Coal water slurry additive

An additive and coal-water slurry technology, which is applied in fuel additives, petroleum industry, liquid carbon-containing fuels, etc., can solve the problems of large dosage, limited application, limited universality, etc., and achieve good slurrying properties, good adaptability, The effect of using less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

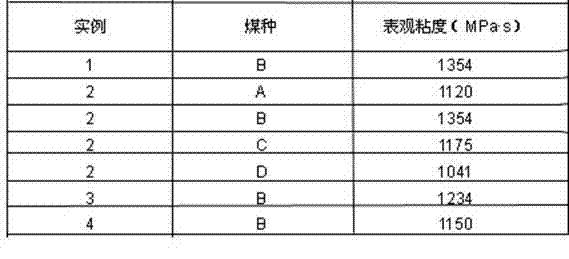

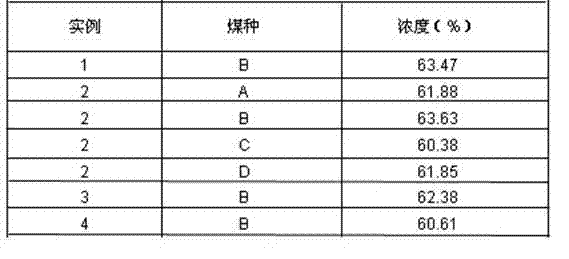

Examples

preparation example Construction

[0023] The preparation method of described additive is as follows:

[0024] Raw materials: β-naphthalenesulfonic acid formaldehyde polycondensate prepared according to traditional methods

[0025] Sodium lignosulfonate, penetrant sodium alkylsulfonate, and emulsifier are all purchased from the market

[0026] At 70°C, stir and dissolve β-naphthalenesulfonic acid formaldehyde polycondensate and sodium lignosulfonate in water, then add penetrant and emulsifier, and stir evenly.

Embodiment (1)

[0028] The weight ratio of β-naphthalenesulfonic acid formaldehyde polycondensate, sodium lignosulfonate, penetrant and emulsifier is 1:1.0-1.5:0.04-0.05:0.02-0.03. Compounded into additives according to the preparation method.

Embodiment (2)

[0030] The weight ratio of β-naphthalenesulfonic acid formaldehyde polycondensate, sodium lignosulfonate, penetrant and emulsifier is 1:0.5-0.9:0.01-0.02:0.02-0.03. Compounded into additives according to the preparation method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com