Coal water slurry, preparation method thereof and preparation method of synthesis gas

A coal-water slurry and slurry technology, which is used in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of uneven particle size distribution, low hydrogen yield of synthesis gas, and low slurry concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] As previously mentioned, the first aspect of the present invention provides a kind of preparation method of coal-water slurry, this method comprises:

[0015] (1) Coal, water, additives, slag wax are mixed to obtain a slurry, and then the slurry is ground and sieved to obtain a primary slurry, and the primary slurry is divided into coal-water slurry A, coal-water slurry B and Coal water slurry C;

[0016] (2) The first grinding of the coal-water slurry A is carried out to obtain the slurry A, and the second grinding of the coal-water slurry B is carried out to obtain the slurry B; the slurry A and the slurry B are mixed with the water described in step (1) The coal slurry C is mixed to obtain the final coal water slurry.

[0017] The preparation method of the coal-water slurry of the present invention can be summarized as first mixing coal, water, additives, and slag wax, and then obtaining a primary slurry after grinding and sieving, and then returning a part of the p...

Embodiment approach

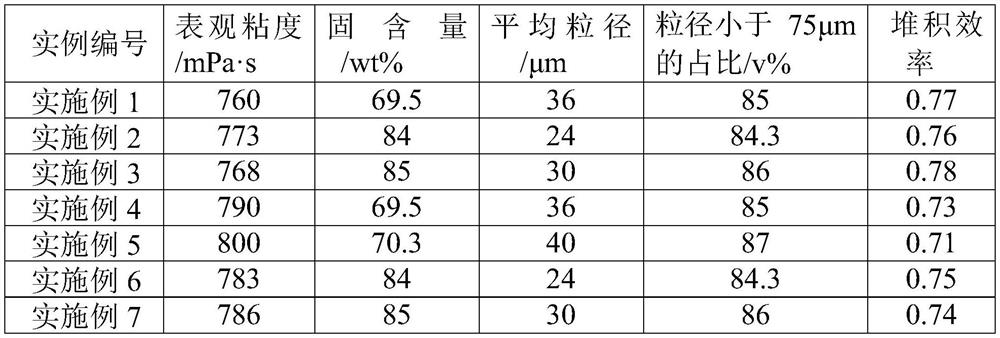

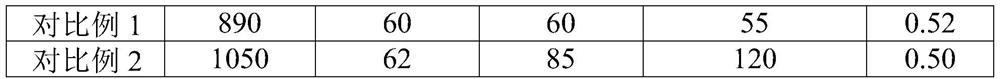

[0047] According to a preferred embodiment of the present invention, the apparent viscosity of the coal-water slurry is 760-800mPa·s, the solid content of the coal-water slurry is 65-85wt%, and the average particle size of the coal-water slurry is 20-40 μm, the stacking efficiency of the coal-water slurry is 0.7-0.8; the coal powder with a particle size of less than 75 μm in the coal-water slurry accounts for more than 80v% of the total coal powder. The coal-water slurry satisfying the above-mentioned range of performance parameters has better performance, and is more conducive to increasing the production rate of synthesis gas and hydrogen.

[0048] The third aspect of the present invention provides a method for preparing synthesis gas, the method comprising: mixing the coal-water slurry provided above in the present invention with oxygen for gasification reaction to obtain synthesis gas.

[0049] In some embodiments of the present invention, preferably, the volume ratio of t...

Embodiment 1

[0066] (1) The Meihuajing coal is crushed to obtain coal powder with a particle size of 7 mm;

[0067] (2) the coal powder, water, additive (comprising 40wt% cetyltrimethylammonium bromide, 30wt% sodium dodecylbenzenesulfonate and 30wt% sodium carboxymethylcellulose) , Slag Wax 1 is kneaded according to the mass ratio of 50:19.9:0.1:30 to obtain slurry, then the slurry is ground in a high-speed grinder (rotating speed is 120r / min), and sieved through a 10-mesh sieve , to obtain primary slurry, the primary slurry is divided into coal water slurry A, coal water slurry B and coal water slurry C;

[0068] (3) Carry out the first grinding of the coal-water slurry A in the vertical stirring mill to obtain a slurry A with an average particle diameter of 25 μm, and carry out the second grinding of the coal-water slurry B in the vertical stirring mill to obtain the average particle size Diameter is the slurry B of 10 μm, wherein, based on the total amount of the primary slurry, the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com