TA (tannic acid) modifying additive and application to coal-water slurry preparation

A technology of tannic acid and additives, applied in the field of additives and new additives of coal-water slurry, can solve the problems of no stabilization, difficult coal particle dispersion, etc., and achieve the effects of good market potential, low price and simple installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

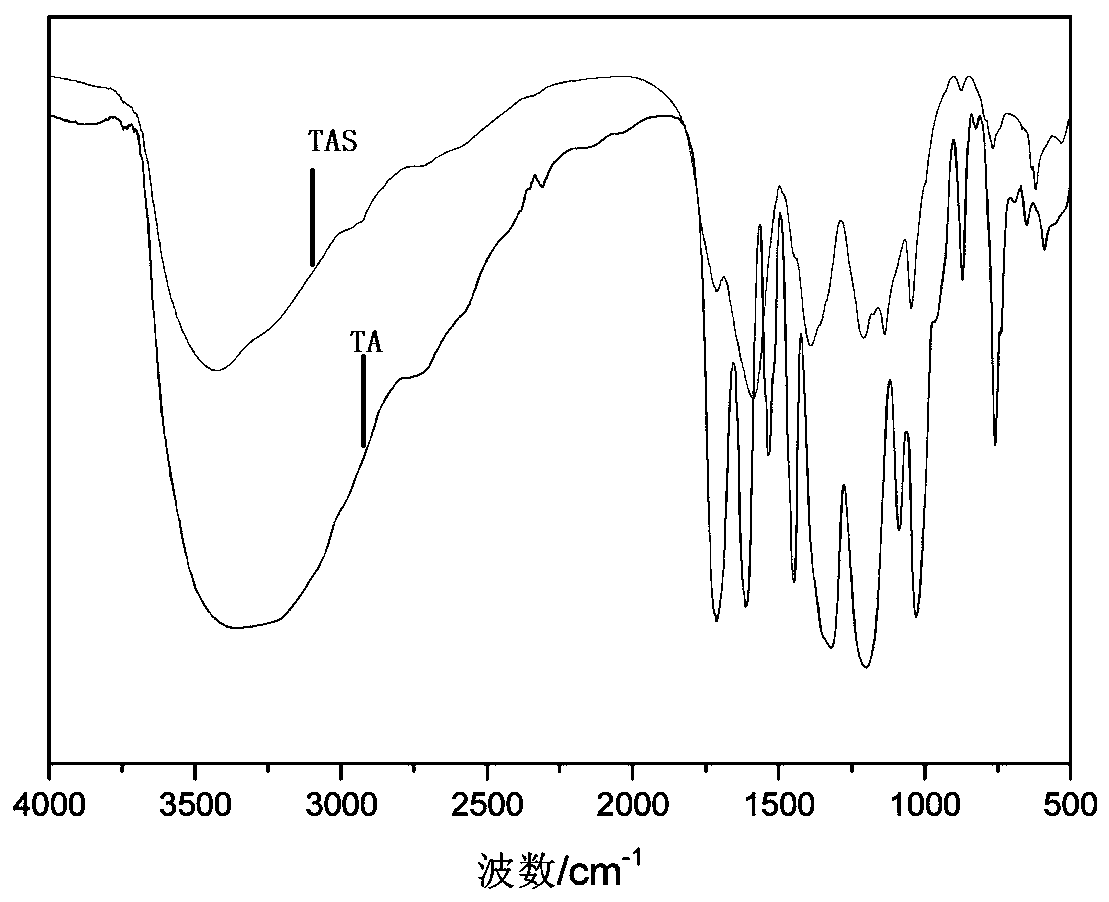

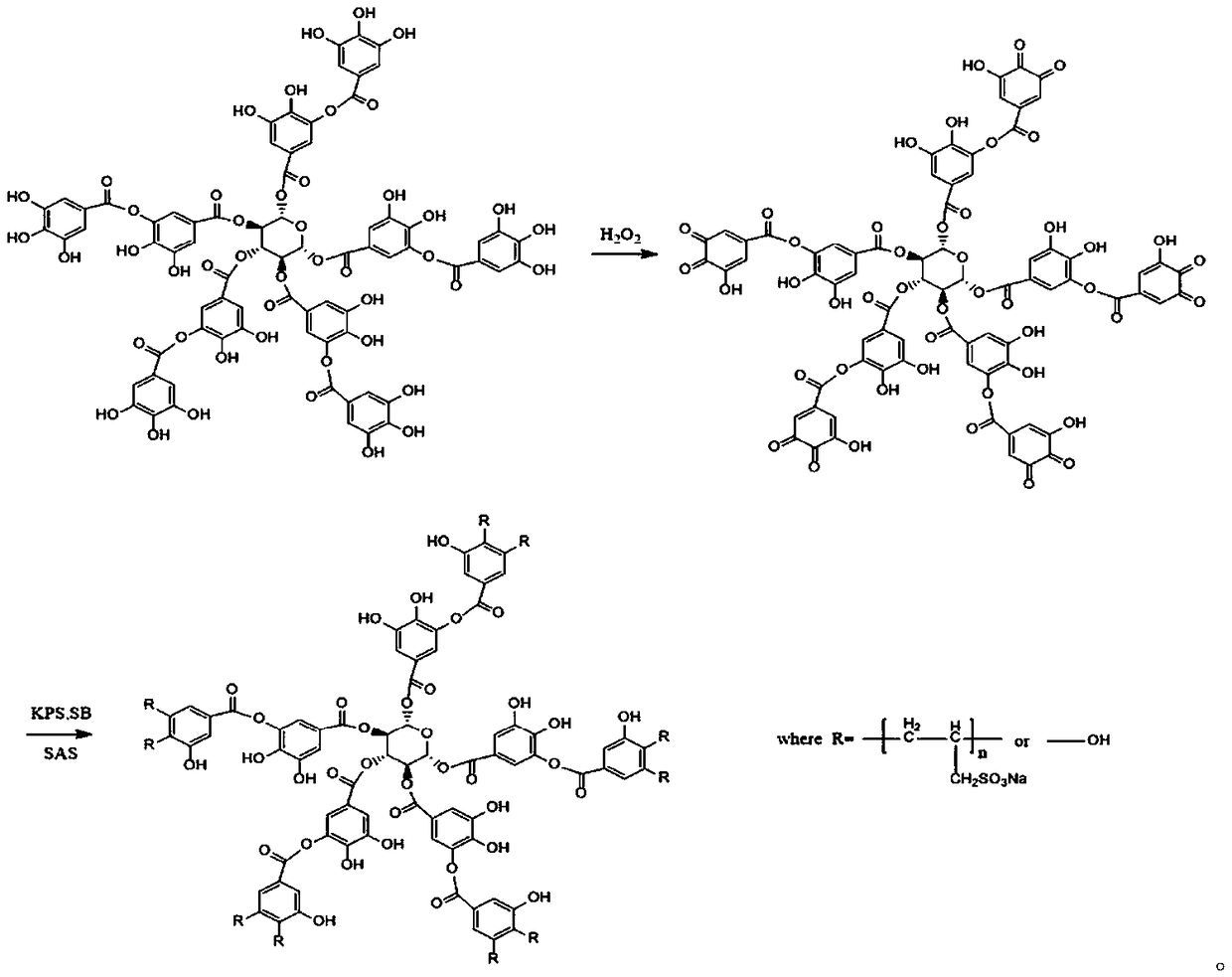

[0022] Get 100ml of distilled water and dissolve 10g of tannic acid in a 250ml three-neck flask equipped with two constant pressure dropping funnels, then add 20ml of 30% H 2 o 2 , put the three-neck flask into an oil bath, set the temperature to 75°C, and react at a stirring speed of 300r / min for 0.5h. Add 16.93gSAS, 0.8gKPS and 0.3gNaHSO from two dropping funnels 3 , The reaction time is 3h. After the reaction is over, stop heating and stirring, cool to normal temperature, neutralize the yellow-brown product to pH=9 and filter out water-insoluble impurities to obtain a brown-black modified tannic acid solution, which is distilled under reduced pressure and used The additive (TAS) was obtained after washing with ethanol three times and drying at room temperature.

