Method for preparing coal water slurry by modifying low-rank coal

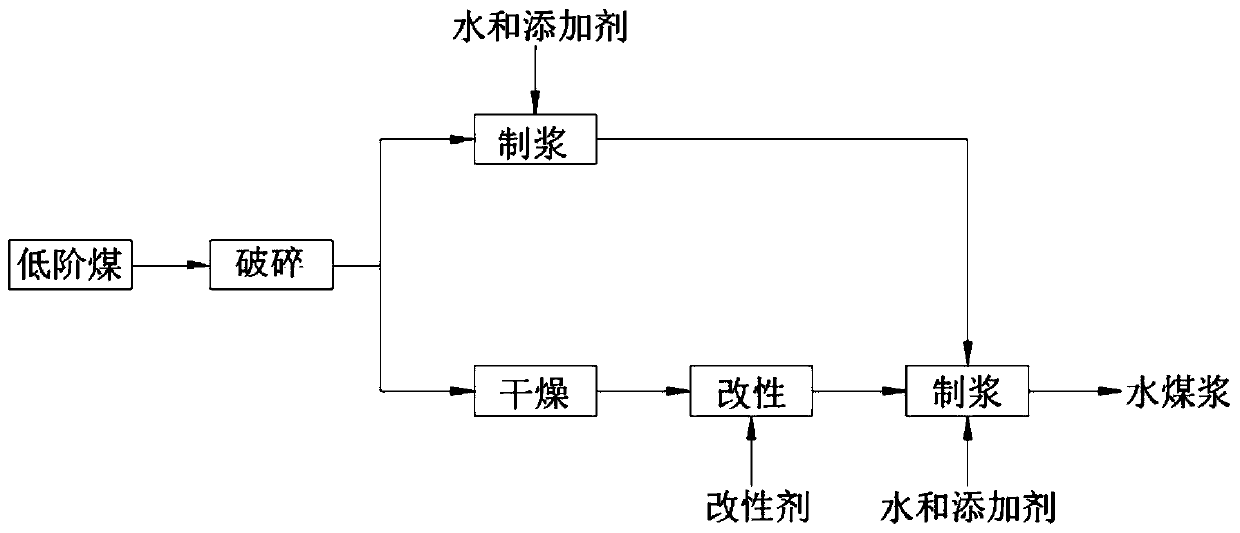

A low-rank coal and coal-water slurry technology is applied in the field of low-rank coal modification to prepare coal-water slurry, which can solve the problems of unfavorable slurry formation, large investment, and difficulty in producing high-concentration coal-water slurry, and achieve resource utilization value maximized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides a method for preparing coal-water slurry by modifying Xinjiang long-flame coal (full water is 18%, and the high calorific value of the water-containing ash-free base is 23MJ / kg), and the described method specifically includes the following steps:

[0049] (I) 117.07kg of Xinjiang long-flame coal was crushed by a hammer crusher until the average particle size was 6mm, and then divided into the first raw material and the second raw material according to the mass, wherein the mass of the first raw material was 11.82kg, and the mass of the second raw material It is 105.25kg. The first raw material, water and additives are finely ground and pulped in a vertical agitating fine mill to obtain a low-rank coal slurry. The mass ratio of the dry basis of the first raw material to the additive is 100:0.5, and the additive used is water content 3% sodium lignosulfonate, the mass percentage of the prepared low-rank coal slurry is 35.5%, the average particle s...

Embodiment 2

[0054] This embodiment provides a method for preparing coal-water slurry by modifying Inner Mongolian lignite (33% of total water, hydrated and ash-free base with a high calorific value of 19MJ / kg), and the method specifically includes the following steps:

[0055] (I) 129.16kg of low-rank coal is crushed by double rollers until the average particle size is 8mm, and then divided into the first raw material and the second raw material according to the mass, wherein the mass of the first raw material is 90.45kg, and the mass of the second raw material is 38.71kg . The first raw material, water and additives are finely ground and pulped in a vertical agitating fine mill to obtain a low-rank coal slurry. The mass ratio of the dry basis of the first raw material to the additive is 100:0.35, and the additive used is water content 9% naphthalenesulfonic acid formaldehyde condensate, the mass percentage of the prepared low-rank coal slurry is 50%, the average particle size of the low-...

Embodiment 3

[0060] This embodiment provides a method for preparing coal-water slurry by modifying Ningxia non-stick coal (full water is 20%, and the high-level calorific value of the water-containing ash-free base is 22MJ / kg). The method specifically includes the following steps:

[0061] (I) 126.9kg of low-rank coal is crushed by a hammer crusher to an average particle size of 5 mm and then divided into the first raw material and the second raw material by mass, wherein the mass of the first raw material is 25.35 kg, and the mass of the second raw material is 101.55 kg kg. The first raw material, water and additives are finely ground and pulped in a vertical agitating fine mill to obtain a low-rank coal slurry. The mass ratio of the dry basis of the first raw material to the additive is 100:0.2, and the additive used is naphthalenesulfonate Acid-formaldehyde condensate, the mass percentage of the prepared low-rank coal slurry is 40%, the average particle size of the low-rank coal slurry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com