Sludge coal-water slurry and preparation method thereof

A technology of coal-water slurry and sludge water, which is applied in the field of sludge-coal-water slurry and its preparation, can solve the problems of increased pulping cost, excessive addition of dispersants and stabilizers, and achieve saving of pulping cost and fluidity Good, simple pulping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, prepare sludge coal-water slurry

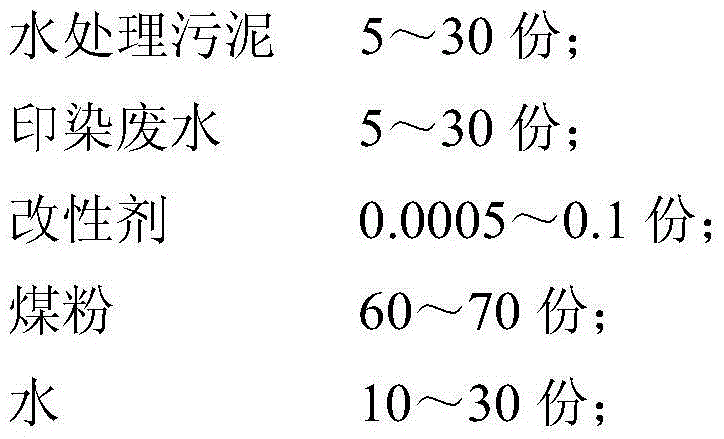

[0026] (1) Raw materials

[0027] Yanzhou coal powder (moderately metamorphic bituminous coal), analytical water 2.64%, ash content 6.29%, particle size less than 3mm;

[0028] The sludge produced by a sewage treatment plant in Shenzhen has a moisture content of about 70%;

[0029] Coal slurry dispersant: sodium lignosulfonate;

[0030] Modifier: a copolymer of humic acid and acrylic acid at 50°C;

[0031] (2) Preparation of coal water slurry

[0032] Mix 70 parts of sludge produced by a sewage treatment plant in Shenzhen, 30 parts of printing and dyeing wastewater (with a water content of 95%) and 0.003 parts of modifier, stir for 30 minutes under high shear conditions, and stand still for 1 hour to 3 days to obtain Modified sludge with better fluidity;

[0033] The modified sludge obtained by the above method, dispersant for coal slurry (sodium lignin sulfonate), Yanzhou coal powder and water are mixed and ground t...

Embodiment 2

[0036] Embodiment 2, prepare coal-water slurry

[0037] (1) Raw materials

[0038] Lu'an coal powder (lean and lean coal), total water 2.86%, ash content 10.71%, particle size less than 3mm;

[0039] The sludge produced by a sewage treatment plant in Shenzhen has a moisture content of about 70%;

[0040] Coal slurry dispersant: humate

[0041] Modifier: a copolymer of humic acid and acrylic acid at 100°C;

[0042] (2) Preparation of coal water slurry

[0043] Mix 80 parts of sludge produced by a sewage treatment plant in Shenzhen, 20 parts of printing and dyeing wastewater (with a water content of 95%) and 0.005 part of modifier, stir for 20 minutes under high shear conditions, and stand still for 1 hour to obtain a relatively fluidity Good modified sludge;

[0044] The modified sludge obtained above, Lu'an coal powder and water were mixed and ground to obtain a coal-water slurry with a concentration of 61.6%. Among them, the modified sludge, dispersant for coal slurry, L...

Embodiment 3

[0047] Embodiment 3, prepare coal-water slurry

[0048] (1) Raw materials

[0049] Lu'an coal powder, total water 2.86%, ash content 10.71%, particle size less than 3mm;

[0050] The sludge produced by a sewage treatment plant in Shenzhen has a moisture content of about 70%;

[0051] Dispersant for coal slurry: humate

[0052] Modifier: a copolymer of humic acid and acrylic acid at 100°C;

[0053] (2) Preparation of coal water slurry

[0054]Mix 50 parts of sludge produced by a sewage treatment plant in Shenzhen, 50 parts of printing and dyeing wastewater (with a water content of 95%) and 0.005 modifier, stir for 30 minutes under high shear conditions, and stand still for 30 minutes to obtain a fluid with good fluidity. Modified sludge;

[0055] Mix and grind the modified sludge and coal slurry obtained above with a dispersant (humate), Lu’an coal powder and water to obtain a coal-water slurry with a concentration of 63.8%. Among them, the modified sludge and coal slurry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com