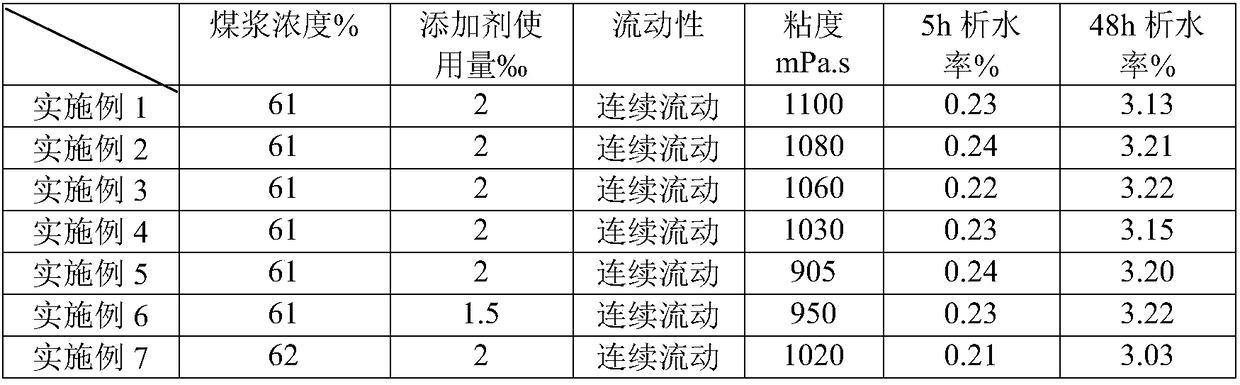

[0023] Performance test: Take a certain amount of pulverized coal from Shenyou No. 2 coal, use the amount of the above-mentioned additives as 0.2% of the mass of pulverized coal, and prepare a coal slurry with a...

Embodiment 2

[0027] Take 100ml of distilled water and dissolve 10g of tannic acid in a 250ml three-necked flask equipped with two constant pressure dropping funnels, then add a certain amount of 20ml of 30% H 2 o 2 , put the three-neck flask into an oil bath, set the temperature to 75°C, and react at a stirring speed of 300r / min for 0.5h. Add 12.76gSAS, 0.8gKPS and 0.3gNaHSO from two dropping funnels 3 , The reaction time is 3h. After the reaction is over, stop heating and stirring, cool to normal temperature, neutralize the yellow-brown product to pH=9 and filter out water-insoluble impurities to obtain a brown-black modified tannic acid solution, which is distilled under reduced pressure and used After washing with ethanol three times, the additive (TAS) was obtained after drying at normal temperature

[0028] According to the assay method of Example 1, the assay results are shown in Table 1.

Embodiment 3

[0030] Take 100ml of distilled water and dissolve 10g of tannic acid in a 250ml three-necked flask equipped with two constant pressure dropping funnels, then add a certain amount of 20ml of 30% H 2 o 2 , put the three-neck flask into an oil bath, set the temperature to 75°C, and react at a stirring speed of 300r / min for 0.5h. Add 8.47gSAS, 0.8gKPS and 0.3gNaHSO from two dropping funnels 3 , The reaction time is 3h. After the reaction is over, stop heating and stirring, cool to normal temperature, neutralize the yellow-brown product to pH=9 and filter out water-insoluble impurities to obtain a brown-black modified tannic acid solution, which is distilled under reduced pressure The additive (TAS) was obtained after washing with ethanol three times and drying at room temperature.

[0031] According to the assay method of Example 1, the assay results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com