Method for producing tar and hydrocarbon fuel products with coal

A technology for hydrocarbon fuel and tar, applied in the field of coal resource processing, can solve the problems of not being reasonably reflected, wasting coal, reducing the utilization efficiency of coal resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Embodiment 1: The present invention utilizes coal to produce tar and hydrocarbon fuel products

[0096] The implementation steps of this embodiment are as follows:

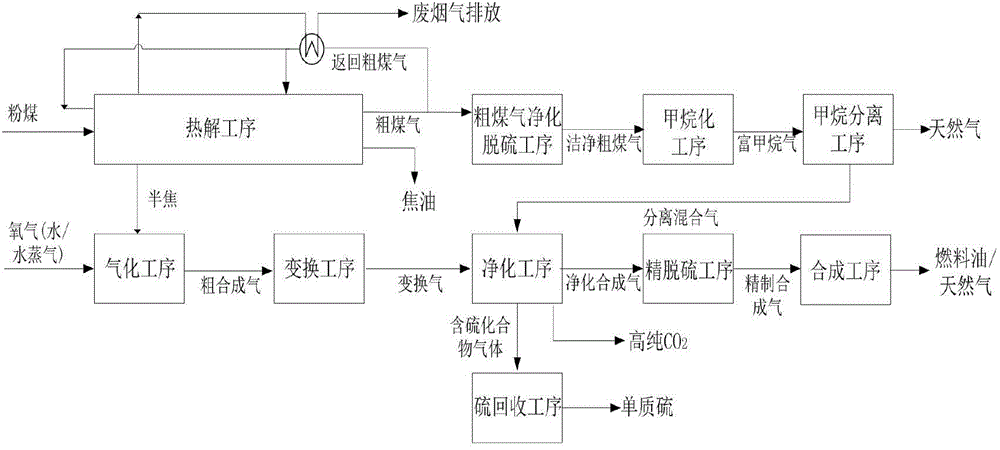

[0097] See attached for specific implementation steps figure 1 .

[0098] A long-flame coal in northern Shaanxi was used as raw material, and the methods specified in GB212-91 and GB476-91 were used for analysis. The results of the coal quality analysis are listed in Table 1.

[0099] The raw coal is ground to a particle size distribution of 100% by weight and less than 500 μm, wherein 55% is less than 125 μm, 40% is less than 75 μm, and 26% is less than 44 μm powder, and is transported to the heat sink through the feeding device according to the feeding amount of 5000kg / h. In the decomposition process, the pyrolysis reaction was carried out for 80 minutes at a temperature of 450 °C and an absolute pressure of 0.05 MPa. The resulting pyrolysis products are treated by the pyrolysis process internal dust r...

Embodiment 2

[0111] Embodiment 2: The present invention utilizes coal to produce tar and hydrocarbon fuel products

[0112] The implementation steps of this embodiment are the same as those of this embodiment, only some technical parameters are different.

[0113] Using the raw coal used in Example 1 as raw material, grind it to 100% less than 100 μm, and the particle size distribution is broken and freely distributed powder, and transport it to the pyrolysis process through the feeding device according to the feeding amount of 20t / h, at a temperature of 800 Under the conditions of ℃ and absolute pressure -0.05MPa, the pyrolysis reaction was carried out for 35min. Finally, the tar with a mass flow rate of 2135kg / h and a water content of 5% by weight, the semi-coke product with a mass flow rate of 13350kg / h and the volumetric flow rate of 4396m 3 / h of crude gas products, of which the pyrolysis crude gas used as heating fuel combustion is 2480m 3 / h.

[0114] The crude gas obtained from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com