Preparation method of tailings paste filling material

A technology of paste filling and tailings, which is applied in the field of filling materials, can solve the problems of poor adjustability of filling materials and lack of proportioning, and achieve the effects of abundant reserves, low production equipment and power consumption, and wide distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

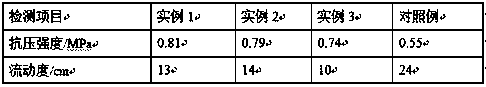

Examples

example 1

[0035] Put the tailing sand and mineral admixture in the cement mortar mixer, and stir at 200r / min at room temperature for 5 minutes to obtain the mixture; add the cement, aliphatic high-efficiency water reducer, and tap water to the mixture, and Stir at a low speed of 200r / min for 1min, then stir at a high speed of 600r / min for 3min, and let stand for 2min to obtain the tailings paste filling material. Tailings, cement, mineral admixture, aliphatic high-efficiency water reducer, and tap water have 100 parts by weight of tailings, 40 parts of cement, 50 parts of mineral admixture, 0.5 part of aliphatic high-efficiency water reducer, 60 servings of tap water. The specific preparation steps of the mineral admixture are as follows: put fly ash and silicon powder in a mixer at room temperature and stir for 2 hours at a speed of 100r / min to obtain mineral powder; mix hydroxypropyl methylcellulose, carboxymethylcellulose Add it to the mineral powder, and stir at 150r / min for 1.5h a...

example 2

[0037] Put the tailings and mineral admixture in the cement mortar mixer, and stir at 250r / min for 8 minutes at room temperature to obtain the mixture; add the cement, aliphatic high-efficiency water reducer, and tap water to the mixture, and Stir at a low speed of 250r / min for 1min, then stir at a high speed of 700r / min for 4min, and let stand for 3min to obtain the tailings paste filling material. The parts by weight of tailings, cement, mineral admixture, aliphatic high-efficiency water reducer, and tap water are 110 parts of tailings, 45 parts of cement, 55 parts of mineral admixture, 1.0 part of aliphatic high-efficiency water reducer, 70 servings of tap water. The specific preparation steps of the mineral admixture are: put fly ash and silicon powder in a mixer at room temperature and stir for 2 hours at a speed of 125r / min to obtain mineral powder; mix hydroxypropyl methylcellulose, carboxymethylcellulose Add it to the mineral powder and stir at 175r / min for 1.8h at ro...

example 3

[0039] Put the tailing sand and mineral admixture in the cement mortar mixer, and stir at 300r / min for 10 minutes at room temperature to obtain the mixture; add the cement, aliphatic high-efficiency water reducer, and tap water to the mixture, and Stir at a low speed of 300r / min for 2 minutes, then stir at a high speed of 800r / min for 5 minutes, and let stand for 4 minutes to obtain the tailings paste filling material. Tailings, cement, mineral admixture, aliphatic high-efficiency water reducer, and tap water have 120 parts by weight of tailings, 50 parts of cement, 60 parts of mineral admixture, 1.5 parts of aliphatic high-efficiency water reducer, 80 servings of tap water. The specific preparation steps of the mineral admixture are: put fly ash and silicon powder in a mixer at room temperature and stir for 3 hours at a speed of 150r / min to obtain mineral powder; mix hydroxypropyl methylcellulose, carboxymethylcellulose Add it to the mineral powder, and stir at 200r / min for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com