Coal blending method suitable for coal for pressurizing gasification of Texaco water coal slurry

A technology of pressurized gasification and coal-water slurry, which is applied to the gasification of granular/powdered fuels, the manufacture of combustible gases, and the petroleum industry. Improve slurry performance and meet coal requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

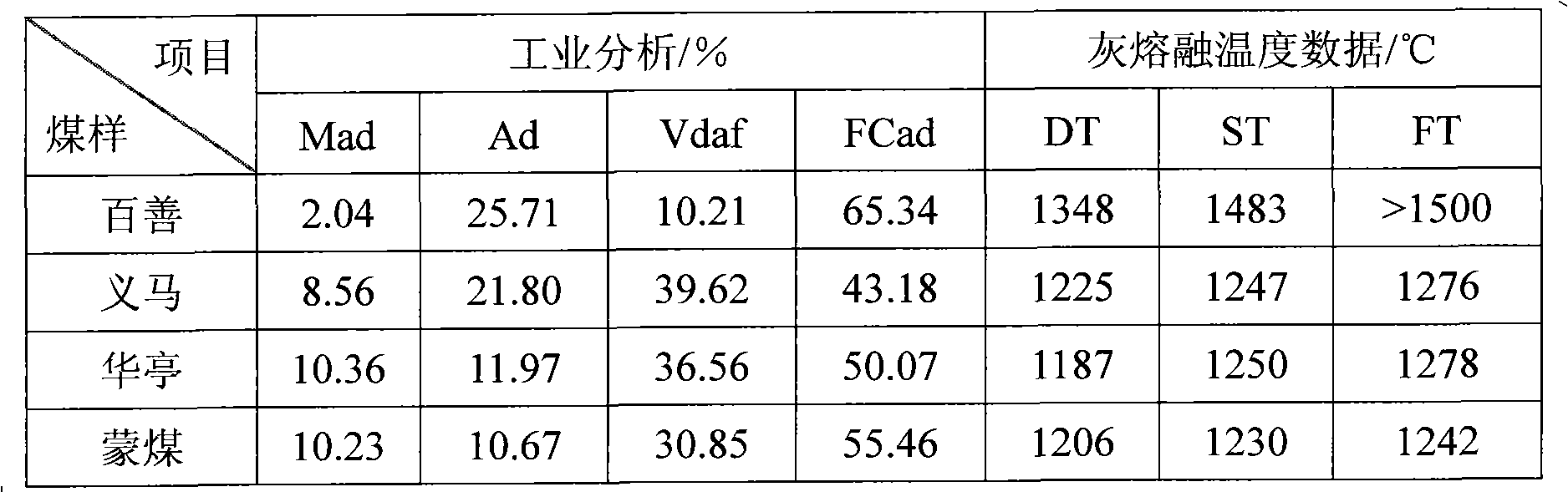

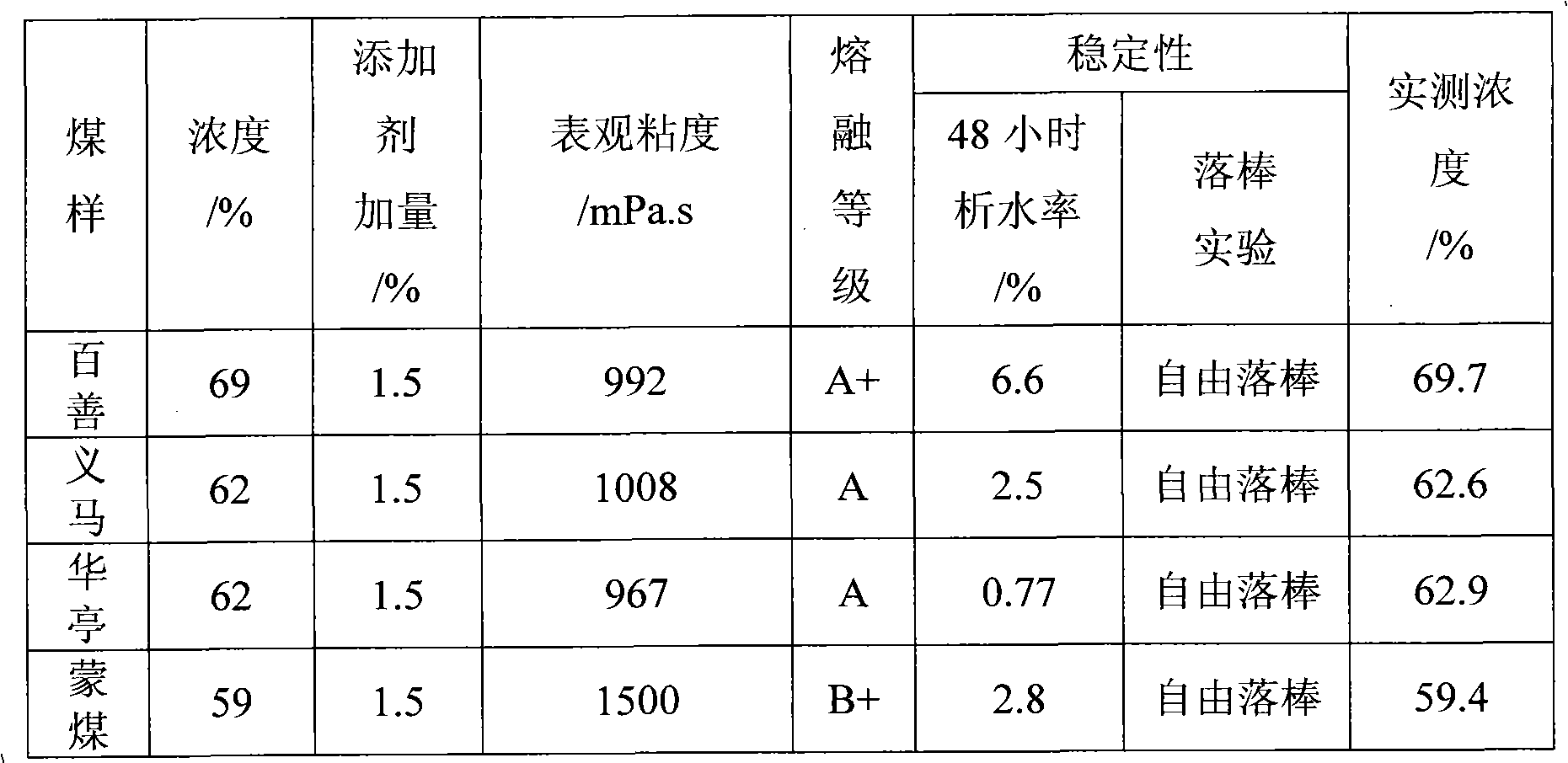

[0027] Take high ash melting temperature coal-Baishan coal, the coal blending ratio is 60%, low ash melting temperature coal-Yima coal, the coal blending ratio is 40%, and the blending is uniform. After analyzing the coal ash melting temperature DT, ST and FT are 1292°C, 1336°C, and 1370°C, respectively. Take high ash melting temperature coal-Baishan coal, the coal blending ratio is 50%, low ash melting temperature coal-Yima coal blending coal, the proportion is 50%, and the blending is uniform. After analyzing the coal ash melting temperature DT, ST and FT are 1271°C, 1306°C, and 1365°C, respectively. Take high-ash melting temperature coal-Baishan coal, the coal blending ratio is 40%, low-ash melting temperature coal-Yima coal, the coal blending ratio is 60%, and the blending is uniform. After analyzing the coal ash melting temperature DT, ST and FT are 1265°C, 1280°C, and 1358°C, respectively. Take high ash melting temperature coal-Baishan coal, the coal blending ratio is ...

Embodiment 2

[0029] Take high ash melting temperature coal-Baishan coal, the coal blending ratios are 60%, 50%, 40%, 30%, 20%, 10%, low ash melting temperature coal-Huating coal, the corresponding coal blending ratios are 40% %, 50%, 60%, 70%, 80%, 90%, evenly blended, the coal ash melting temperature