Method for preparing coal water slurry from sludge and gasified fine ash

A technology of coal-water slurry and fine ash, which is applied in the field of solid waste resource utilization, can solve the problems of small processing capacity, low concentration of sludge and gasification fine ash in mixing pulp, high water content, etc. Significant economic and environmental benefits, and the effect of preventing the concentration of coal-water slurry from decreasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

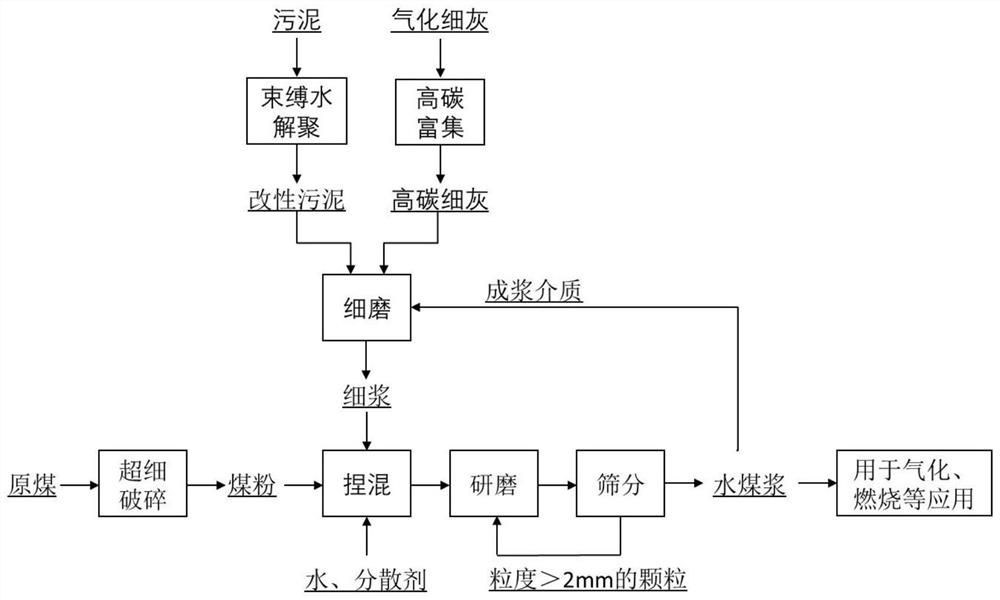

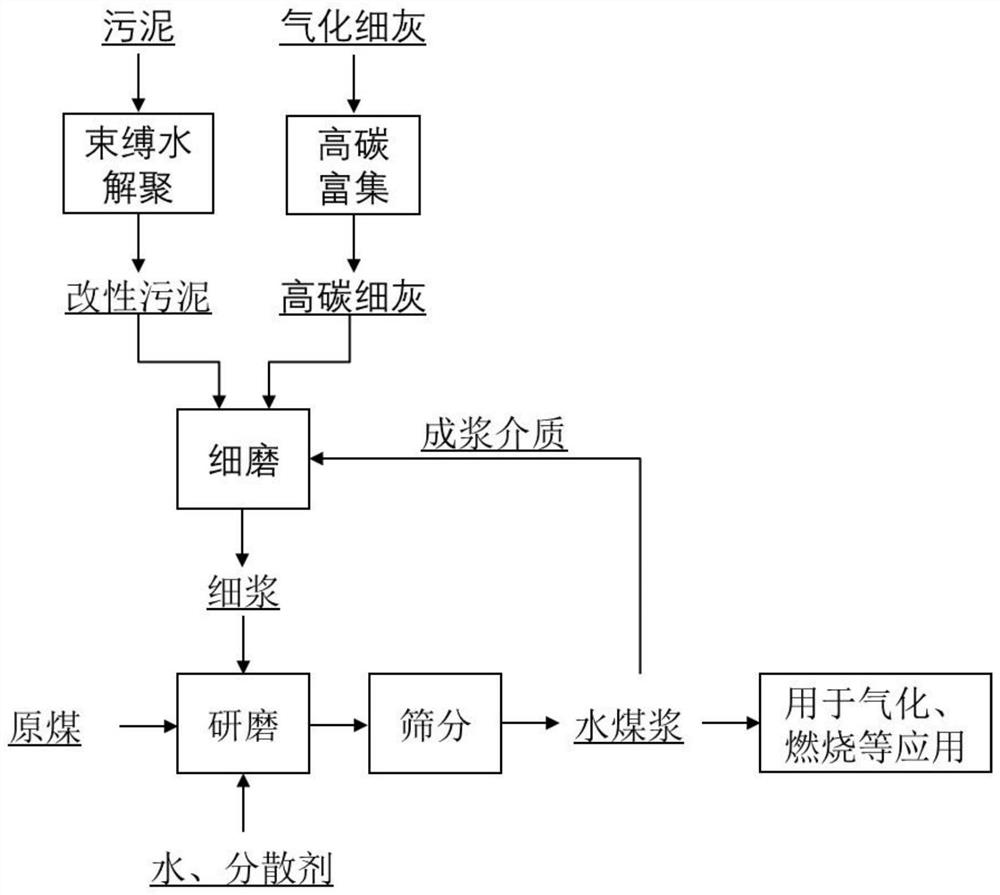

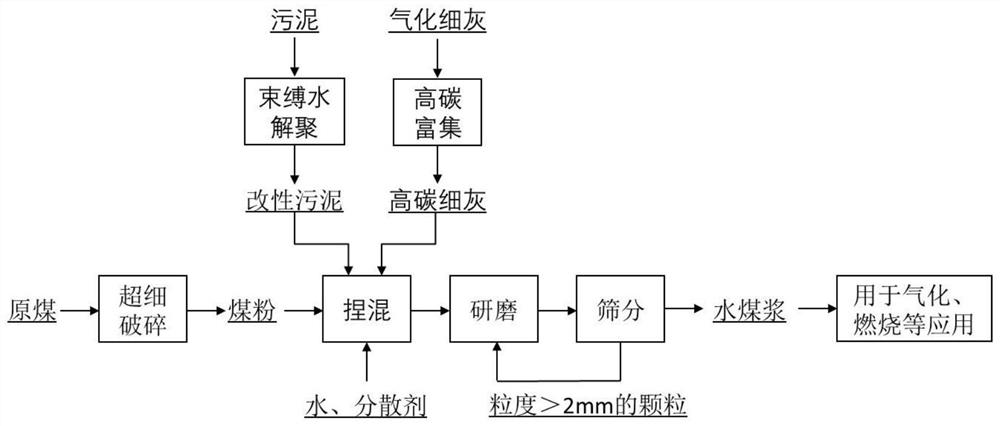

[0058] This embodiment provides a kind of method that utilizes sludge and gasification fine ash to prepare coal-water slurry, such as figure 1 As shown, the method includes the following steps:

[0059] (1) During the production process of the entrained bed GE coal-water slurry gasification to olefins plant, the 1.4t / h chemical sludge produced is mixed with 9t / h municipal sludge to obtain sludge with a water content of 70%. After 160°C Heated for 1.5h to depolymerize bound water to obtain modified sludge with a viscosity of 1196mP·s; the resulting 22.5t / h gasified fine ash with a dry basis carbon content of 55wt% was sieved for high-carbon enrichment to obtain 9.4 t / h high-carbon fine ash with a moisture content of 60% and a carbon content of 85% by weight on a dry basis;

[0060] Finely grinding the slurry-forming medium with the modified sludge and the high-carbon fine ash to obtain a fine slurry, and the solid particles in the fine slurry have a particle size of 0.01-25 μm...

Embodiment 2

[0064] This embodiment provides a kind of method that utilizes sludge and gasification fine ash to prepare coal-water slurry, such as figure 1 As shown, the method includes the following steps:

