Method for using sludge floccules decomposed by alkaline substances to promote slurry forming of sludge and coal-water slurry

An alkaline substance, sludge water technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc. The effect of improving quality and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

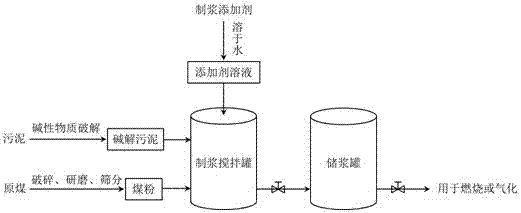

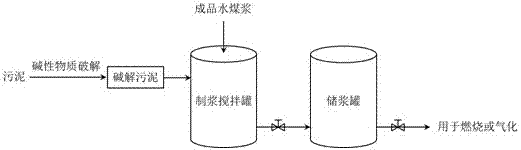

Method used

Image

Examples

Embodiment approach

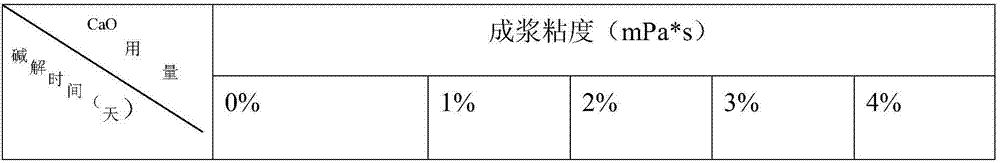

[0029] The sludge is taken from the mechanically dewatered sludge produced by a sewage treatment plant, with a moisture content of 80.76%, which is used for alkaline hydrolysis modification and subsequent sludge coal-water slurry production.

[0030] CaO powder is selected as the alkaline substance, and its dosage is respectively 0 (that is, original sludge), 1%, 2%, 3% and 4% of the sludge mass (converted according to the moisture content of 80%), and it is fully stirred for 20 minutes to ensure that the CaO powder Mix well with the sludge, and store the well-stirred sludge in a sealed plastic bottle to avoid loss of moisture. Alkaline hydrolysis time was 0 day (ie original sludge), 1 day and 3 days.

[0031] When making coal-water slurry from alkaline hydrolysis sludge, the mass ratio relationship of each raw material component is: sludge: dry coal powder = 15:100, additive: dry coal powder = 0.8:100 converted according to the moisture content of 80%. The additive is sodium...

Embodiment 2

[0039] (1) Implementation method

[0040] The sludge is taken from the mechanically dewatered sludge produced by a sewage treatment plant, with a moisture content of 82.42%, which is used for alkaline hydrolysis modification and subsequent sludge coal-water slurry production.

[0041] Alkaline substances choose NaOH and Ca(OH) 2, its dosage is 2% and 4% of the sludge mass (converted by 80% water content), fully stirred for 20 minutes, to ensure that the alkaline substance is mixed evenly with the sludge, and the uniformly stirred sludge is stored in a sealed plastic bottle. So as not to lose water, after 1 day (ie 24h) of treatment, alkali hydrolysis sludge was obtained. .

[0042] When making coal-water slurry from alkaline hydrolysis sludge, the mass ratio relationship of each raw material component is: sludge: dry coal powder = 15:100, additive: dry coal powder = 0.8:100 converted according to the moisture content of 80%. The additive is lignosulfonate. The solid mass c...

Embodiment 3

[0046] (1) Implementation method

[0047] The sludge is taken from the mechanically dewatered sludge produced by a sewage treatment plant, with a moisture content of 82.42%, which is used for alkaline hydrolysis modification and subsequent sludge coal-water slurry production.

[0048] Alkaline substances choose NaOH and Ca(OH) 2 , the dosage is 2% of the sludge mass (converted according to the moisture content of 80%), fully stirred for 20 minutes to ensure that the alkaline substance and the sludge are evenly mixed, and the evenly stirred sludge is stored in a sealed plastic bottle to avoid loss of moisture , After 1 day of treatment (ie 24h), the alkali hydrolysis sludge was obtained.

[0049] The coal-water slurry adopts the finished product prepared in advance, and the additive is naphthalenesulfonate formaldehyde condensate when making the coal-water slurry, and the mass ratio relationship between the additive and the dry coal powder is 0.8:100.

[0050] The alkali hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com