Process for preparing hihg-quality diesel oil or jet fuel maximumly from coal liquefied oil

A technology for coal liquefied oil and jet fuel, which is applied in the petroleum industry, refined hydrocarbon oil, etc., can solve the problems of high total pressure, high cetane number, and harsh hydrorefining process conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

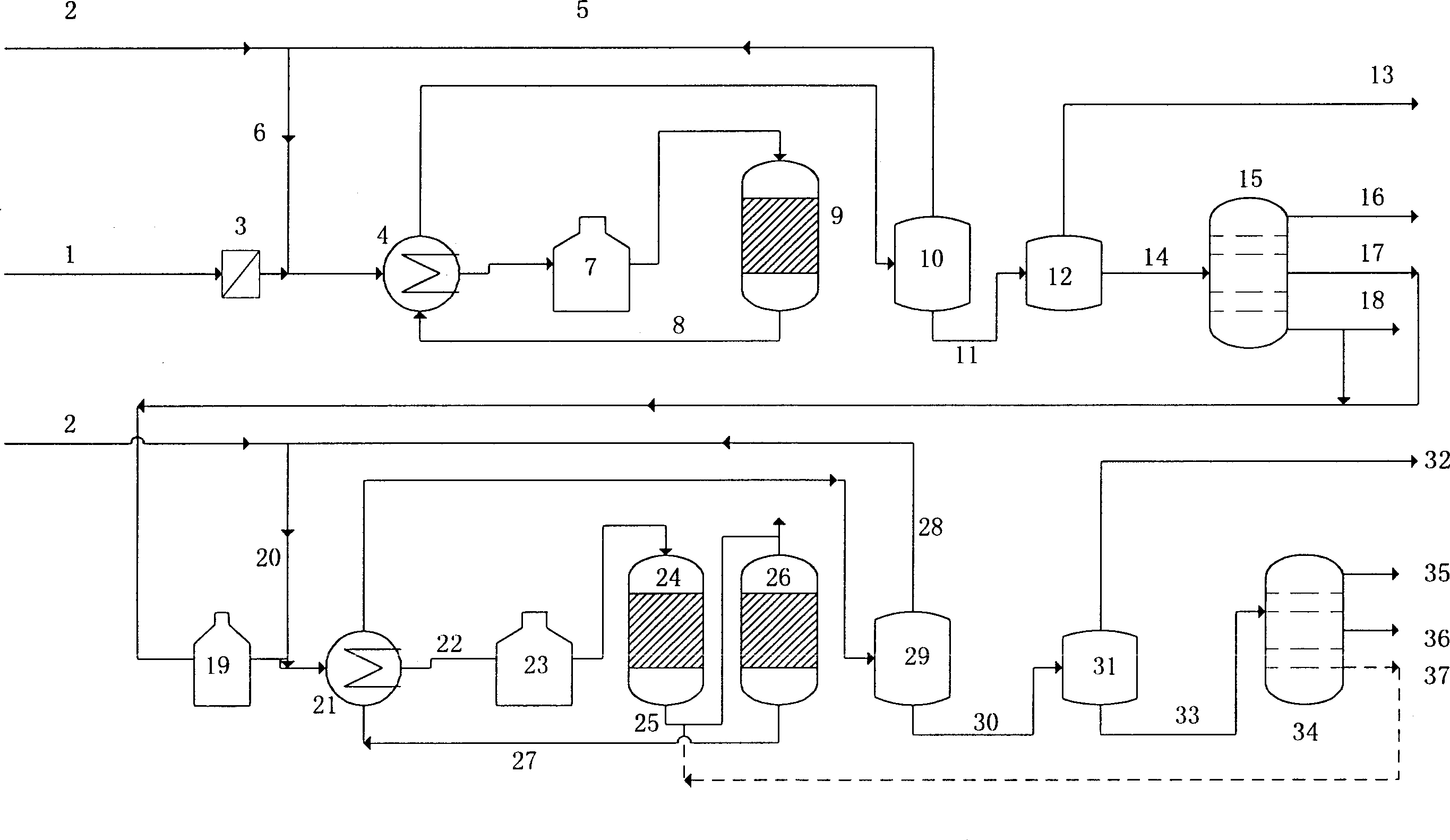

[0033] The filtered coal liquefied oil A and hydrogen enter the stable hydrogenation reactor, contact with the hydrogenation protection agent RG-10A / RG-10B, and the hydrogenation refining catalyst RCT-1, and the effluent of the stable hydrogenation reactor is separated to obtain gas, Naphtha fraction, diesel fraction and tail oil fraction, among which part of the tail oil fraction is recycled back to the coal liquefaction system as a hydrogen donor, and the hydrogen-rich gas stream is recycled back to the stable hydrogenation reactor; the diesel fraction obtained from the stable hydrogenation reactor, the remaining The tail oil fraction and hydrogen enter the deep hydro-upgrading reactor equipped with hydrofinishing agent RN-10 and hydrocracking agent RT-5, contact with RN-10 and RT-5, and separate the hydro-upgrading reactor The effluent is obtained from gas, naphtha fraction, diesel fraction and tail oil fraction. The tail oil fraction is returned to the deep hydro-upgrading ...

Embodiment 2

[0036] The process of this embodiment is basically the same as that of Embodiment 1, the raw material is still coal liquefied oil A, and the final target product is jet fuel. The process conditions and jet fuel product properties of stable hydrogenation and deep hydroupgrading are listed in Table 2 and Table 3, respectively. As can be seen from Table 3, the total yield of jet fuel has reached 50%, and the content of sulfur and nitrogen in the jet fuel fraction in the product is very low, and the indicators such as freezing point, aromatics content and smoke point have reached the requirements, and it is a qualified jet fuel product .

Embodiment 3

[0038] The process of this example is basically the same as that of Example 1, the raw material is still coal liquefied oil B, the final target product is diesel oil, and the deep hydro-upgrading process is one-pass, hydrofinishing agent RN-10 and hydrocracking agent RT -5 were packed in two reactors respectively. The properties of feedstock oil, process conditions and properties of diesel products are listed in Table 1, Table 4 and Table 5, respectively. It can be seen from Table 1 that the coal liquefied oil B is relatively heavy; it can be seen from Table 5 that the total yield of diesel oil is 73%, which realizes the purpose of producing diesel oil in a large amount. The content of sulfur and nitrogen in the diesel fraction is very low, and the content of aromatics is low, which can meet the requirements for sulfur, nitrogen and aromatics content of Class III diesel in the "World Fuel Specifications". The cetane number exceeds 45, which is a qualified diesel product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com