Paste filling material containing ultrafine tail mud as well as preparation method and application thereof

A paste filling and filling technology, which is applied in the field of building materials, can solve the problems such as difficulty in expropriating dumping sites for mining enterprises, reducing the number of tailings ponds used, and complex mineral components, achieving no metal leaching risk and reducing raw materials. cost, the effect of improving the recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

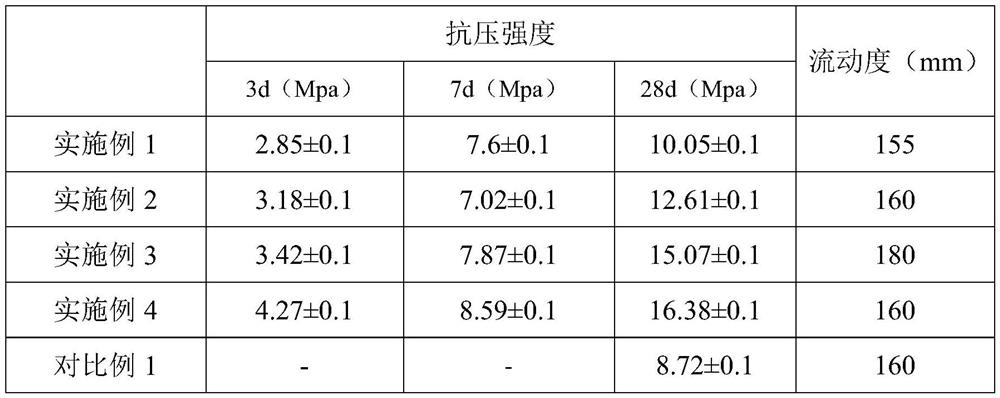

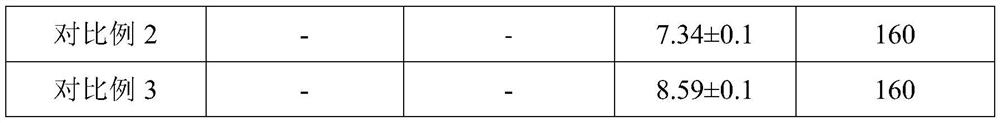

Embodiment 1

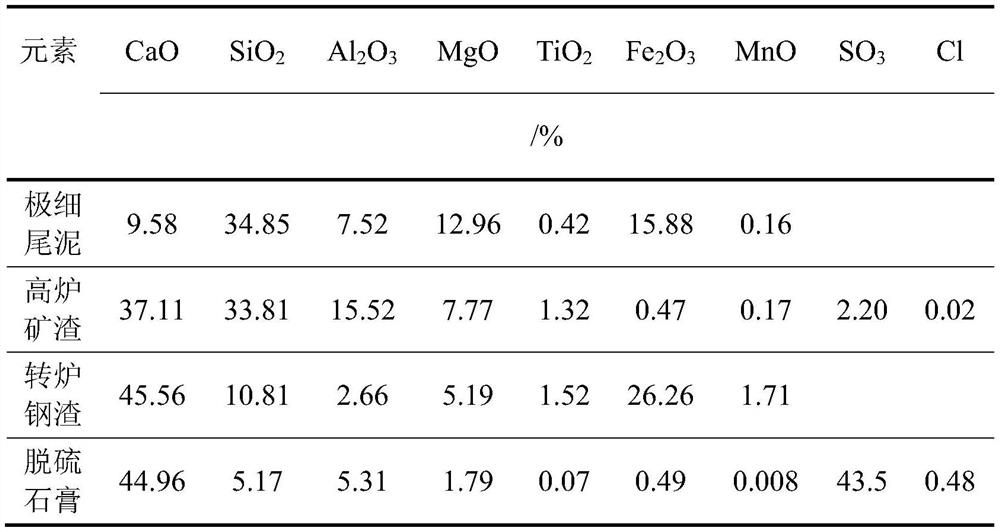

[0039] This embodiment provides a mortar filling test block containing ultrafine tailings, and its preparation method includes the following steps:

[0040](1) The raw materials of the cementitious material are weighed according to the following mass percentages: 35% of converter steel slag, 50% of blast furnace slag, 15% of desulfurized gypsum, and the desulfurized gypsum is ground to a specific surface area of 300m 2 / kg, the steel slag is ground to a specific surface area of 420m 2 / kg, grind the slag to a specific surface area of 500m 2 / kg;

[0041] (2) According to the mass ratio of cementitious material and ultrafine tailings is 1:4, take ultrafine tailings by weighing;

[0042] (3) Weigh the raw materials obtained in mixing steps (1) and (2), add water according to the slurry concentration of 74%, and stir evenly;

[0043] (4) After pouring and molding, it is maintained to different ages for compressive strength testing: according to GB17671-1999 "Cement Morta...

Embodiment 2

[0045] This embodiment provides a mortar filling test block containing ultrafine tailings, and its preparation method includes the following steps:

[0046] (1) Take the raw materials of the cementitious material according to the following mass percentages: 40% of converter steel slag, 40% of blast furnace slag, 20% of desulfurized gypsum, and grind the desulfurized gypsum until the specific surface area is 300m 2 / kg, the steel slag is ground to a specific surface area of 420m 2 / kg, grind the slag to a specific surface area of 500m 2 / kg;

[0047] (2) According to the mass ratio of cementitious material and ultrafine tailings is 1:4, take ultrafine tailings by weighing;

[0048] (3) Weigh the raw materials obtained in mixing steps (1) and (2), add water according to the slurry concentration of 76%, and stir evenly;

[0049] (4) After pouring and molding, it is maintained to different ages for compressive strength testing: according to GB17671-1999 "Cement Mortar Stren...

Embodiment 3

[0051] This embodiment provides a mortar filling test block containing ultrafine tailings, and its preparation method includes the following steps:

[0052] (1) The raw materials of the cementitious material are weighed according to the following mass percentages: 30% of converter steel slag, 60% of blast furnace slag, 10% of desulfurized gypsum, and the desulfurized gypsum is ground to a specific surface area of 300m 2 / kg, the steel slag is ground to a specific surface area of 420m 2 / kg, grind the slag to a specific surface area of 500m 2 / kg;

[0053] (2) According to the mass ratio of cementitious material and ultrafine tailings is 1:6, take ultrafine tailings by weighing;

[0054] (3) Weigh the raw materials obtained in mixing steps (1) and (2), add water according to the slurry concentration of 78%, and stir evenly;

[0055] (4) After pouring and molding, it is maintained to different ages for compressive strength testing: according to GB17671-1999 "Cement Mort...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com