Preparation method of mesocarbon microbead

A technology of mesophase carbon microspheres and mesophase, which is applied in the field of preparation of mesophase carbon microspheres, can solve the problems of low separation efficiency of mesophase carbon microspheres, large solvent consumption, and low product yield, and achieve low cost , Narrow particle size distribution and excellent dispersion

Inactive Publication Date: 2010-08-25

SHANGHAI INST OF TECH

View PDF5 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

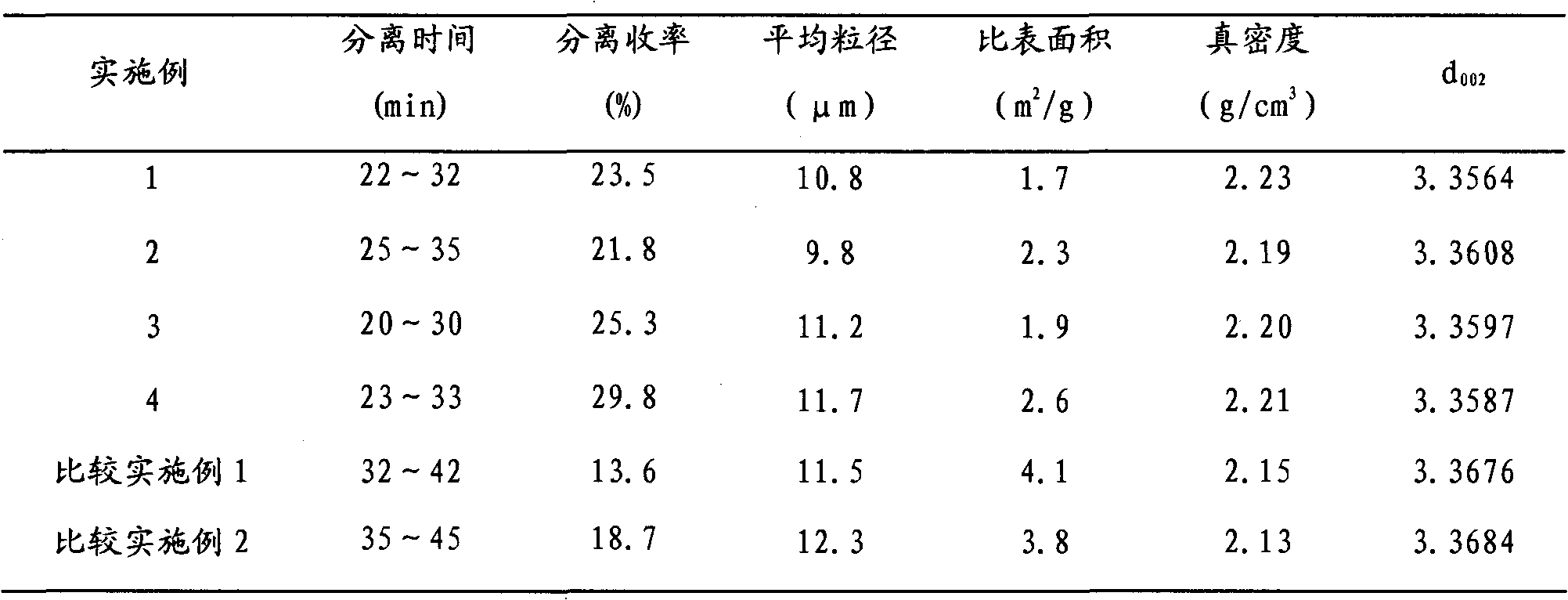

The technical problem to be solved by the present invention is to overcome the defects of low separation efficiency of mesophase carbon microspheres, low product yield, large solvent consumption and high separation cost in the existing method for preparing mesophase carbon microspheres by thermal polymerization, and Provided is a separation method for preparing mesophase carbon microspheres by thermal polymerization and the mesophase carbon microsphere electrode material prepared therefrom

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Particle size distribution | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Login to View More