after analysis is 1357°C, 1359°C, 1367°C, 1367°C, 1362°C, 1288°C. Take low-ash melting temperature coal-Huating raw coal to make coal-water slurry, and the concentration of the coal-water slurry made by it is 62%, take low-ash melting temperature coal-Huating coal, the coal blending ratio is 90%, and high-ash melting temperature coal-Baishan Coal, the proportion of coal blending is 10%, and the concentration of coal water slurry made after blending evenly is 66%. Take low-ash melting temperature coal-Huating coal with a coal blending ratio of 40%, and high-ash melting temperature coal-Baishan coal with a coal blending ratio of 60%. The concentration of the coal-water slurry made after blendin...

Embodiment 3

[0031] Take high ash melting temperature coal-Baishan coal, the coal blending ratios are 50%, 40%, 30%, 20%, 10% respectively, and low ash melting temperature coal-Mongolian coal, the coal blending ratios are 50%, 50%, 60%, 70%, 80%, 90%, evenly mixed, after analysis, the coal ash fusion temperature after coal blending is 1380°C, 1337°C, 1336°C, 1336°C, 1281°C. Take low ash melting temperature coal-Mongolian coal raw coal to make coal water slurry, the concentration of the coal water slurry made is 59%, take low ash melting temperature coal-Mongolian coal, the coal blending ratio is 90%, high ash melting temperature coal-100% Good coal, the coal blending ratio is 10%, and the concentration of the coal water slurry made after uniform blending is 63%. Take the low ash melting temperature coal-Mongolia coal, the coal blending ratio is 40%, and the high ash melting temperature coal-Baishan coal blending The proportion is 60%, and the concentration of the coal-water slurry made aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com