Coal tar whole fraction hydrotreatment process

A technology for hydroprocessing and coal tar, which is applied in the fields of hydroprocessing process, petroleum industry, and hydrocarbon oil treatment, etc. It can solve the problems of bed blockage, complex process, large amount of catalyst, etc., so as to reduce the cost of equipment and operation, simplify The effect of process flow and long operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

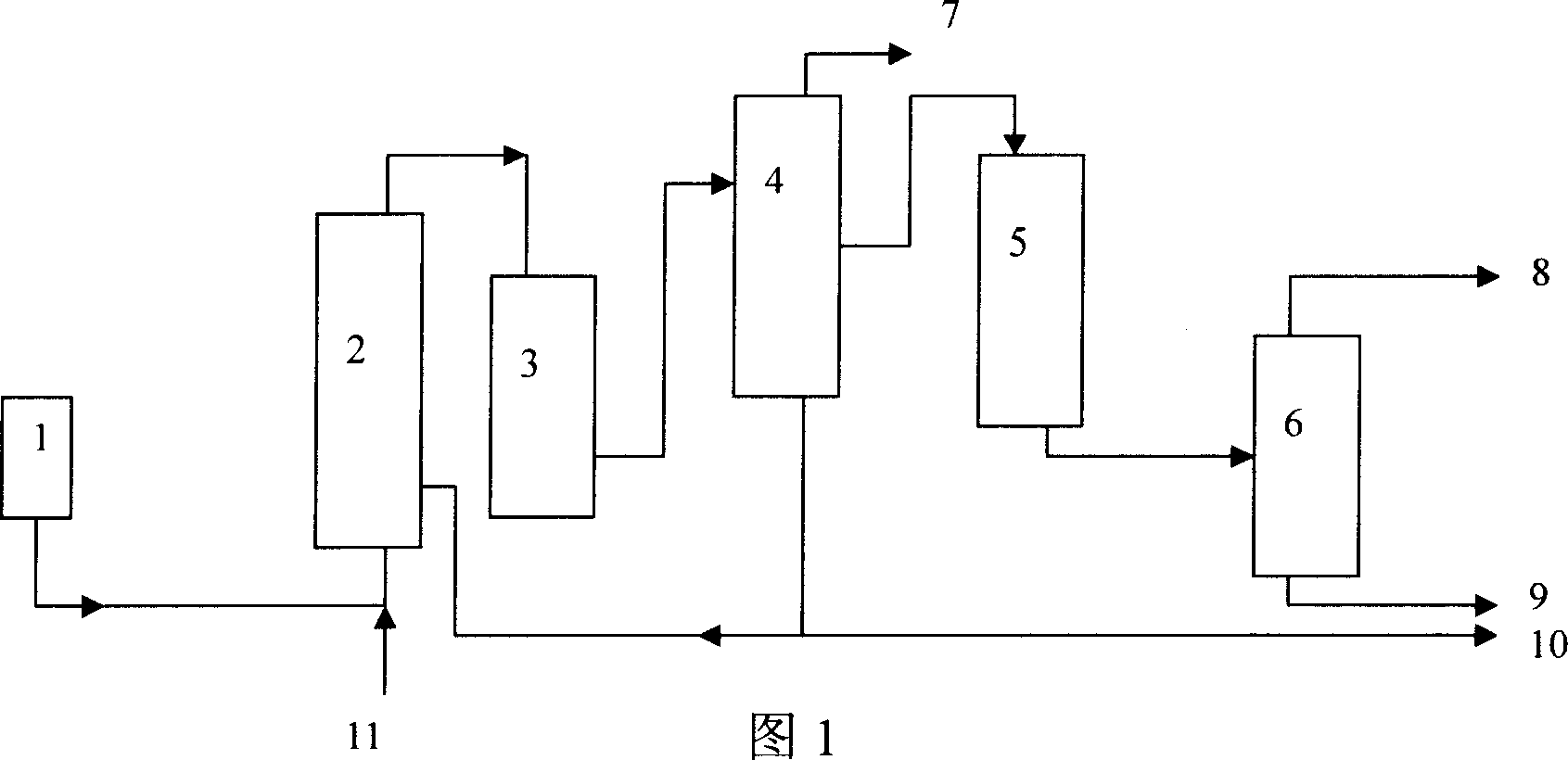

[0027] This example is a test of treating the whole fraction of coal tar by adopting the combined process of suspension bed hydrogenation and fixed bed hydrofining. The specific operation process is shown in Figure 1. The residual oil or residual oil in the raw material tank 1 is mixed with the mixed feed prepared by a homogeneous catalyst in a certain proportion and hydrogen 11, and then enters the suspension bed reactor 2, and the flow from the bottom of the suspension bed reactor flows through the settling tank 3 and enters Distillation unit 4 cuts out water 7, light oil fraction 370°C. Among them, the light oil fraction of 370°C to the discharge device, and the rest circulates back to the suspension bed reactor 2 . Test conditions and results are shown in Table 2, and product properties are shown in Table 3. The suspended bed catalyst used is water-soluble nickel phosphomolybdate. The composition and properties of the hydrogenation refining catalyst are as follows: it co...

