gas pipeline network after being desulfurized. The circulating oil 18 is separated at the bottom of the coking fractionation tower 3 and returned to the entrance of the delayed coking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com