A kind of environment-friendly coal-water slurry additive for low-rank coal pulping and preparation method thereof

An environmentally friendly, coal-water slurry technology, applied in the field of coal chemical industry, can solve the problems of low slurry concentration and difficulty in slurry formation, and achieve high slurry concentration, excellent fluidity and stability, and mild sulfonation reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

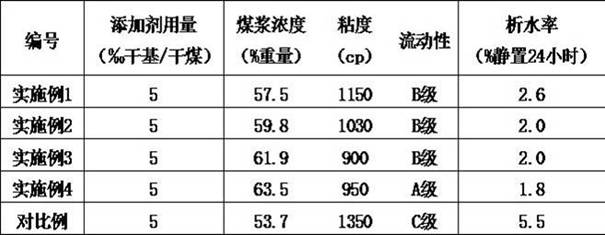

Examples

Embodiment 1

[0025] A preparation method for an environment-friendly coal-water slurry additive for low-rank coal slurrying, comprising the following steps:

[0026] The following parts are all parts by mass,

[0027] A. Preheat the reaction device to 90°C, add 1.3 parts of industrial naphthalene, heat to 130°C, stir evenly, and gradually add 1.6 parts of concentrated sulfuric acid dropwise;

[0028] B. Add 0.6 parts of water, adjust the acidity to 28%, and control the temperature at 120°C;

[0029] C. Add 0.14 parts of styrenesulfonic acid and 0.14 parts of acrylate, stir evenly, and gradually add 0.8 parts of formaldehyde dropwise;

[0030] D. Add alkali to neutralize to a pH value of 11, add water to cool to room temperature, and obtain a methylene naphthalene sulfonate-styrene sulfonate-acrylate polymer condensation material with a concentration of 40wt%, for subsequent use;

[0031] E. Add lignosulfonate to the mixing device for stirring, then add methylene naphthalene sulfonate-sty...

Embodiment 2

[0037] This embodiment is improved on the basis of Embodiment 1.

[0038] In step A, after the industrial naphthalene is added and the industrial naphthalene is melted, a pretreatment gas is introduced into the industrial naphthalene. The pretreatment gas contains 30wt% sulfur trioxide and 70wt% nitrogen, and the temperature is maintained at 90°C for 30 minutes.

[0039] In this example, prior to the high-temperature sulfonation reaction using concentrated sulfuric acid, low-temperature sulfonation pretreatment was performed on industrial naphthalene with sulfur trioxide. Since the low-temperature sulfonation process can reduce the combination number of sulfo groups and aromatic rings, thereby promoting the hydrolysis in step B.

Embodiment 3

[0041] This embodiment is improved on the basis of Embodiment 2.

[0042] In step B, the amount of water used for the reaction is continuously added linearly, and at the same time, the pressure is gradually increased in the reaction device, the pressure is 3.5-4.5 bar, and the rate of pressure increase is linearly related to the rate of water addition.

[0043] In this embodiment, by adopting the reaction method of high pressure hydrolysis, the reverse reaction of hydrolysis can be effectively reduced, and the pressure increases linearly with the addition of water, which can avoid the influence of pressure fluctuation on the balance of hydrolysis reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com