Embodiment 4

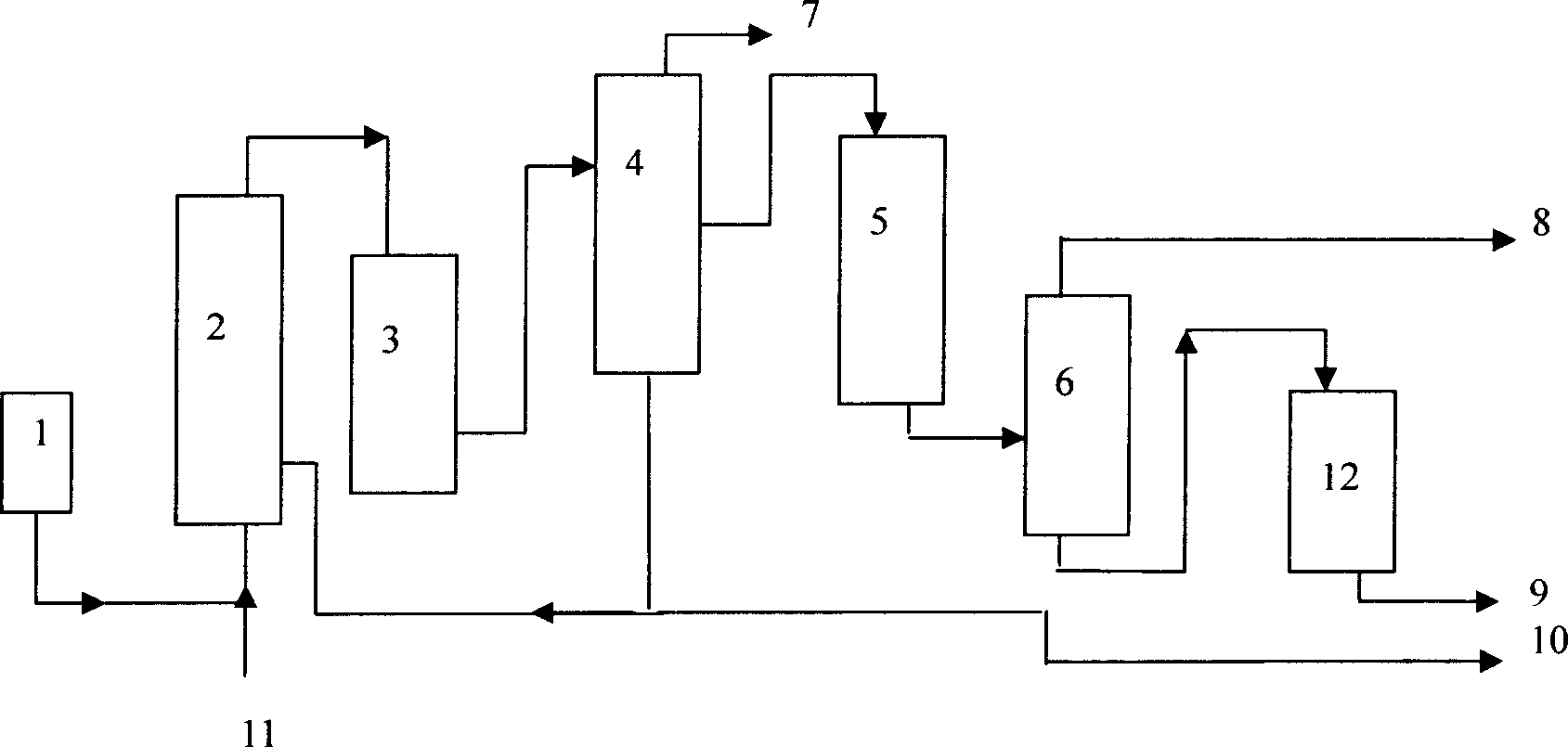

[0029] The combined process of suspended bed and fixed bed hydrofining and deep dearomatization treats the whole fraction of coal tar, and the diesel oil produced can meet the national standards. See attached for specific operation procedure figure 2 , which is basically the same as that of accompanying drawing 1, except that the 150-370°C diesel oil fraction from the distillation unit 6 enters the fixed-bed dearomatization reactor 12 for deep dearomatization reaction. The properties of the hydrotreating catalyst are the same as in Example 1. The composition and properties of the dearomatization catalyst are as follows: 25% tungsten oxide, 5% nickel oxide, and the carrier is alumina containing 10% silica. The pore volume of the catalyst is 0.35ml / g, and the specific surface area is 200m 2 / g. Reaction conditions and results are shown in Table 4, and product properties are shown in Table 5.

[0030] project

[0031] Numbering

[0032] Exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com