Abstract

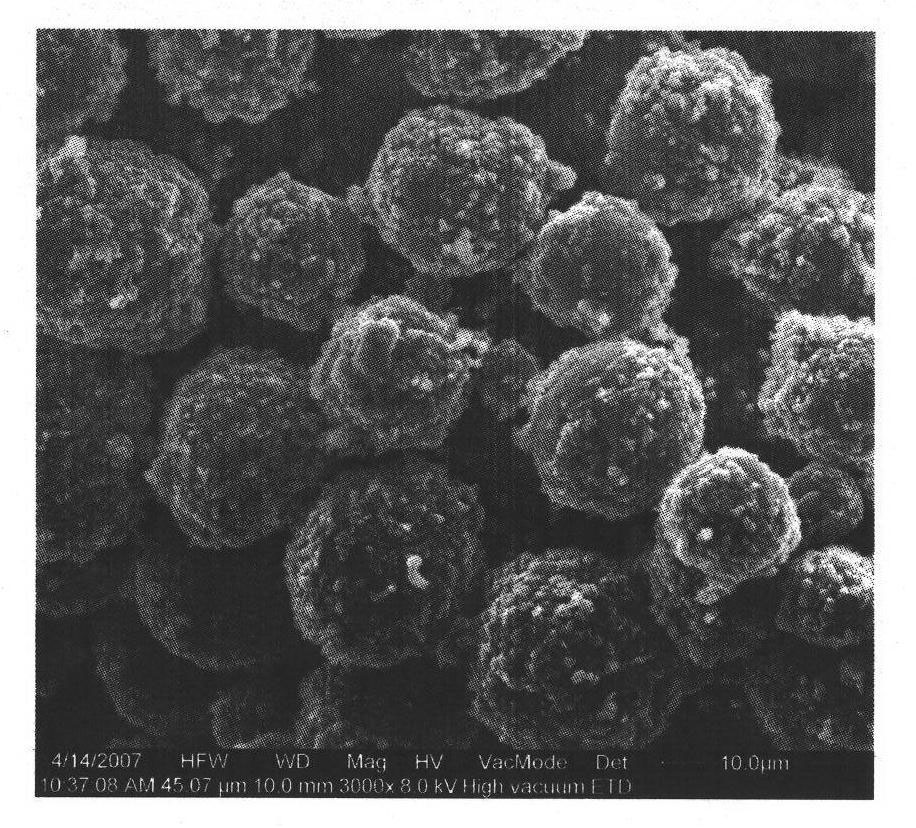

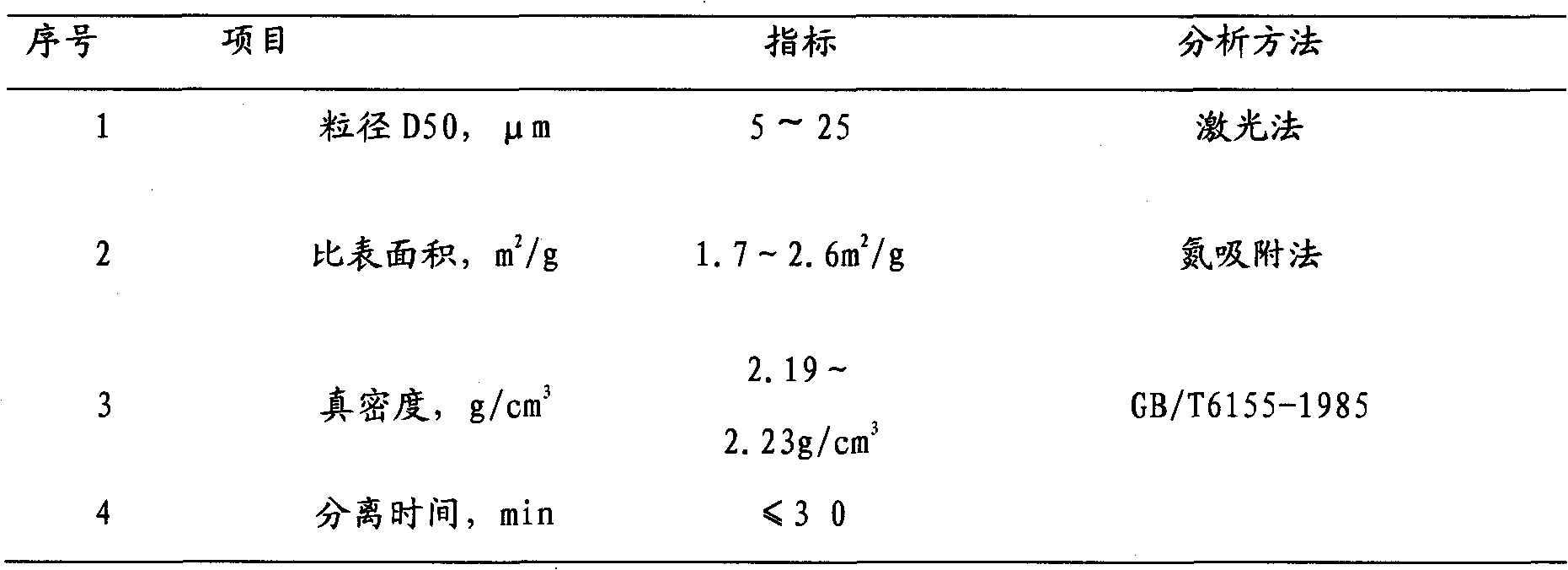

The invention discloses a preparation method of a mesocarbon microbead. The method comprises the following steps of: heating coal medium temperature pitch or coal modified pitch at the temperature rise speed of 60 to 300 DEG C / h in the protective nitrogen; heating the coal medium temperature pitch or the coal modified pitch with stirring to between 320 and 500 DEG C for polymerization to obtain a pitch polymerized mother liquid; stirring and mixing a solvent mixture of washing oil, light oil, kerosene or the mixture thereof and sodium dodecyl benzene sulfonate of an anion surface active agent, and the polymerized mother liquid, and filtering the mixture in vacuum; and further purifying the mixture to obtain a mesocarbon microbead product. Because the surface active agent is added into an extracting solvent in the process of purification, the method reduces viscosity of parent phase pitch of the carbon-containing microbead, improves separation efficiency of the mesophase microbead, and ensures that the obtained mesocarbon microbead product has narrow particle size distribution; the particle size range of the product is 1 to 30 mu m, and the product has good sphericity, and the specific surface area of 1.7 to 3.5 m<2> / g; moreover, the method is simple and convenient, raw materials are readily available and have low cost.

Description

technical field The invention specifically relates to a preparation method of mesophase carbon microspheres. Background technique Mesophase carbon microspheres (MCMB) are another new material with great development potential and application prospects after mesophase pitch-based needle coke and carbon fiber. Due to the high electrical conductivity, thermal conductivity and Surface activity, if mesophase carbon microspheres with specific size and good structural orientation can be further prepared cheaply and efficiently, it can be widely used in industries such as machinery industry, nuclear energy industry, chemical industry, semiconductor industry, new energy , environmental protection and other fields. The yield and quality of MCMB finished products in production are still the key issues to determine its cost. Therefore, effectively controlling the growth of mesophase carbon microspheres, increasing the yield of MCMB products in industrial production, and reducing the p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01B31/02

Inventor 张琢郑义周益竹陈锟高楠

Owner SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com