[0065] (1) During the production process of the natural gas plant prepared by fixed-bed coal gasification, 12.1t / h of chemical sludge with a water content of 50% is produced, and sodium hydroxide solid is added to the chemical sludge to control the proportion of sodium hydroxide to the chemical sludge. 5wt% of the dry basis of the sludge, heated at 180°C for 1h for bound hydrolysis to obtain a modified sludge with a viscosity of 1445mP s; the gasified fine ash with a carbon content of 38wt% on a dry basis was produced by hydrocyclone+ Sieve for high carbon enrichment to obtain 20.2t / h high carbon fine ash with dry basis carbon content of 73wt% and moisture content of 70%;

[0066] Finely grinding the slurry-forming medium with the modified sludge and the high-carbon fine ash to obtai...

Embodiment 3

[0070] This embodiment provides a kind of method that utilizes sludge and gasification fine ash to prepare coal-water slurry, such as figure 1 As shown, the method includes the following steps:

[0071](1) In the production process of the oil product factory produced by entrained bed multi-nozzle coal water slurry gasification, produce 6.6t / h chemical sludge with a moisture content of 90%, add sodium hydroxide solid in the chemical sludge, control Sodium hydroxide accounts for 10wt% of the dry basis of chemical sludge. Stir at room temperature for 6 hours to carry out bound hydrolysis to obtain modified sludge with a viscosity of 287mP s; the gasified fine ash with a carbon content of 30wt% on a dry basis is produced by using High-carbon enrichment by electro-selection to obtain 3.3t / h high-carbon fine ash with a moisture content of 80% and a carbon content of 70wt% on a dry basis;

[0072] Finely grinding the slurry-forming medium with the modified sludge and the high-carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com